Magnetostatic wave element and its manufacturing method

A manufacturing method and magnetostatic technology, applied in electrical components, waveguide-type devices, chemical instruments and methods, etc., can solve the problems of deteriorating the characteristics of magnetostatic wave components, and achieve the effect of excellent frequency characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0037] Table 1

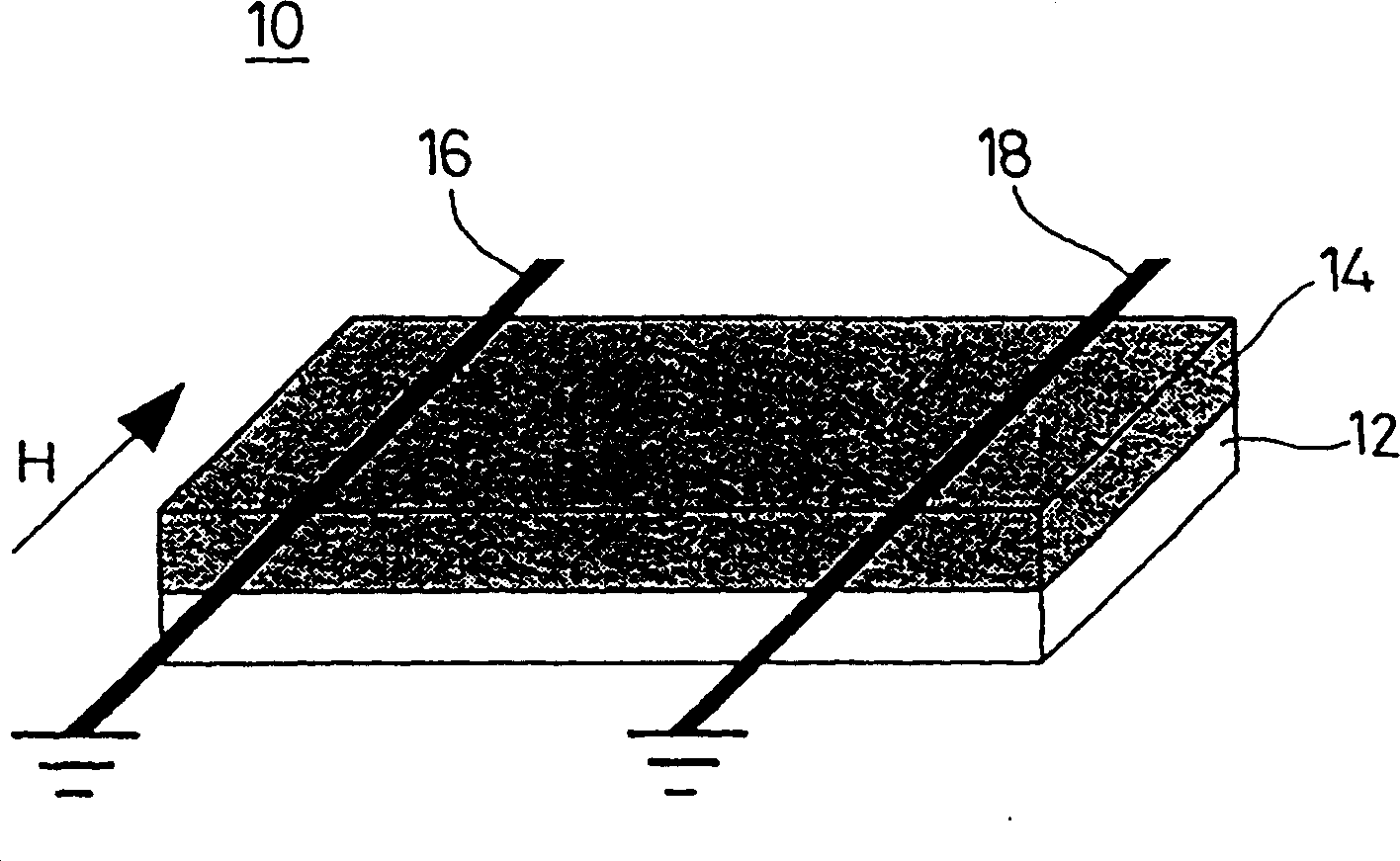

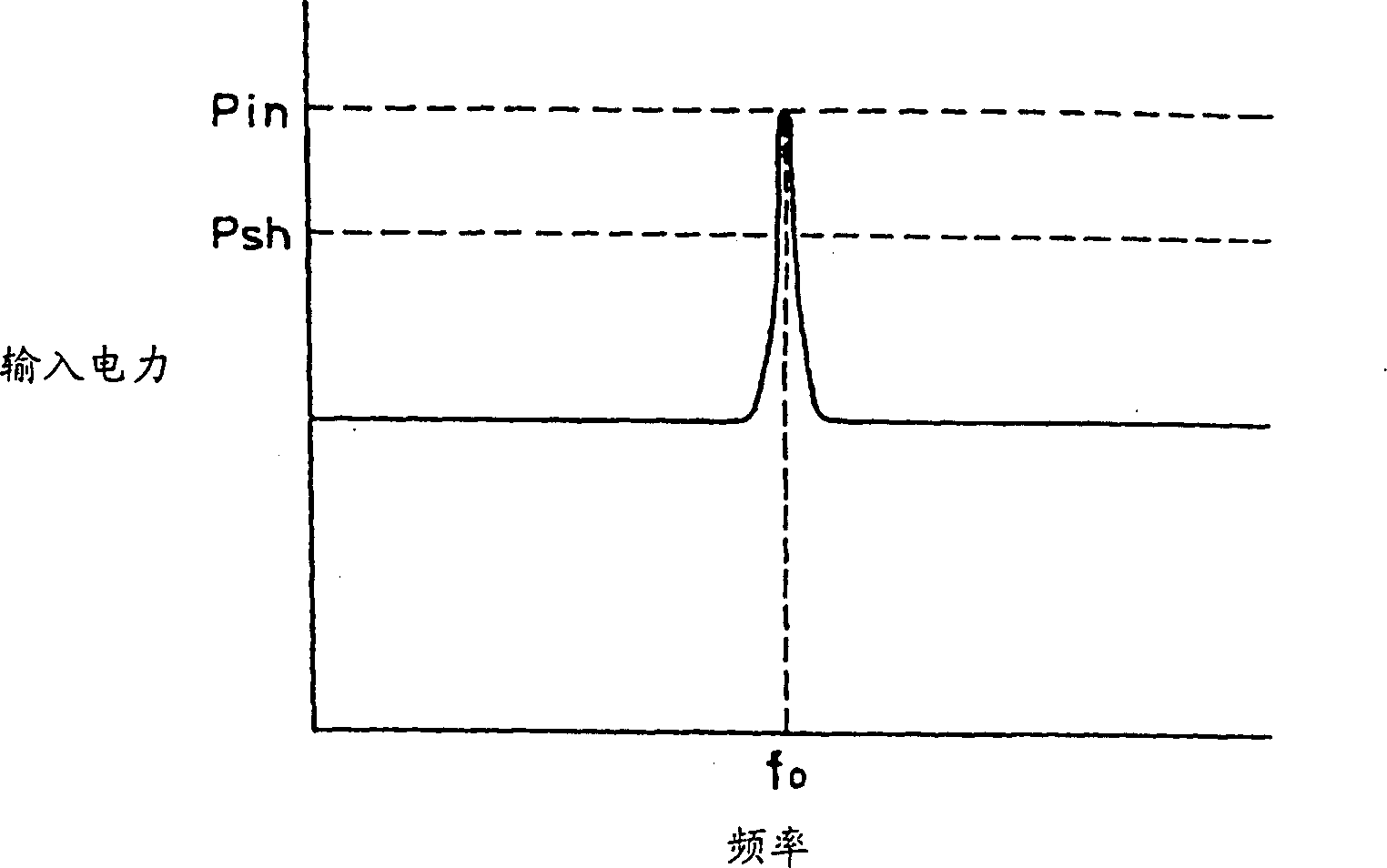

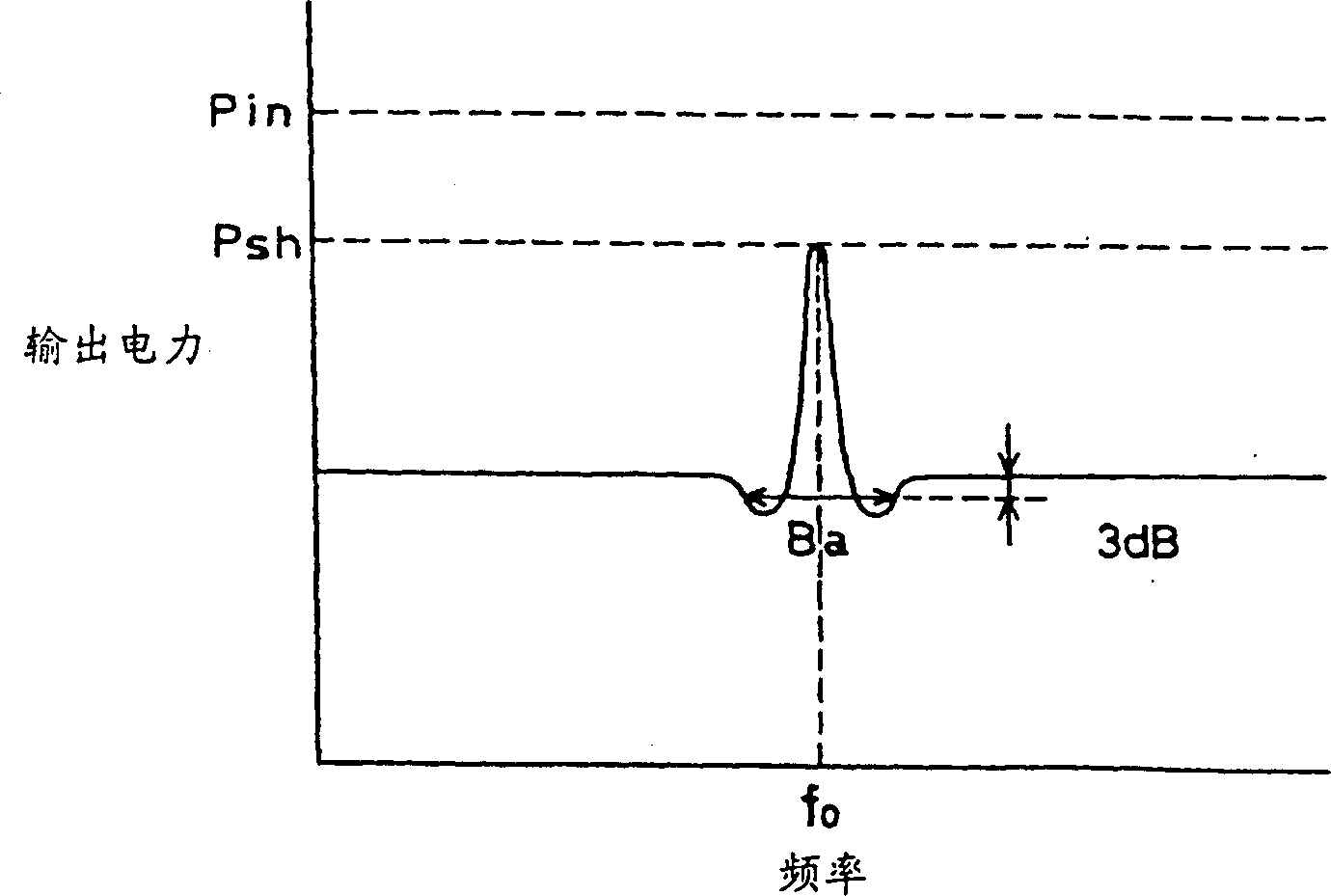

[0038] Two microstrip lines are formed substantially parallel to each other at a specific distance on the single crystal YIG film thus prepared, and the figure 1The magnetostatic wave element shown. In the