Glass discharging system for hollow glass production

A glass and hollow technology, applied in the field of glass unloading system, can solve the problems of insufficient unloading efficiency of glass stacking, and achieve the effect of saving control steps, improving position accuracy and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

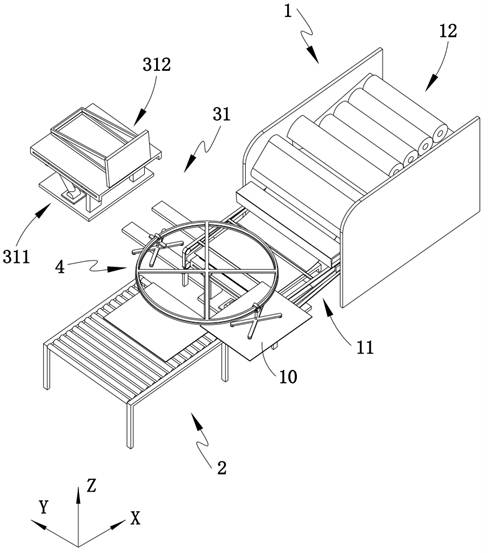

[0066] like Figure 1-5 As shown, the present embodiment provides a glass unloading system for the production of insulating glass, including a paper laying machine 1, and also includes:

[0067] The roller table unit 2, the roller table unit 2 used for conveying the glass 10 to the paper laying machine 1 is arranged on one side of the paper feeding end of the paper laying machine 1;

[0068] a packaging stand 3, for carrying the glass 10, is arranged between the roller table unit 2 and the layer 1; and

[0069] The stacking unit 4, which stacks the glass 10 on the roller table unit 2 to the stacking unit 4 on the packaging rack 3 is arranged between the roller table unit 2 and the packaging rack 3;

[0070] The stacking unit 4 includes:

[0071] Bracket 41, a conveying track 42 is fixed on the bracket 41, and the conveying track 42 passes above the packaging stand 3 and the roller table unit 2;

[0072] Transporting assemblies 43, at least one group of transporting assembli...

Embodiment 2

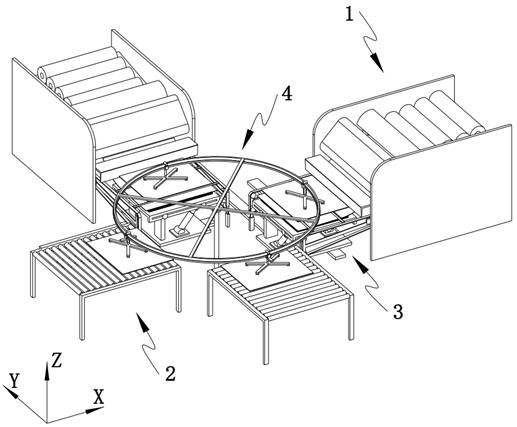

[0102] like Figure 1-3 , 9-11, in which the same or corresponding components as in the first embodiment are given the corresponding reference numerals as in the first embodiment. For the sake of brevity, only the differences from the first embodiment are described below. The difference between the second embodiment and the first embodiment is:

[0103] The paper laying machine 1 includes:

[0104] The pulling mechanism 11, the pulling mechanism 11 for guiding the spacer paper to the surface of the stacked glass 10 is arranged on both sides of the packaging platform 3 and is connected to the paper laying machine 1 in a driving connection;

[0105] The paper feeding mechanism 12, the paper feeding mechanism 12 for supplementing the spacer paper in the paper laying machine 1 is fixed above the paper laying machine 1; and

[0106] The lifting assembly 13 is fixed under the traction mechanism 11 and used to adjust the height of the traction mechanism 11 .

[0107] In this embod...

Embodiment 3

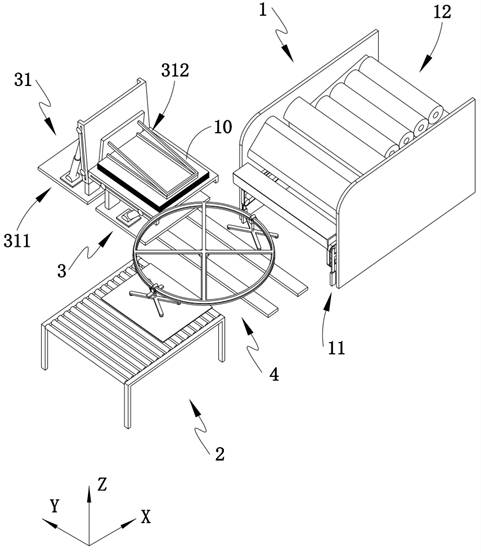

[0121] like Figure 1-3 As shown, the same or corresponding components as those in the first embodiment are given the corresponding reference numerals as in the first embodiment. For the sake of brevity, only the points of difference from the first embodiment are described below. The difference between the third embodiment and the first embodiment is:

[0122] Also includes a transfer assembly 31 for transferring the stacked glass 10, and the transfer assembly 31 is fixed on the bottom of the packaging platform 3;

[0123] The transfer assembly 31 includes a turning part 311 for adjusting the posture of the packaging platform 3 and a loading part 312 for receiving the packaging stack glass 10 .

[0124] In the present embodiment, after the glass 10 on the packaging rack 3 is stacked to the capacity of one packaging unit, the inverting part 311 is installed, for example, on the hydraulic rod group and the sliding table at the bottom of the packaging rack 3, so that the packagi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com