High-temperature-resistant radiation-resistant high-entropy alloy and preparation method thereof

A high-entropy alloy and anti-irradiation technology, applied in the direction of additive manufacturing, reducing greenhouse gases, improving energy efficiency, etc., can solve the problem of insufficient interface wettability, high-temperature mechanical properties of high-entropy alloys do not increase but decrease, material strength and plasticity The effect of improving high temperature mechanical properties and improving radiation resistance performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

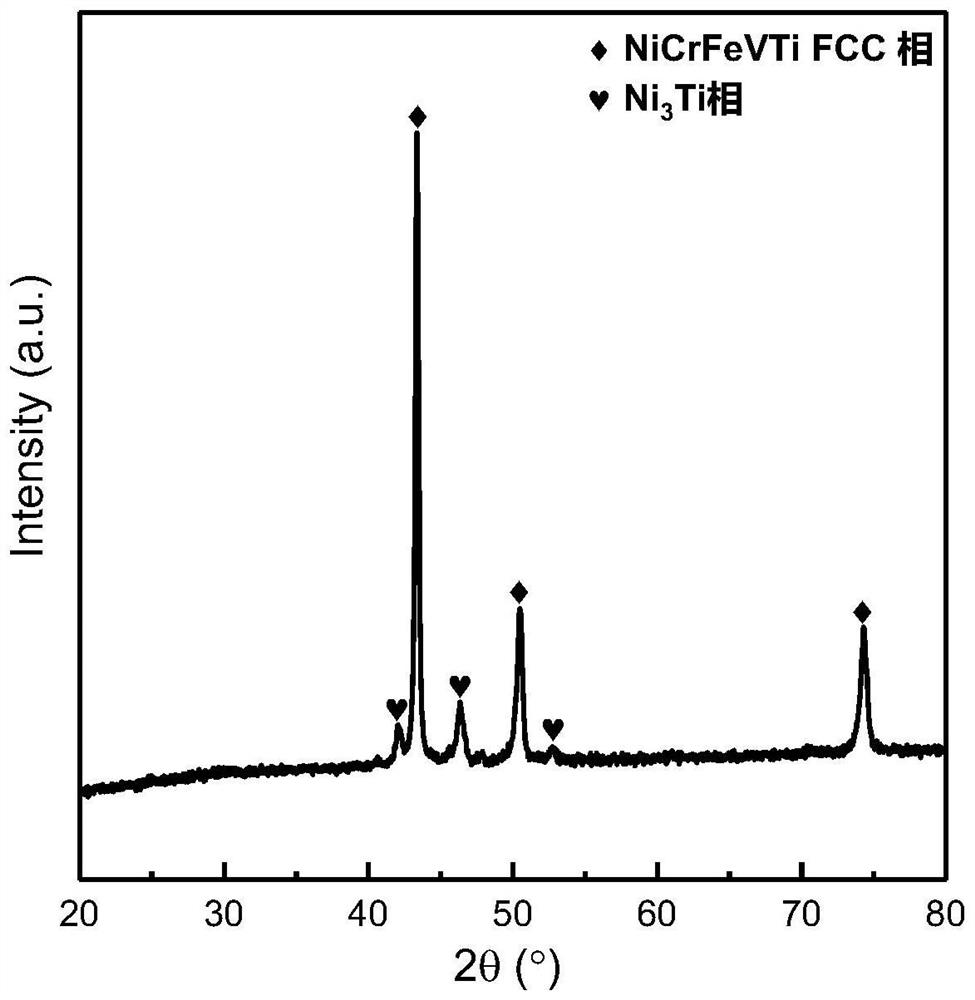

[0072] This embodiment provides a high-temperature-resistant and radiation-resistant high-entropy alloy, wherein the Ni and Fe components are in the upper range, the Cr and Ti components are in the lower range, and the additive manufacturing process parameters are in the lower range. The preparation method includes the following steps:

[0073] S1: After removing the oxide scale on the surface of Ni, Cr, Fe, V and Ti metals, weigh them according to the proportion of alloy components, add the weighed Ni, Cr, Fe, V and Ti metals into a vacuum arc furnace, and smelt until all the The metal is completely melted and fused evenly; the mole fractions of Ni, Cr, Fe, V and Ti are 40:10:35:10:5 respectively, and the melting temperature is 1700°C;

[0074] S2: Use a manipulator to turn the molten and solidified ingot over and smelt again, and the re-melting temperature is 1700°C, and this cycle is repeated 4 times to obtain an alloy ingot;

[0075] S3: pulverizing the alloy ingot to obta...

