United decomposition technology of tungstite, wolframite alkali decomposition

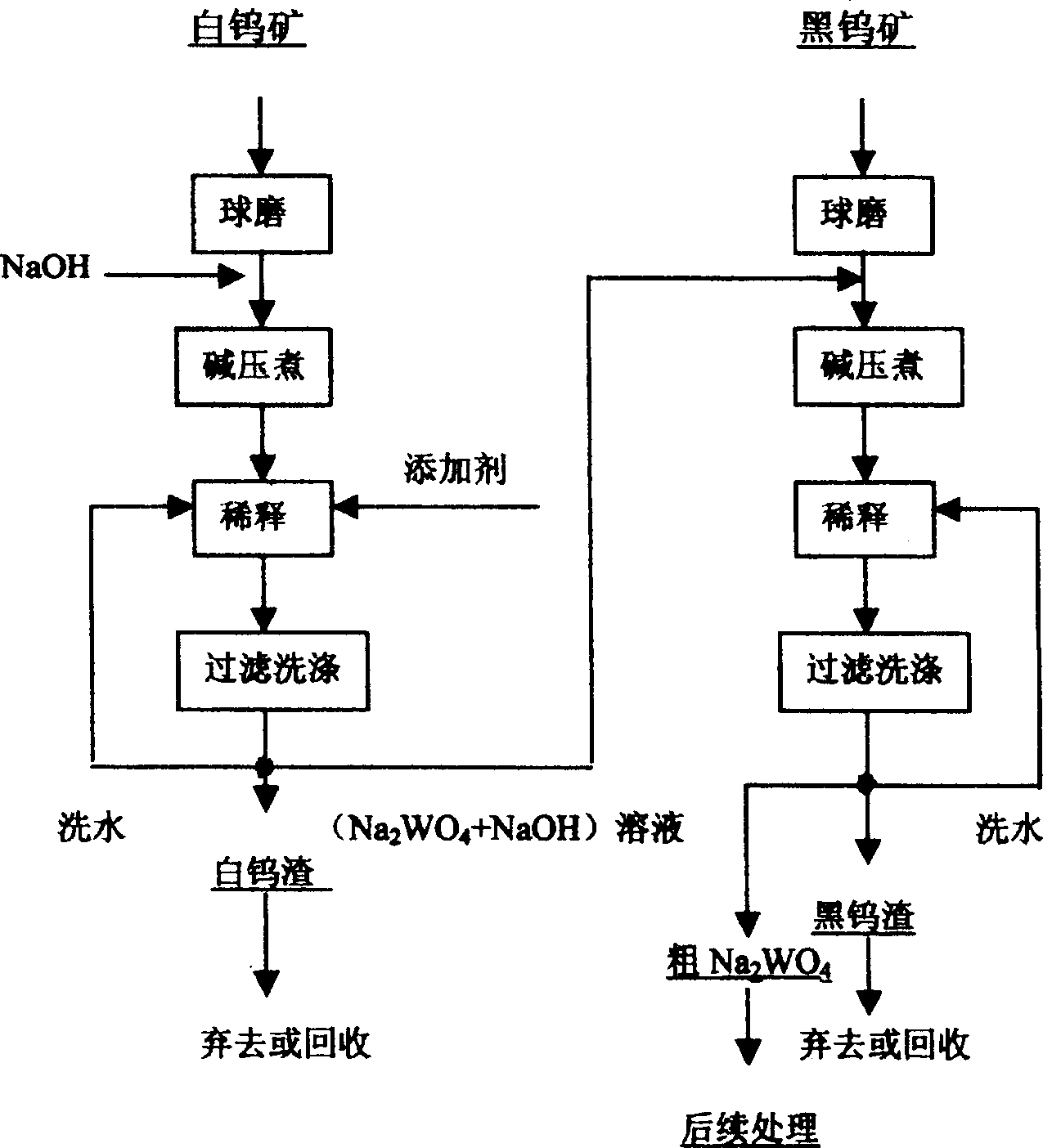

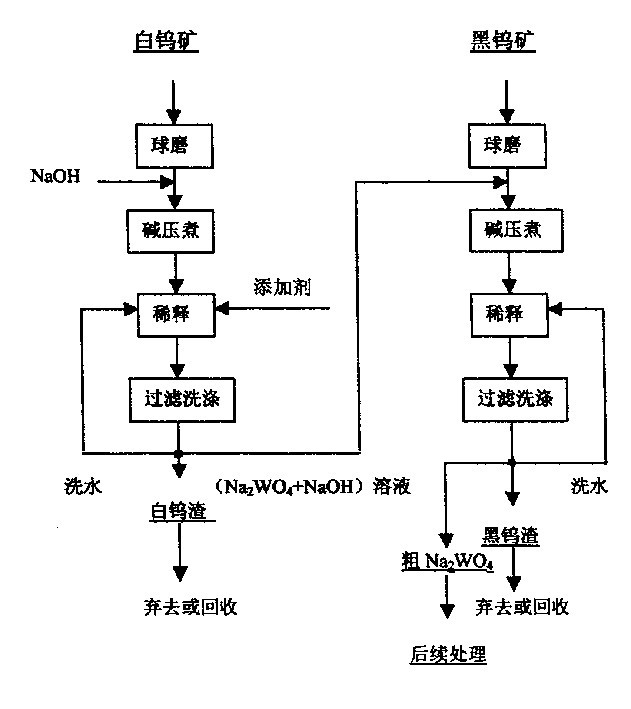

A technology of wolframite and scheelite, which is applied in the field of alkali decomposition to extract tungsten from tungsten mineral raw materials and tungsten metallurgical extraction, can solve the problem of tungsten-alkali separation that has not been fundamentally solved, and has not completely solved the problem of tungsten-alkali separation, which affects the technology industry process and other issues, to achieve the effect of saving tungsten-alkali separation operation, significant economic and social benefits, and reducing the cost of three wastes treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Embodiment 1: certain scheelite concentrate (WO 3 67.%, Ca11.6%) 0.5Kg, ground to a particle size of 97%-0.045mm, and 630ml of liquid caustic soda is added to the autoclave for decomposition, and the amount of NaOH added is based on the amount of WO in the mineral 3 2.7 times the theoretical amount calculated by weight (abbreviated as theoretical amount in the following examples), solid-liquid ratio 1: 1.26, control NaOH initial concentration 500g / L, pressure cooking temperature 190~200°C, pressure 0.90~0.95MPa, time 1.5 hours . After the decomposition is completed, dilute and filter, control the concentration of NaOH to 180g / L, the temperature is 70-80°C, add phosphoric acid, and the amount of addition is PO 4 3- and Ca in scheelite 2+ 1.9% of the theoretically calculated weight of the reaction (abbreviated as theoretical amount in the following examples), after filtering and washing the slag: containing WO in the tungsten slag 3 (total) 0.95%, WO 3 (Soluble) Trac...

example 2

