Multi-phase permanent magnet synchronous motor winding design method and motor

A technology of permanent magnet synchronous motor and design method, which is applied to synchronous motors, windings, motors, etc. Problems such as high power density can achieve the effect of maximizing the reluctance torque component, eliminating high-amplitude low-order harmonics, and reducing amplitude harmonic components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] This embodiment provides a method for designing windings of a multi-phase permanent magnet synchronous motor with high fault tolerance.

[0039] A high fault-tolerant multi-phase permanent magnet synchronous motor winding design method, which is applied to the winding winding method on the inner stator or the outer stator of the motor, the winding winding method adopts the fractional slot phase group concentrated winding method, and the fractional slot phase group winding method is adopted. The concentrated winding method of the phase group includes the inner and outer stators connected in the same way or in different ways;

[0040] The same connection method is that both the inner and outer stators adopt the star-star connection method, the different connection methods are that the outer stator adopts the star-star connection method, and the inner stator adopts the star-pentagon star connection method.

[0041] Specifically, a polyphase permanent magnet synchronous mot...

Embodiment 2

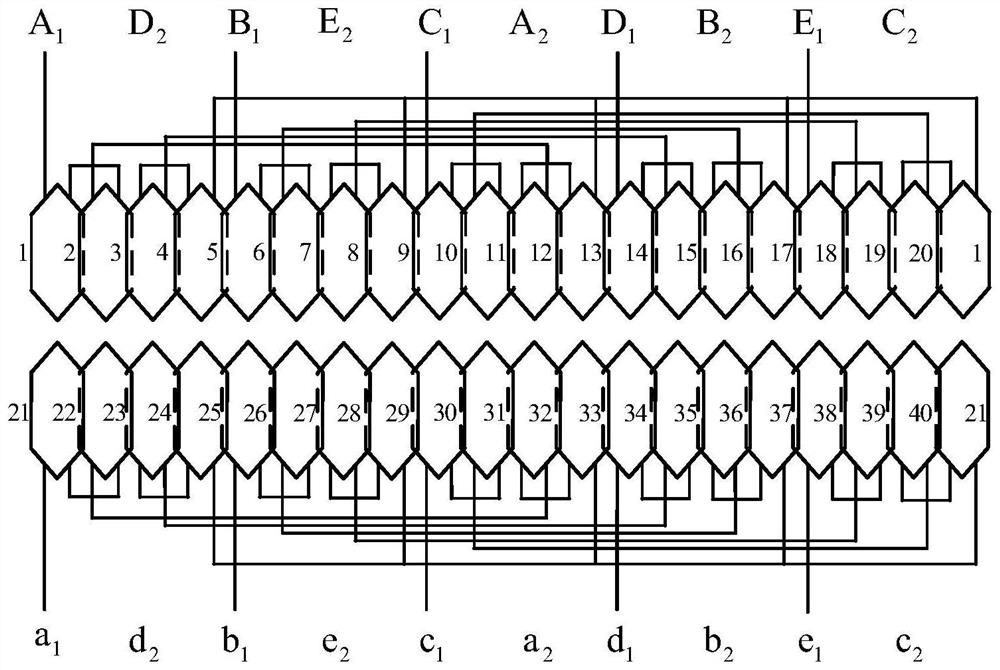

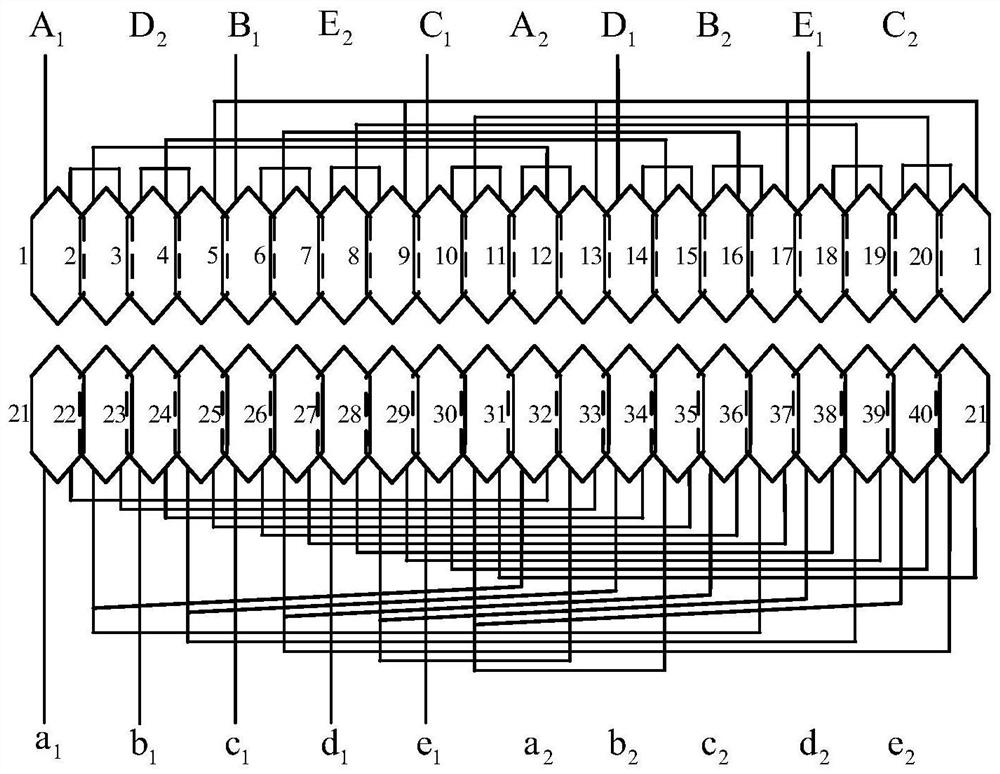

[0056] like figure 2 As shown, the outer stator winding of the second winding method is as follows:

