A parallel continuous separation method and system for carbonate-rich heavy oil ore

A heavy oil ore and separation method technology, applied in the direction of solid separation, can solve the problems of high energy consumption, solvent leakage, etc., and achieve the effects of accelerating the reaction process, simple operation, and improving extraction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] A parallel continuous separation system and method for carbonate-rich heavy oil ore, the steps are as follows:

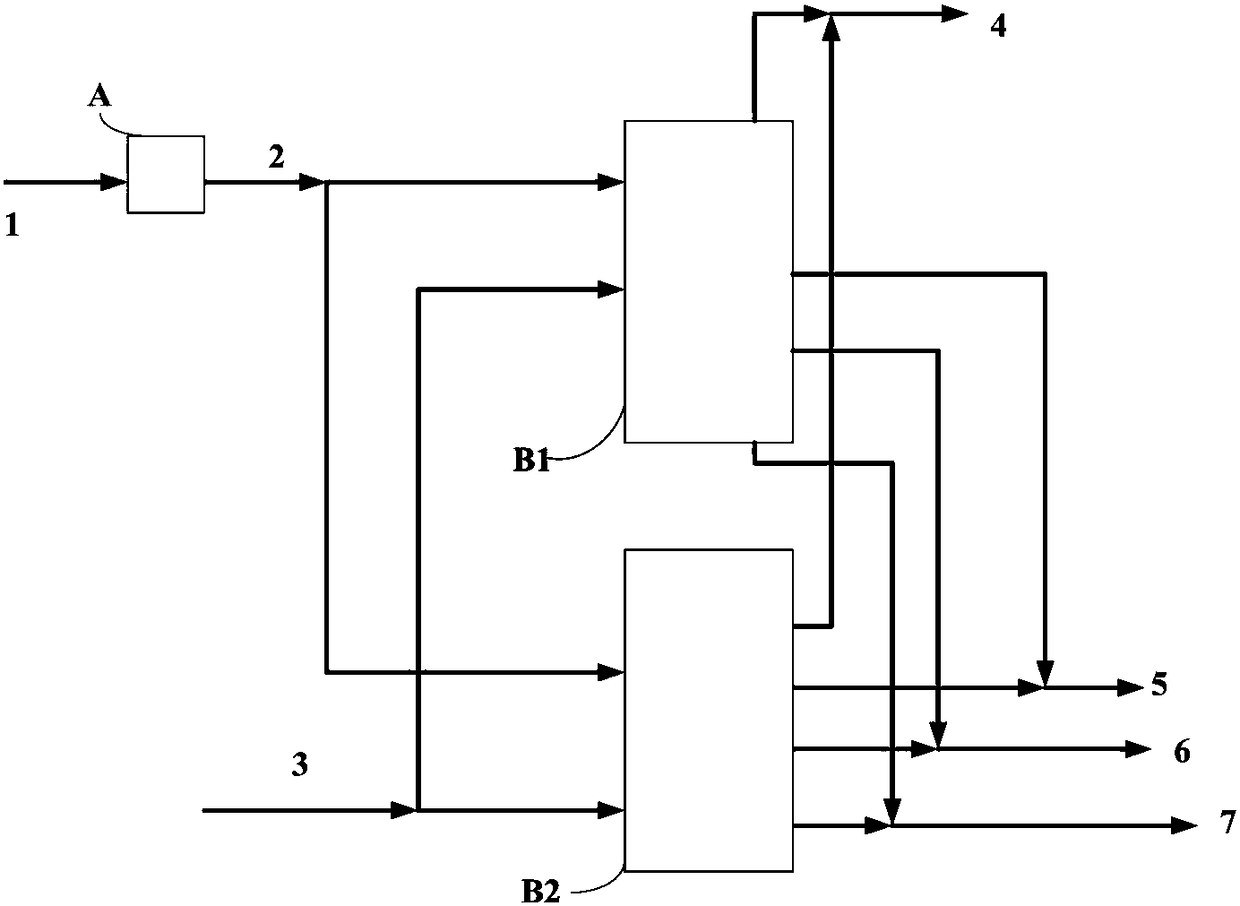

[0041]The oil sludge (carbonate content 33%, maximum particle size 5cm) pulverized by pulverizer A is fed into mixing-reactor B1 with 50kg oil sand ore at a speed of 5kg / min, and sulfuric acid and hydrogen fluoride with a concentration of 2 mol / liter Mix the acid mixture (1:1 by volume) according to the solid-to-liquid ratio of 1:3 (mass ratio), mix thoroughly at 95°C, stir and react for 40 minutes, and let stand for 5 minutes to take out the upper layer of asphalt foam, and at the same time discharge the middle The solution phase and the solid substance at the bottom; when the feeding of B1 is finished, feed to B2, B2 and B1 perform the same operation, and so on, and switch to B3, B4, and B5 respectively, such as figure 1 shown.

[0042] The recovery rate of the obtained asphalt foam reaches 99.7%, the residual solid sand and clay in the foam are less than ...

Embodiment 2

[0044] A parallel continuous separation system and method for carbonate-rich heavy oil ore, the steps are as follows:

[0045] The oil sand (carbonate content 77%, maximum particle size 2cm) pulverized by the pulverizer A is fed into the mixing reactor B1 at a speed of 10 kg / min. The acid mixture (1:1 by volume ratio) is fully mixed at 35°C according to the solid-to-liquid ratio of 1:30 (mass ratio), ultrasonically reacted for 100 minutes, and left to stand for 5 minutes to take out the upper layer of asphalt foam, and at the same time discharge the middle The solution phase and the solid substance at the bottom; when the feeding of B1 is finished, feed to B2, B2 and B1 perform the same operation, and so on, and switch to B3, B4, and B5 respectively, such as figure 1 shown.

[0046] The recovery rate of the obtained asphalt foam reaches 99.7%, the residual solid sand grains and clay in the foam are less than 37.5% of the total mass of the foam, and the water content is less t...

Embodiment 3

[0048] A parallel continuous separation system and method for carbonate-rich heavy oil ore, the steps are as follows:

[0049] The oil shale (carbonate content 63%, maximum particle size 1.5cm) that pulverizes through pulverizer A is input 50kg oil sands ore to mixing reactor B1 with the speed of 10kg / min, and concentration is the phosphoric acid of 3 mol / liter according to The solid-liquid ratio is 1:5 (mass ratio), fully mixed at 5°C, microwave-enhanced (1.5KW) for 100 minutes, and allowed to stand for 5 minutes to take out the upper layer of asphalt foam, and at the same time discharge the middle solution phase and the solid substance at the bottom; After the feeding of B1 is finished, feed to B2, B2 and B1 perform the same operation, and so on, switch to B3, B4, and B5 respectively, such as figure 1 shown.

[0050] The recovery rate of the obtained asphalt foam reaches 99.2%, the residual solid sand grains and clay in the foam are less than 33% of the total mass of the fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com