measurement, Ba was 1.4MHz, wherein the frequency fo of the input signal was set to 1.5GHz, the input electric power Pin was set to -17dBm, and the applied magnetic field H was set to 8000A / m. The value Ba=1.4MHz obtained by this magnetostatic wave element is excellent because it is compatible with image 3 Compared with the value of , it can be seen that this value is only 1 / 5 to 1 / 2 of the value obtained by using lead-containing single crystal YIG film, and the film is made of PbO-B 2 o 3 It is made of raw material melting liquid.

example 2

[0040] With MoO 3 : K 2 O:Y 2 o 3 : Fe 2 o 3 =39.1: 37.5: 16.9: 6.5 mole ratio, so that the solvent component MoO 3 with K 2 O and Fe as components of YIG 2 o 3 with Y 2 o 3 Mix it up, put this mixture into a platinum crucible as a raw material melting liquid, melt at 1200°C for 12 hours, cool to 1100°C, and bring it into contact with a GGG substrate with a diameter of 52mm for 2 hours to form a film on it with a thickness of about 5 μm The composition of single crystal YIG films was analyzed by inductively coupled plasma emission spectrometry. As a result, molybdenum, potassium and platinum were detected as single crystal components Fe 2 o 3 with Y 2 o 3 Other ingredients are listed in Table 2. However, their content is extremely small, not exceeding 40 ppm by weight. Of course, lead was detected in the single crystal film.

[0041] Table 2

Impurity elements

Impurity content

(weight ppm)

40

Lithium...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com