Embodiment 2

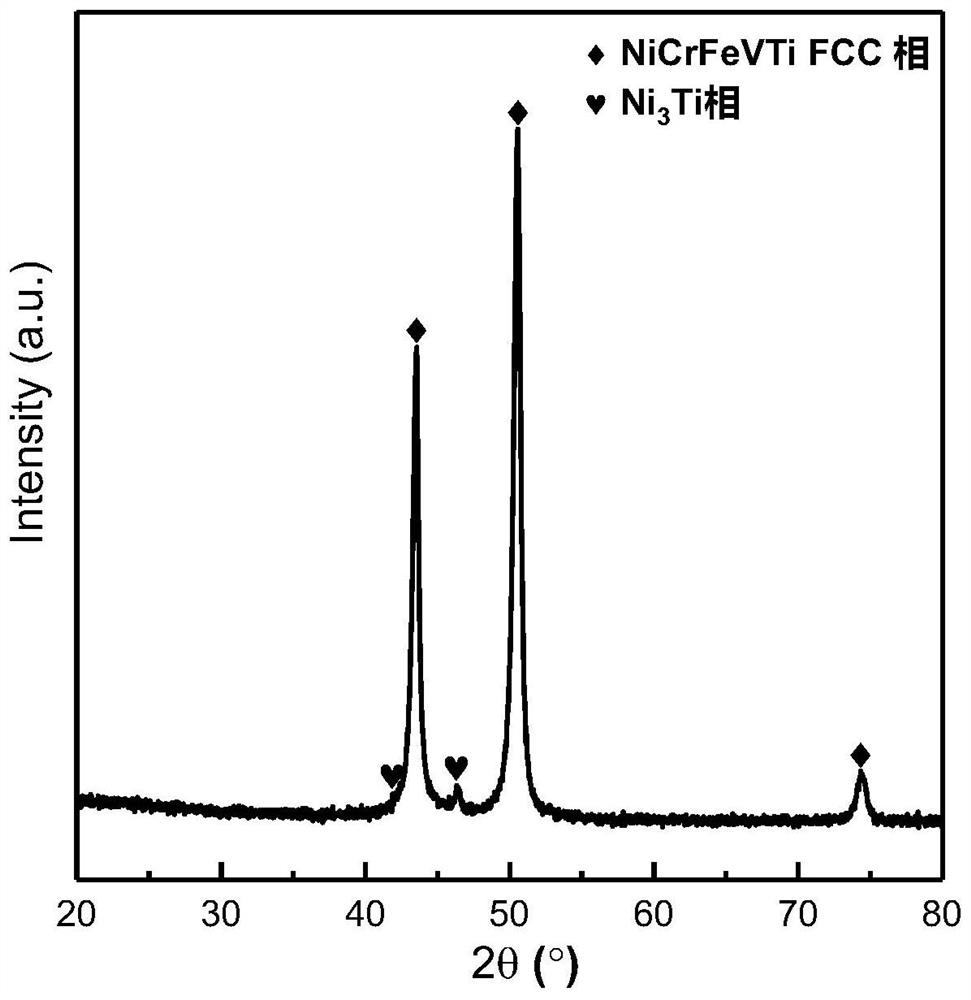

[0078] This embodiment provides a high-entropy alloy, the material composition of which is different from that of Embodiment 1, the Ni and Fe components are in the lower range, the Cr and Ti components are in the upper range, and the additive manufacturing process parameters are the same. Its preparation method comprises the following steps:

[0079] S1: After removing the oxide scale on the surface of Ni, Cr, Fe, V and Ti metals, weigh them according to the proportion of alloy components, add the weighed Ni, Cr, Fe, V and Ti metals into a vacuum arc furnace, and smelt until all the The metal is completely melted and fused evenly; the mole fractions of Ni, Cr, Fe, V and Ti are 30:20:25:15:10 respectively, and the melting temperature is 1800°C;

[0080] S2: Use a manipulator to turn the molten and solidified ingot over and smelt again, and the re-melting temperature is 1800°C, and this cycle is repeated 3 times to obtain an alloy ingot;

[0081] S3: pulverizing the alloy ingot...

