Method and device for producing higher fullerences and nanotubes

A technology of fullerenes and carbon atoms, applied in the field of chemical technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0046] Experiment with the above two methods.

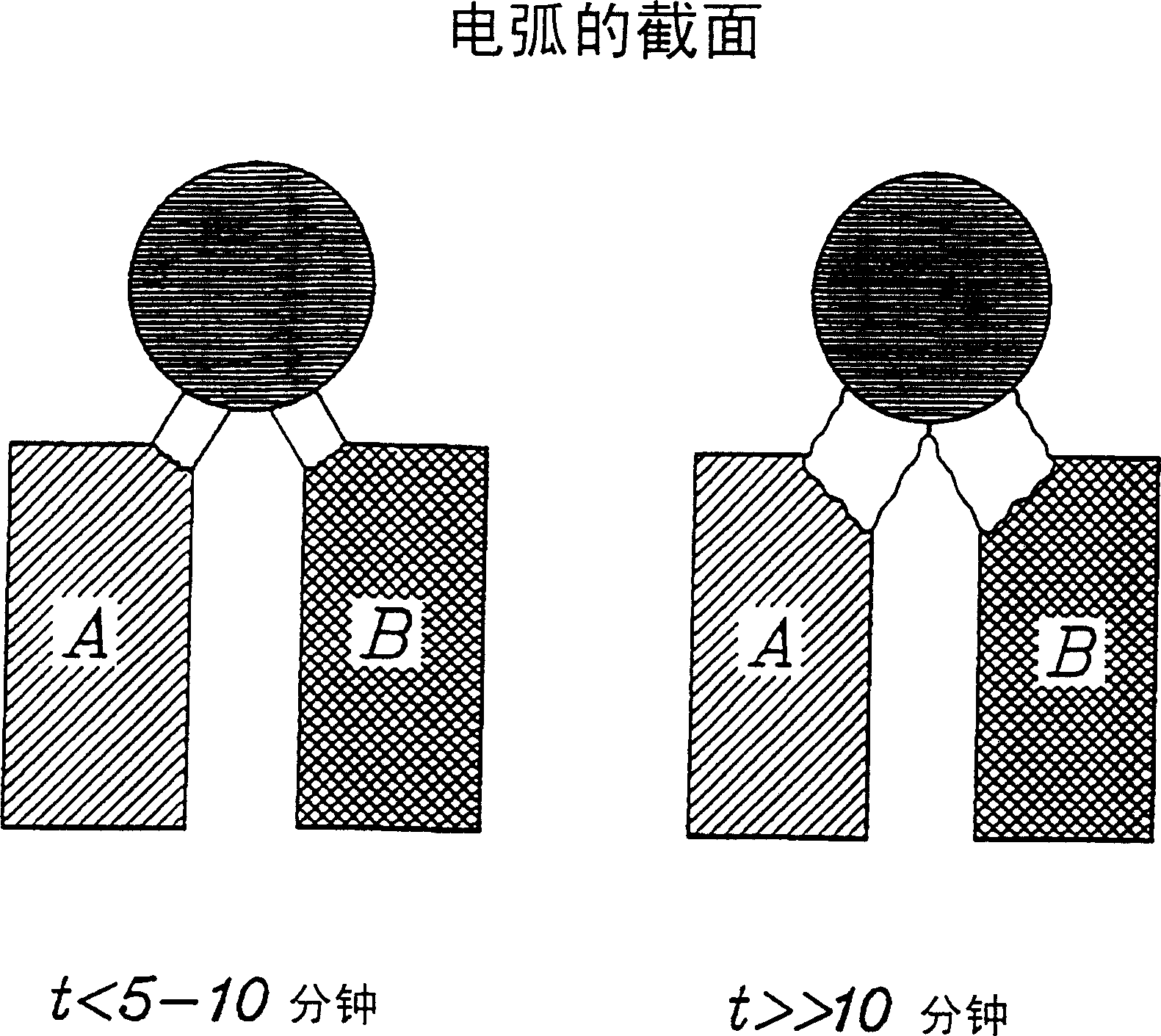

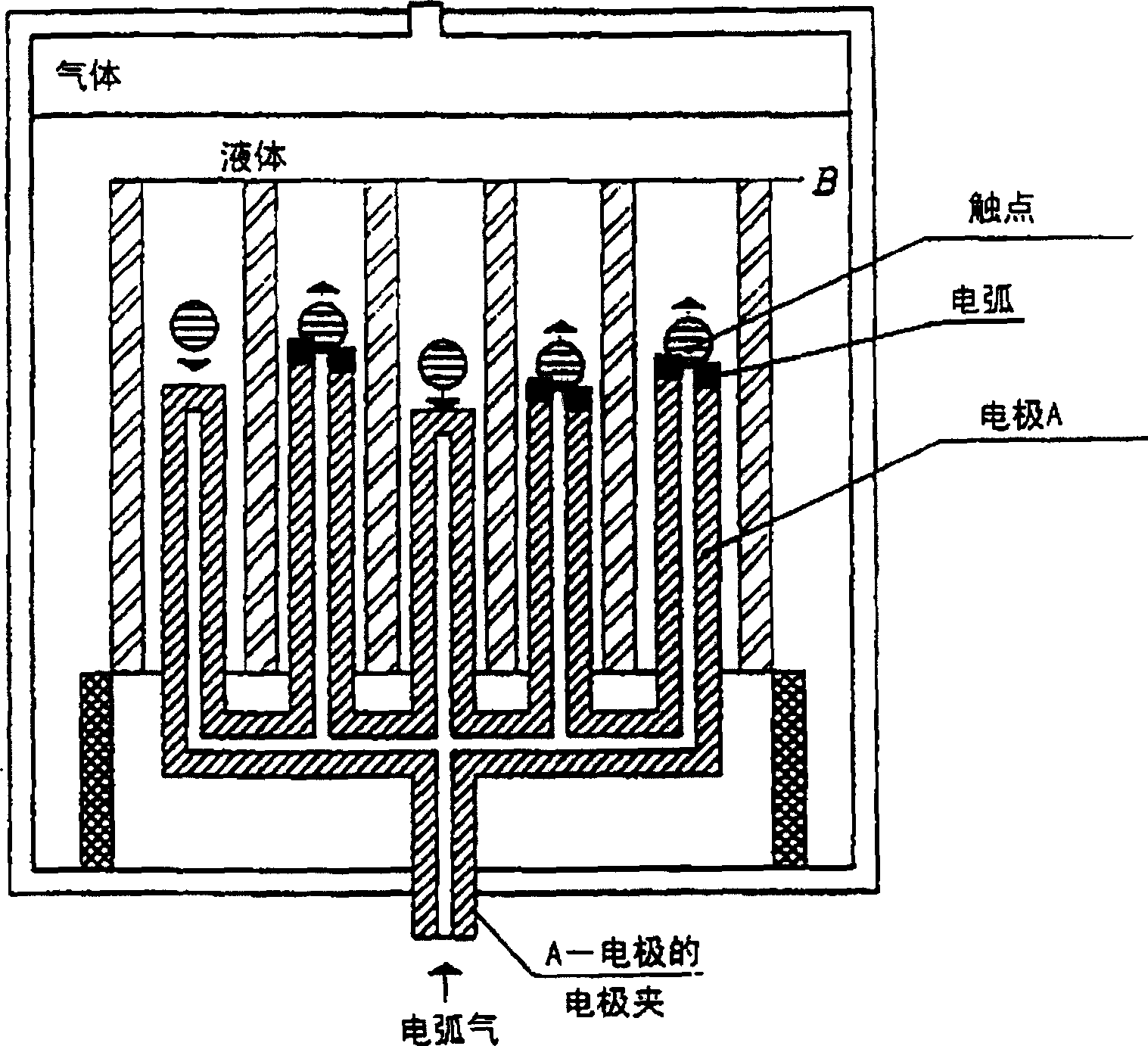

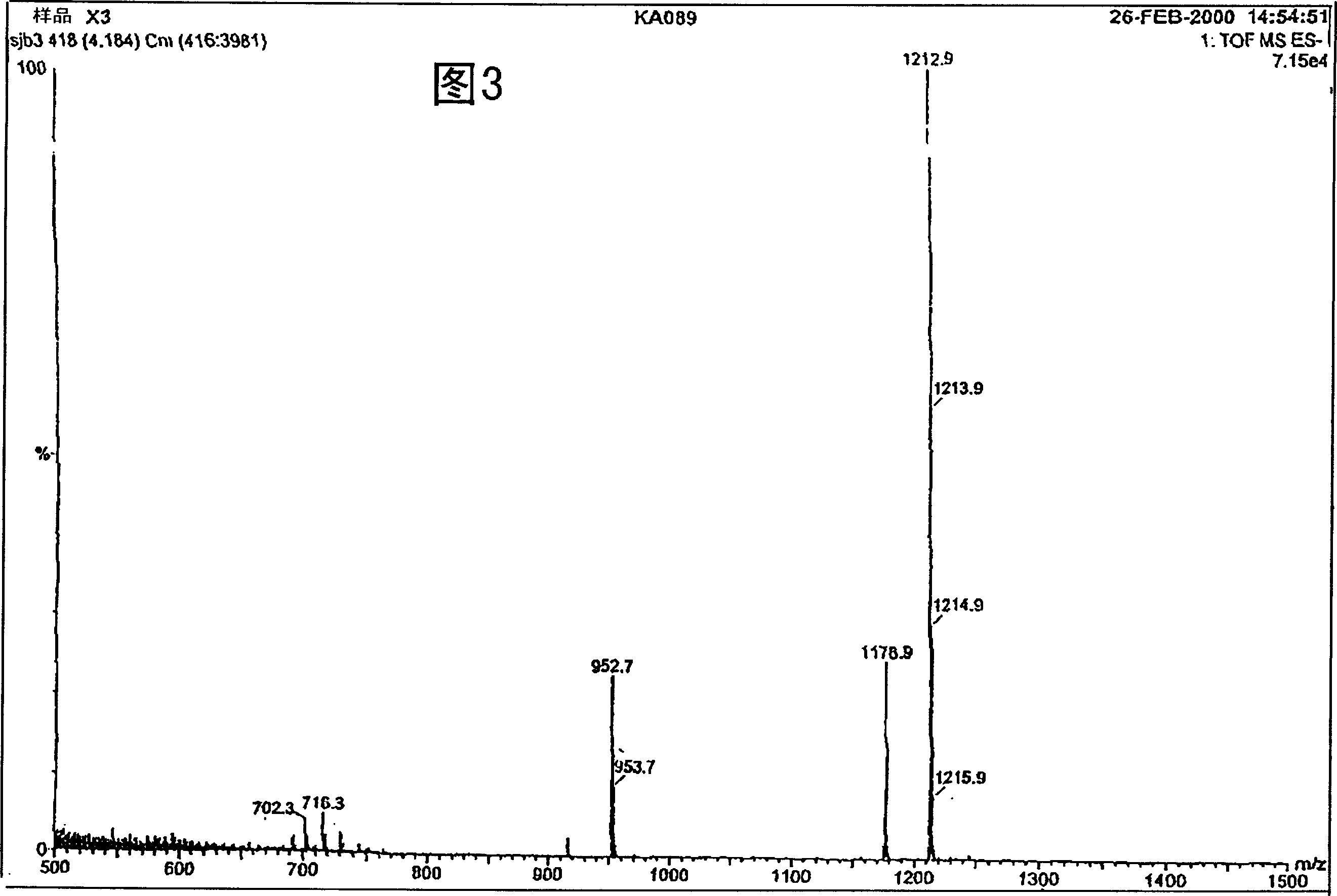

[0047] The equipment is composed as follows: a graphite tube (electrode A) with an outer diameter and an inner diameter of 4 mm and 2 mm respectively, and a length of 50 mm; a spherical graphite contact with a diameter of 12.5 mm; a graphite substrate with a vertical cylindrical channel with a diameter of 13.5 mm (electrode B ). The cylindrical stainless steel housing is filled with liquid (benzene solution based on certain aromatic hydrocarbons like naphthalene, toluene and xylene) up to 50 cm above the contacts. In our tests it was found that such a liquid level provides the maximum time for the arc to function. Pure argon gas is pumped through the graphite tube (electrode A) before and during exposure (removal of oxygen from the device housing and liquid) to create optimal conditions for annealing of carbon clusters to form fullerenes / nanotubes. The arc cross-sectional area is about 3~4mm 2 , the arc current intensity is 10...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com