Display panel manufacturing method and display panel

A technology for display panels and manufacturing methods, applied in the fields of instruments, nonlinear optics, optics, etc., which can solve problems such as long etching time, reduced production capacity, and difficulty in controlling the organic flat layer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

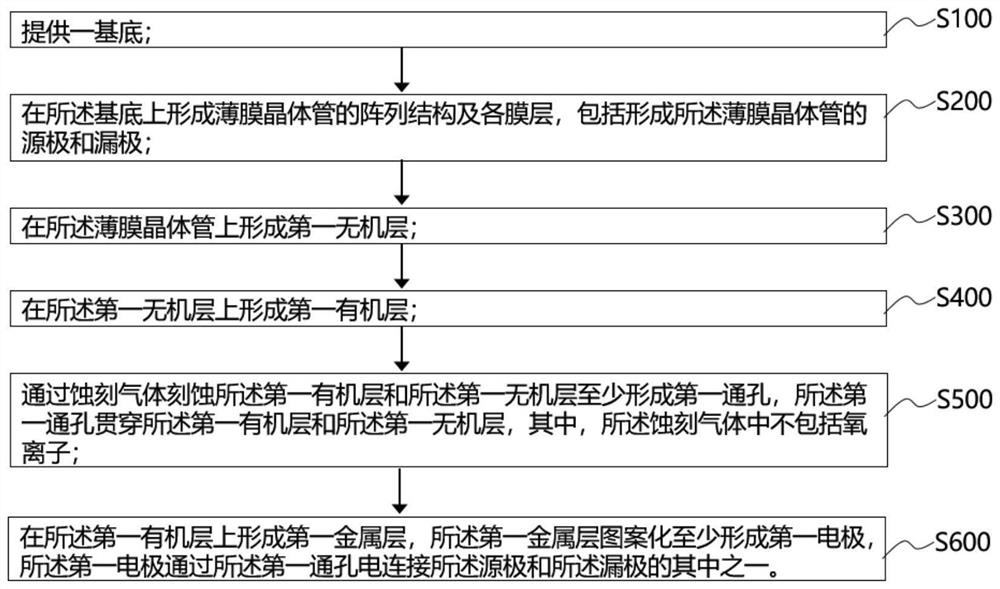

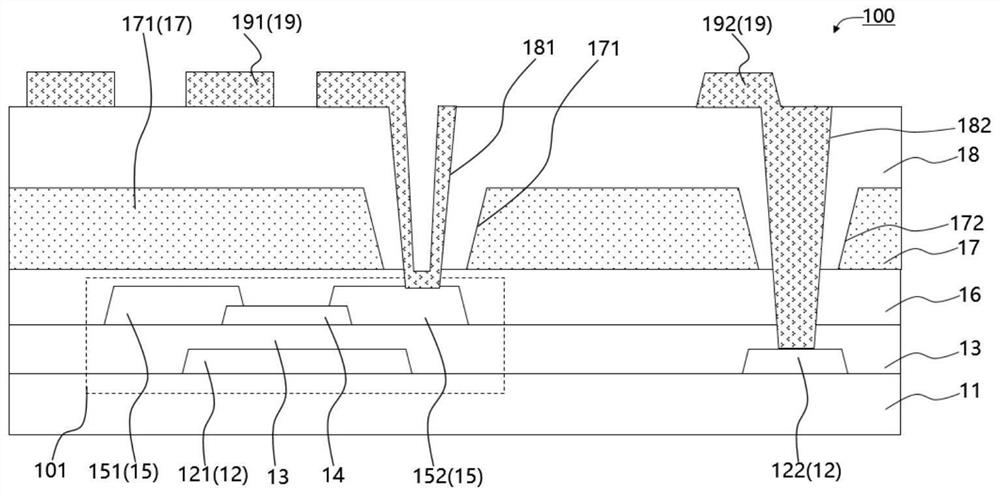

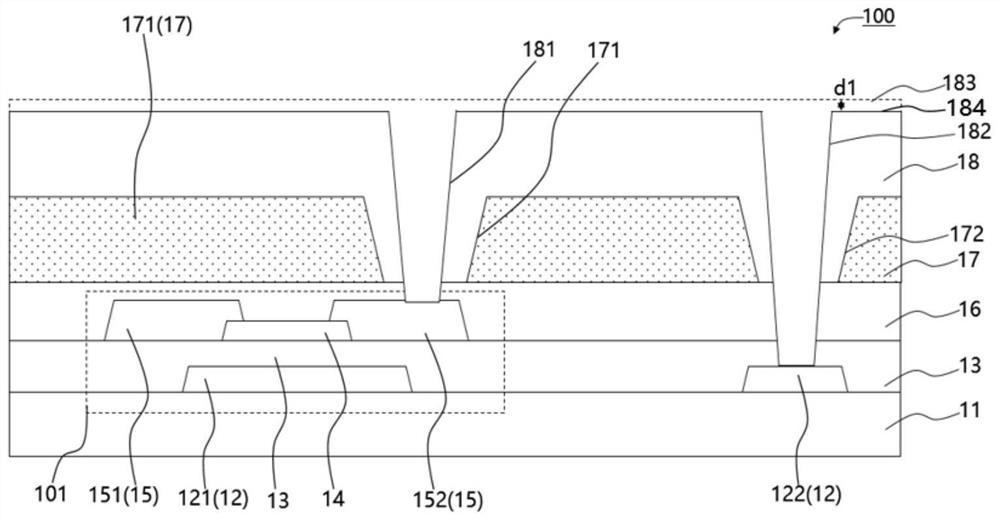

[0047] see Figure 1 to Figure 3 , figure 1 A first schematic flowchart of a method for manufacturing a display panel provided by an embodiment of the present application; figure 2A schematic cross-sectional structure diagram of a partial structure of a display panel provided in an embodiment of the present application, image 3 This is a schematic diagram of an intermediate process of a method for manufacturing a display panel according to an embodiment of the present application.

[0048] An embodiment of the present application provides a method for manufacturing a display panel, including: providing a substrate; forming an array structure of thin film transistors and each film layer on the substrate, including forming a source electrode and a drain electrode of the thin film transistor; forming on the thin film transistor a first inorganic layer; a first organic layer is formed on the first inorganic layer; at least a first through hole is formed by etching the first or...

Embodiment 2

[0071] This embodiment is the same as or similar to the above-mentioned embodiment, and the differences further describe the features of the manufacturing method of the display panel.

