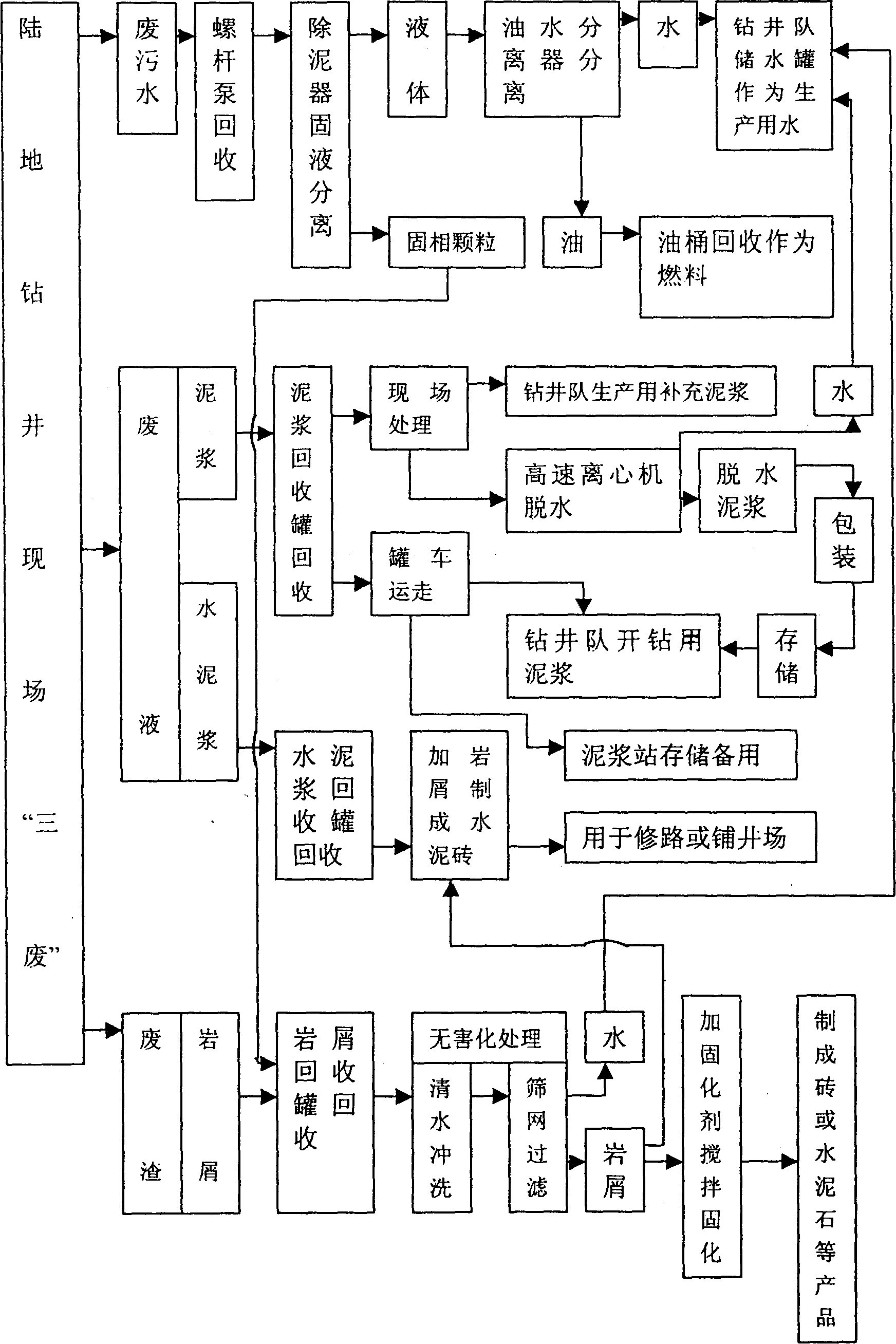

Process for reclaiming the three wastes in site of drilling well on land

An on-site, three-waste technology, used in separation methods, solid waste removal, dehydration/drying/concentrated sludge treatment, etc. , material resources and costs, etc., to achieve the effect of being suitable for promotion and application, easy to implement and simple equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The implementation of the present invention will be further described below in conjunction with the accompanying drawings.

[0017] The device that the present invention implements adopted, equipment specification model are as follows:

[0018] Screw pump 90WLB-3012 for sewage recovery;

[0019] Sewage solid-liquid separator for mud desilting 2CNQ-120×8;

[0020] Oil-water separator is a cylindrical general engineering container with a height of 1m and a diameter of 0.5m;

[0021] Clean water drainage pump IS50-32-160 centrifugal pump;

[0022] Modified centrifuge LW400 centrifuge for mud dehydration;

[0023] It is also equipped with a concrete mixer, as well as tankers and trucks for transporting mud and solidified materials, with a volume of 40m 3 1 square mud recovery tank, 20m 3 One cement slurry recovery tank, one cuttings recovery tank, two 200-liter oil drums.

[0024] Indicator category

[0025] The main components of the MTC curing agent used...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com