Anti-fingerprint glass organic silicon pressure-sensitive adhesive as well as preparation method and application thereof

A silicone pressure-sensitive adhesive and anti-fingerprint technology, applied in pressure-sensitive films/sheets, adhesives, etc., can solve the problems of low surface energy, instability, silicon transfer on the screen surface, etc., to improve temperature resistance and stability performance, to solve the effect of silicon transfer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

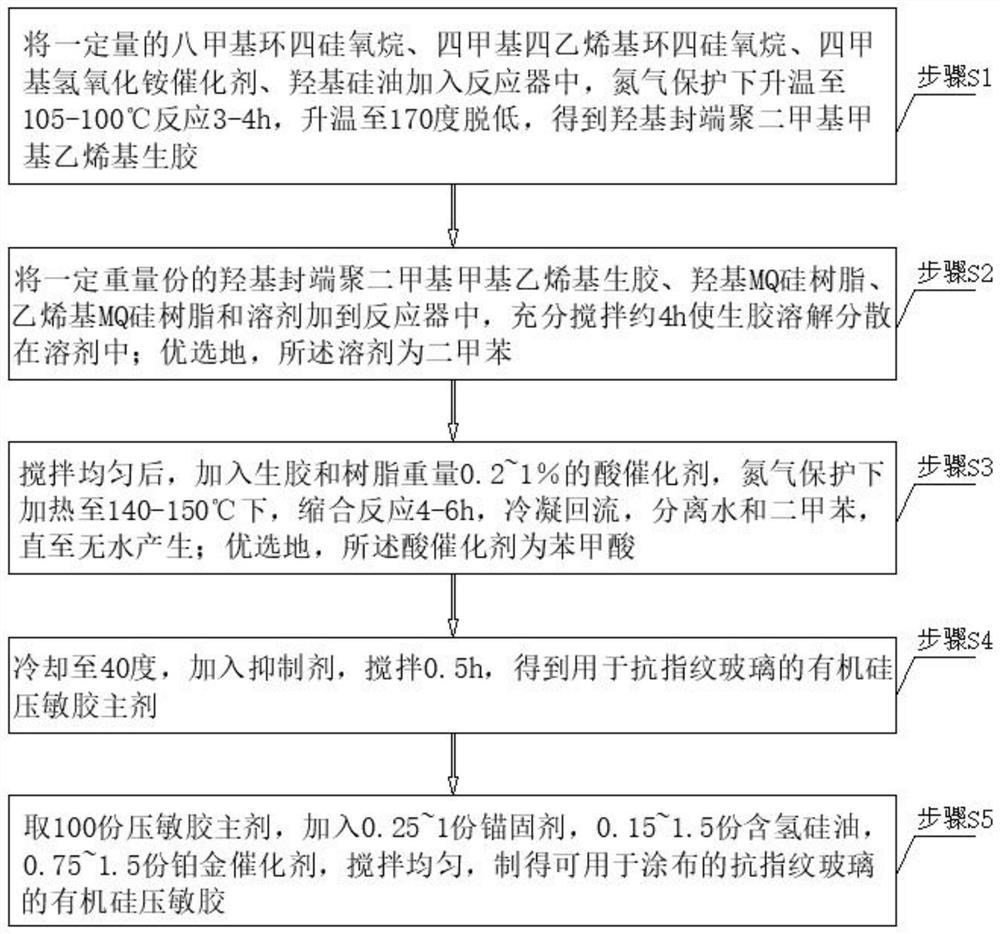

[0047] On the other hand, the preparation method of the organosilicon pressure-sensitive adhesive of the anti-fingerprint glass of the present invention comprises the following steps:

[0048] S1: Add the aforementioned hydroxyl-terminated polydimethylmethyl vinyl raw rubber, hydroxyl MQ silicone resin, vinyl MQ silicone resin and xylene into the reaction kettle, and stir for 4 hours to fully dissolve and disperse the hydroxyl raw rubber in the solvent.

[0049] S2: Add 0.2-1% benzoic acid catalyst of the total amount of silicone resin and raw rubber, heat to 140-150° C. under nitrogen protection, and perform condensation reaction for 5 hours until no water is produced.