[0057] A 1 : A 1 -1, 1-2, 2-3, 3-2, 2-12, 12-11, 11-12, 12-13, 13-A 2 ;

[0058] B 1 :B 1 -5, 5-6, 6-7, 7-6, 6-16, 16-15, 15-16, 16-17, 17-B 2 ;

[0059] C 1 :C 1 -9, 9-10, 10-11, 11-10, 10-20, 20-19, 19-20, 20-1, 1-C 2 ;

[0060] D 1 :D 1 -13, 13-14, 14-15, 15-14, 14-4, 4-3, 3-4, 4-5, 5-D 2 ;

[0061] E 1 :E 1 -17, 17-18, 18-19, 19-18, 18-8, 8-7, 7-8, 8-9, 9-E 2 .

[0062] Wherein, the winding of the inner stator main winding of the second winding method is as follows:

[0063] a 1 : a 1 -21, 21-22, 22-32, 32-31, 31-a 2 ;

[0064] b 1 :b 1 -23, 23-24, 24-34, 34-33, 33-b 2 ;

[0065] c 1 :c 1 -25, 25-26, 26-36, 36-35, 35-c 2 ;

[0066] d 1 :d 1 -27, 27-28, 28-38, 38-37, 37-d 2 ;

[0067] e 1 : e 1 -29, 29-30, 30-40, 40-39, 39-e 2 .

[0068] The winding method of the secondary winding is as follows:

[0069] a 1 -22, 22-23, 23-a 2 , a ...

Embodiment 3

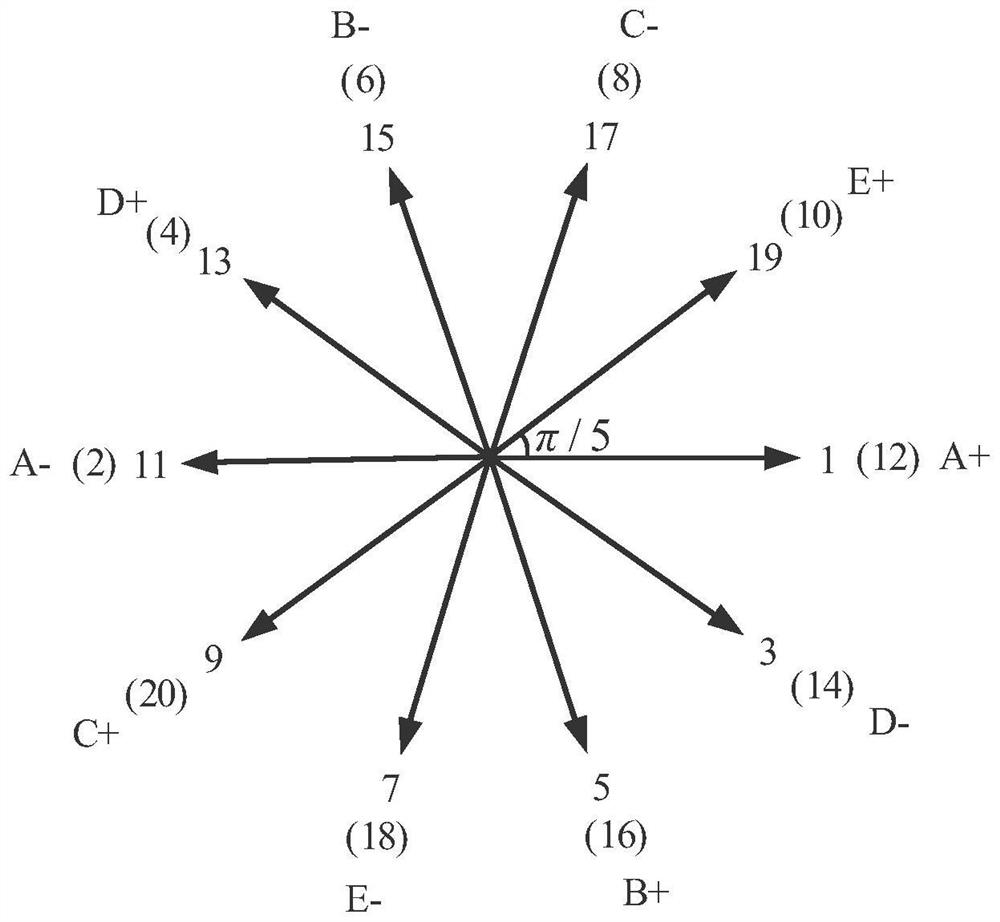

[0072] Combined with the first embodiment, in order to achieve the high performance of the permanent magnet synchronous motor, the stator winding is in a concentrated winding mode, the purpose is to improve the winding coefficient and reduce the end winding, and improve the efficiency of the motor, and each phase winding adopts a modular design. The two sets of stator windings of the five-phase motor can be independently controlled, and the dual five-phase control strategy can further improve the fault tolerance of the motor. The design principle of this embodiment is as follows:

[0073] The windings of the five-phase permanent magnet synchronous motor are connected according to Figure 4(a) and Figure 4(b).

[0074] First determine the pole-slot fit, the formula is based on:

[0075]

[0076] Among them, Z is the number of stator slots, GCD(Z, 2p) is the greatest common divisor of the number of stator slots and the number of poles, and C is any positive integer. The pole...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com