[0019] Example 2: A scheelite concentrate (WO 368.22%, Ca 11.8%, Mo 0.51%) a total of 27Kg, grind to a particle size of 96%-0.045mm, add 3.16 times the theoretical amount of alkali together to decompose in a 50-liter autoclave, the solid-liquid ratio is 1: 1.34, and control the initial NaOH The concentration is 550g / L, the cooking pressure is 0.9MPa, the temperature is 200°C, and the cooking time is 1.5 hours. In addition, 27Kg of scheelite concentrate from the same ore source was ground to a particle size of 98%-0.045mm, and added to another 50-liter autoclave for decomposition together with 3.2 times the theoretical amount of alkali, the solid-liquid ratio was 1:1.5, and the initial concentration of NaOH was controlled to be 510g / L, autoclaving pressure 0.9MPa, temperature 200°C, time 1.5 hours. After the decomposition is completed, dilute and filter respectively, add 1.8% theoretical amount of phosphoric acid each, control NaOH concentration 180g / L, temperature 70-80°C, af...

Embodiment 3

[0020] Embodiment 3: certain scheelite concentrate (WO 3 67.5%, Ca 11.8%, Mo 0.04%) 700Kg, grind to particle size 97%-0.045mm, add 2.0m 3 Decompose in an autoclave, control the initial concentration of NaOH to be 514g / L, cook at a temperature of 195°C, a pressure of 0.9MPa, and a time of 1.5 hours. After the decomposition is completed, dilute and filter, add a theoretical amount of 9.7% phosphoric acid, control the NaOH concentration at 190g / L, and the temperature at 80°C. After filtering and washing the slag: the tungsten slag contains WO 3 (Total) 1.39%, WO 3 (Soluble) 0.1%, WO in solution 3 182.1g / L, NaOH 190g / L, tungsten decomposition rate 99.26%.

[0021] The filtered solution was transferred to the decomposition of wolframite. Wolframite (WO 3 67.8%, Ca1.0%) 2500Kg, ground to a particle size of 93%-0.045mm, and the above filtered 5.5m 3 The solution and the theoretical amount of 0.92 times phosphoric acid were added together for 10m 3 Decompose in an autoclave, t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| decomposition efficiency | aaaaa | aaaaa |

| decomposition efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com