[0050] S3: Cool to room temperature. Add inhibitor, anchoring agent, hydrogen-containing silicone oil, platinum catalyst, and stir evenly to obtain an organosilicon pressure-sensitive adhesive for anti-fingerprint glass.

[0051] Preparation of hydroxyl-terminated polydimethylmethylvinyl raw rubber.

[0052...

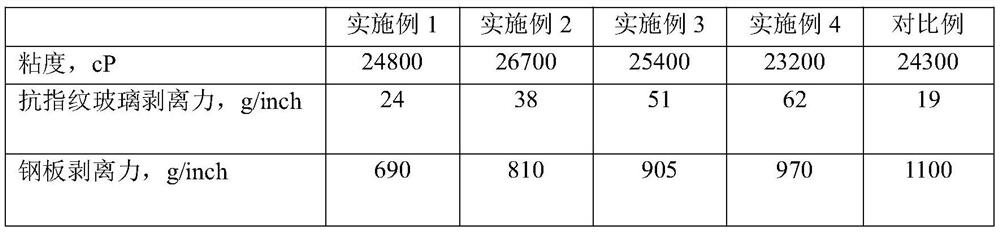

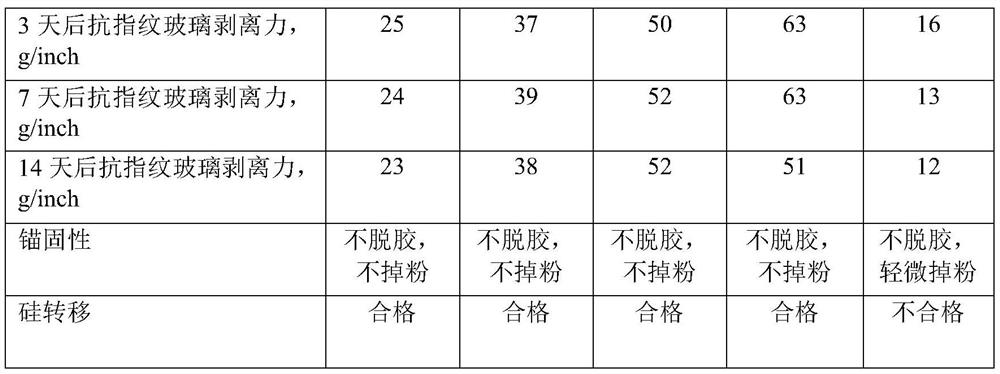

Embodiment 1

[0062] S1: Add 80g xylene, 10g hydroxyl MQ silicone resin, 62g vinyl MQ silicone resin, 33g raw rubber 1, 10g raw rubber 2, and 5g raw rubber 3 into the reactor, stir well for about 4h to dissolve and disperse the raw rubber in the reactor. in xylene.

[0063] S2: After stirring evenly, 0.4 g of benzoic acid was heated to 140-150° C. under nitrogen protection, and the condensation reaction was performed for 5 hours until no water was produced.

[0064] S3: Cool to 40°C, add 0.4g ethynyl cyclohexanol, 1g anchoring agent, 1.4g hydrogen-containing silicone oil, 2g platinum catalyst, stir for 0.5h, and prepare a silicone pressure-sensitive adhesive that can be used for coating anti-fingerprint glass .

Embodiment 2

[0066] S1: Add 80g xylene, 20g hydroxyl MQ silicone resin, 52g vinyl MQ silicone resin, 37g raw rubber 1, 8g raw rubber 2, and 3g raw rubber 3 into the reactor, stir well for about 4h to dissolve and disperse the raw rubber in the reactor. in xylene.

[0067] S2: After stirring evenly, 0.4 g of benzoic acid was heated to 140-150° C. under nitrogen protection, and the condensation reaction was performed for 5 hours until no water was produced.

[0068] S3: Cool to 40°C, add 0.4g ethynyl cyclohexanol, 1g anchoring agent, 2g hydrogen-containing silicone oil, 2g platinum catalyst, stir for 0.5h, and prepare a silicone pressure-sensitive adhesive for coating anti-fingerprint glass.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap