Automatic ore dressing monitoring method and system

A technology of mineral processing equipment and mine bins, which is applied in the field of automation, can solve problems such as technological process lagging, affecting product quality, and hindering enterprise growth, so as to achieve the effects of ensuring safety and personnel safety, reducing labor intensity of workers, and reducing jobs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

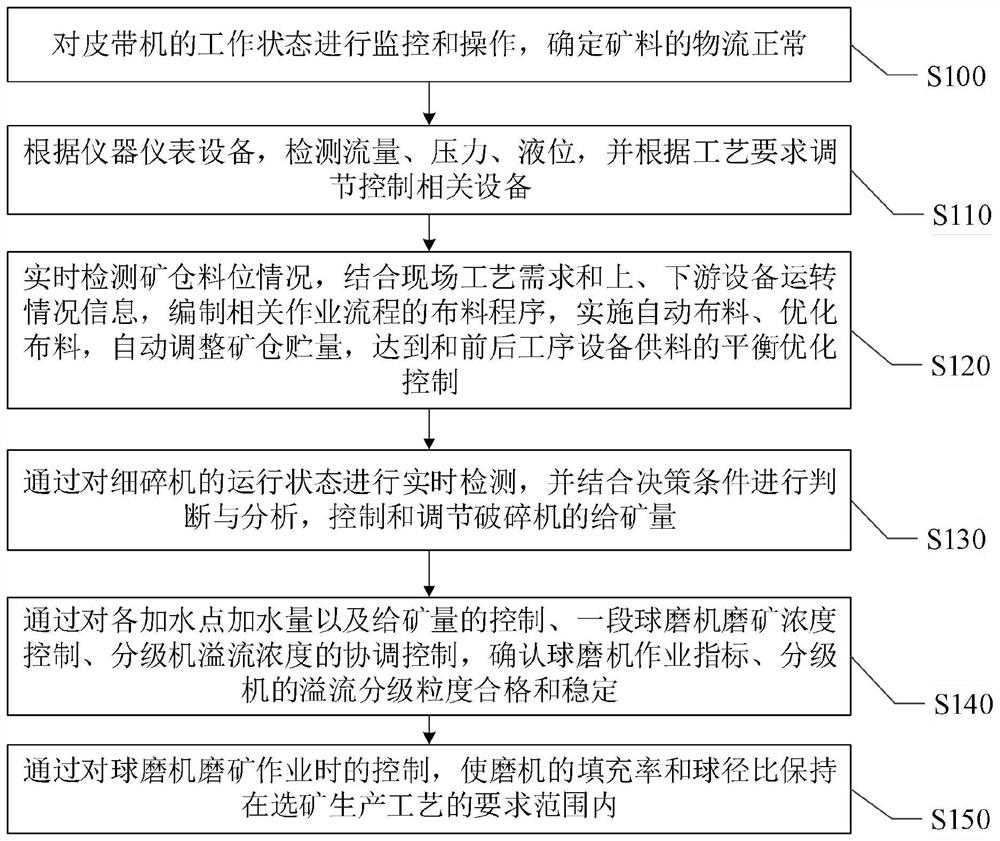

[0036] see figure 1 , figure 1 A schematic diagram of the steps of an automatic mineral processing monitoring method provided in the embodiment of the present application is as follows:

[0037] Step S100, monitor and operate the working state of the belt conveyor, and determine that the material flow of the ore material is normal;

[0038] In some embodiments, the belt conveyor is the key equipment for the ore dressing plant to realize the transportation of ore materials. materials, etc.) to monitor and operate, to ensure the normal logistics of mineral materials in the concentrator, and to provide reliable guarantee for the efficient operation of the equipment.

[0039] Step S110: Detect flow, pressure, and liquid level according to instrumentation equipment, and adjust and control related equipment according to process requirements;

[0040] In some embodiments, flow, pressure, liquid level are detected. Through the installed instrumentation equipment, the flow rate, pres...

Embodiment 2

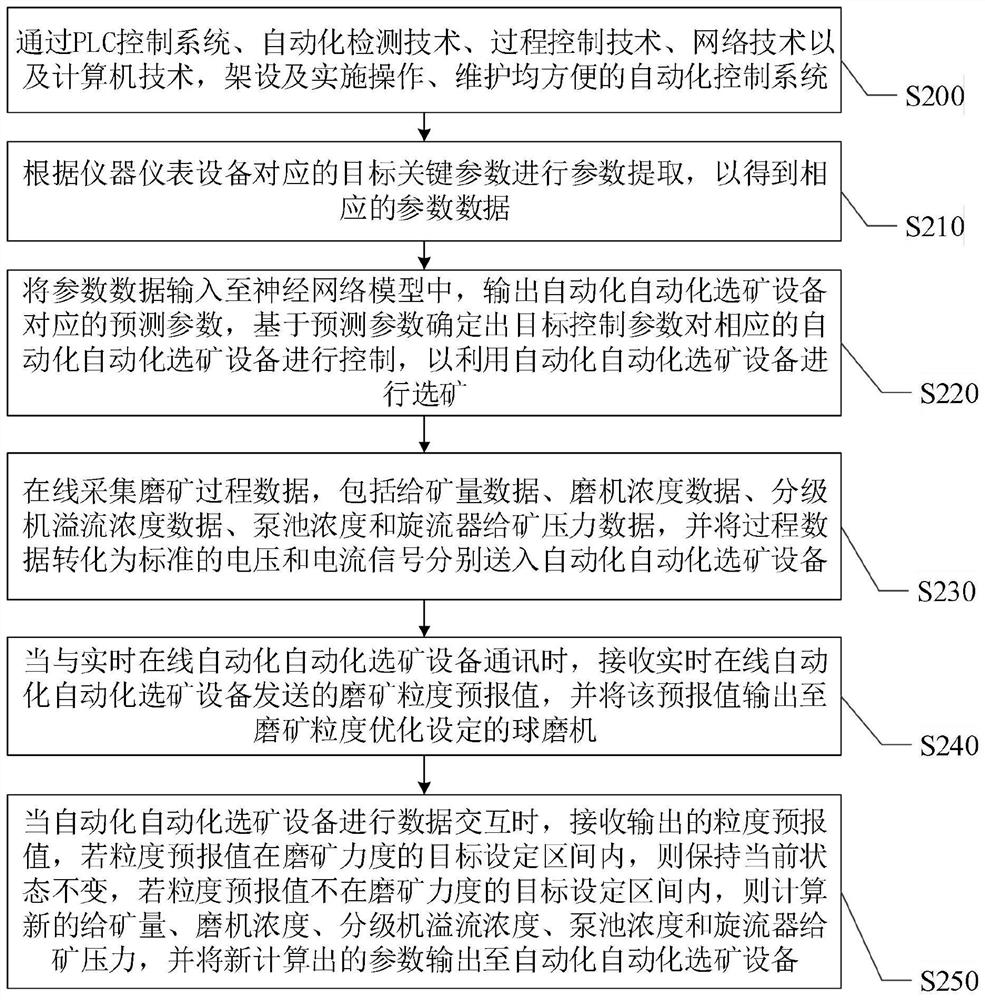

[0053] see figure 2 , figure 2 A schematic diagram of the detailed steps of an automatic mineral processing monitoring method provided in the embodiment of the present application is as follows:

[0054] In step S200, an automatic control system that is convenient for operation and maintenance is built and implemented through PLC control system, automatic detection technology, process control technology, network technology and computer technology.

[0055] In step S210, parameter extraction is performed according to the target key parameters corresponding to the instrumentation equipment to obtain corresponding parameter data.

[0056] Step S220, input the parameter data into the neural network model, output the predicted parameters corresponding to the automatic mineral processing equipment, and determine the target control parameters based on the predicted parameters to control the corresponding automatic mineral processing equipment, so as to use the automatic mineral pr...

Embodiment 3

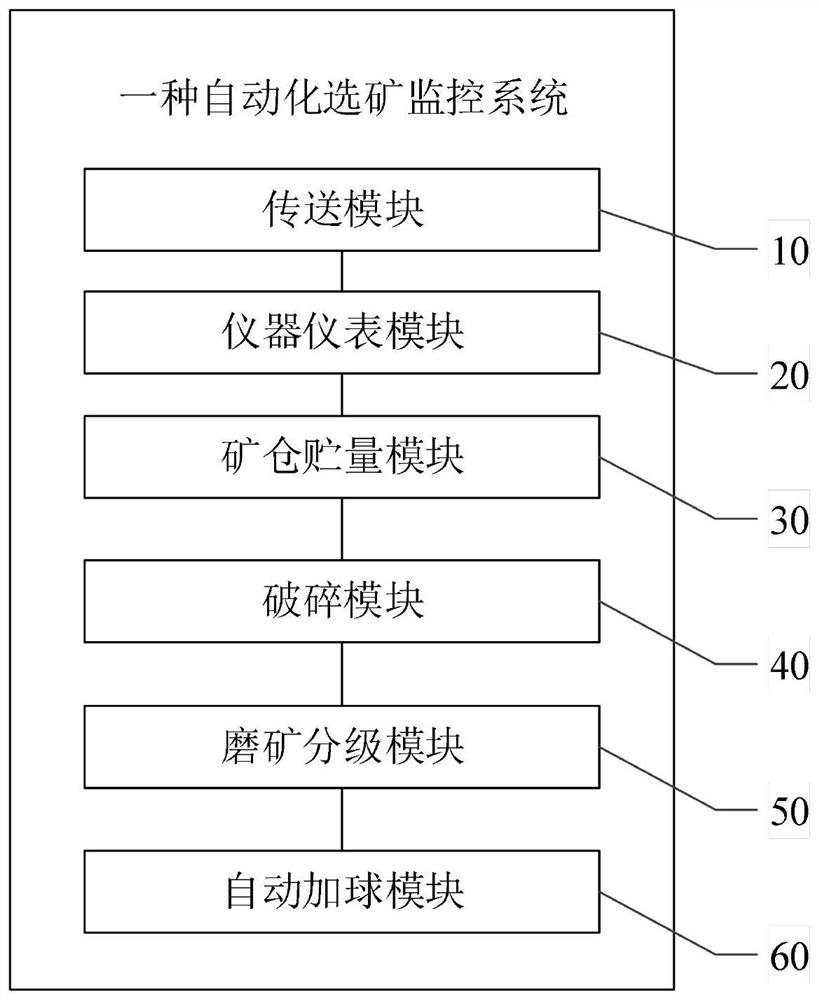

[0069] see image 3 , image 3 A schematic diagram of an automatic mineral processing monitoring system module provided in the embodiment of the present application is as follows:

[0070] The transmission module 10 is used to monitor and operate the working state of the belt conveyor to determine that the material flow is normal;

[0071] The instrumentation module 20 is used to detect the flow, pressure and liquid level according to the instrumentation equipment, and adjust and control the related equipment according to the process requirements;

[0072] The silo storage capacity module 30 is used to detect the material level of the silo in real time, and based on the on-site process requirements and information on the operation of upstream and downstream equipment, compile the distribution program of the relevant operation process, implement automatic distribution, optimize distribution, and automatically adjust the silo storage. Quantity, to achieve the balance and optim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com