Embodiment 3

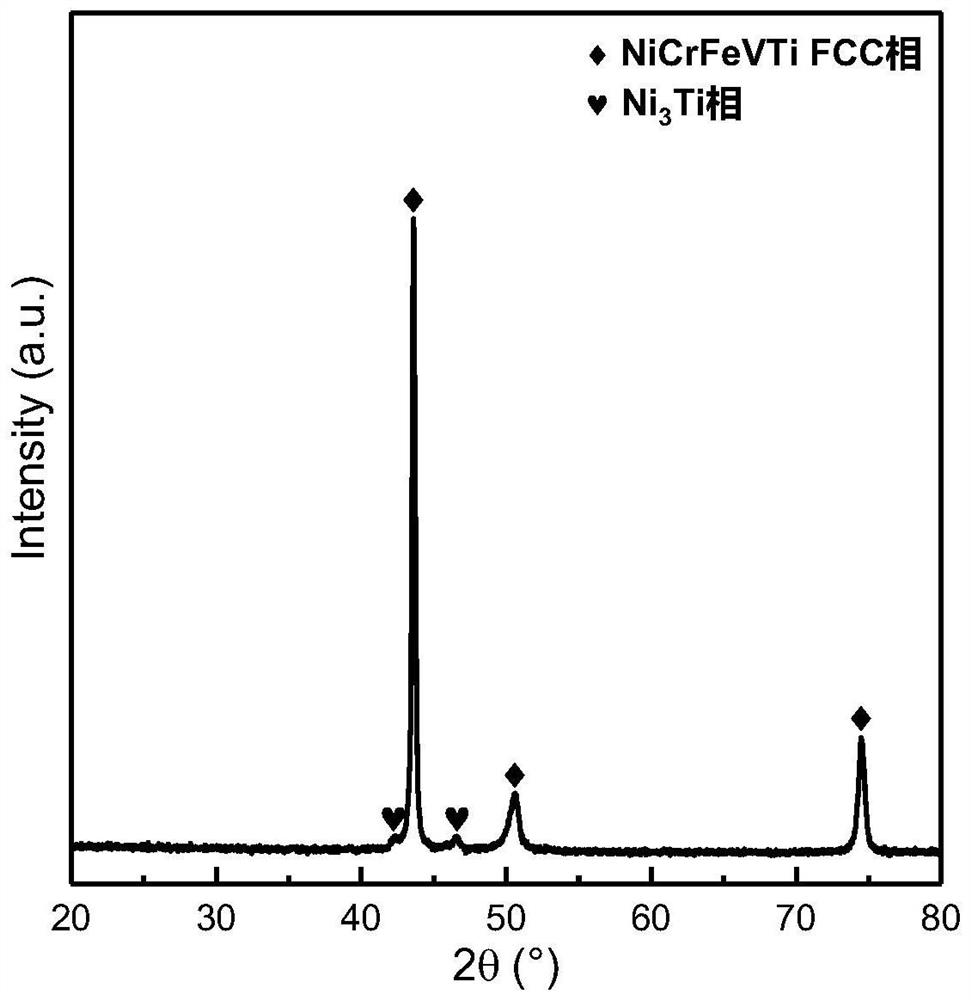

[0084] This embodiment provides a high-entropy alloy whose material composition is the same as that of Embodiment 1, but the additive manufacturing process parameters are in the upper range. Its preparation method comprises the following steps:

[0085] S1: After removing the oxide scale on the surface of Ni, Cr, Fe, V and Ti metals, weigh them according to the proportion of alloy components, add the weighed Ni, Cr, Fe, V and Ti metals into a vacuum arc furnace, and smelt until all the The metal is completely melted and fused evenly; the mole fractions of Ni, Cr, Fe, V and Ti are respectively 40:10:35:10:5, and the melting temperature is 1500°C;

[0086] S2: Use a manipulator to turn over the molten and solidified ingot and smelt again, and the re-melting temperature is 1500°C, and this cycle is repeated 5 times to obtain an alloy ingot;

[0087]S3: pulverizing the alloy ingot to obtain powder particles with a particle size of 50-150 μm, and the pulverizing process adopts gas...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Average grain size | aaaaa | aaaaa |

| Average grain size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com