[0072] see Figure 4 , Figure 4 This is a second schematic flow chart of a method for manufacturing a display panel provided in an embodiment of the present application.

[0073] In some embodiments, when at least the first through hole is formed by etching the first organic layer and the first inorganic layer with an etching gas, the etching gas includes fluorine ions.

[0074] Specifically, in step S500, when at least the first through holes 181 are formed by etching the first organic layer 18 and the first inorganic layer 16 with an etching gas, the etching gas includes fluorine ions.

[0075] Specifically, the etching gas contains fluorine ions, and the etching gas may include nitrogen trifluoride (NF3), carbon tetrafluoride (CF4), and the like.

[0076] Specifically, the etching gas co...

Embodiment 3

[0084] This embodiment is the same as or similar to the above-mentioned embodiment, and the differences further describe the features of the manufacturing method of the display panel.

[0085] see Figure 5 , Figure 5 A third schematic flow diagram of a method for manufacturing a display panel provided in an embodiment of the present application.

[0086] In some embodiments, further comprising between forming the first inorganic layer on the array structure of the thin film transistor and forming the first organic layer on the first inorganic layer: forming a color blocking layer on the first inorganic layer; wherein, When the first organic layer is formed on the first inorganic layer, the first organic layer is formed on the color resist layer; wherein, when at least the first through hole is formed by etching the first organic layer and the first inorganic layer with an etching gas, the first organic layer is formed on the color resist layer. A through hole also penetrat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com