Position phase type ultra-high-difinition long focal iris

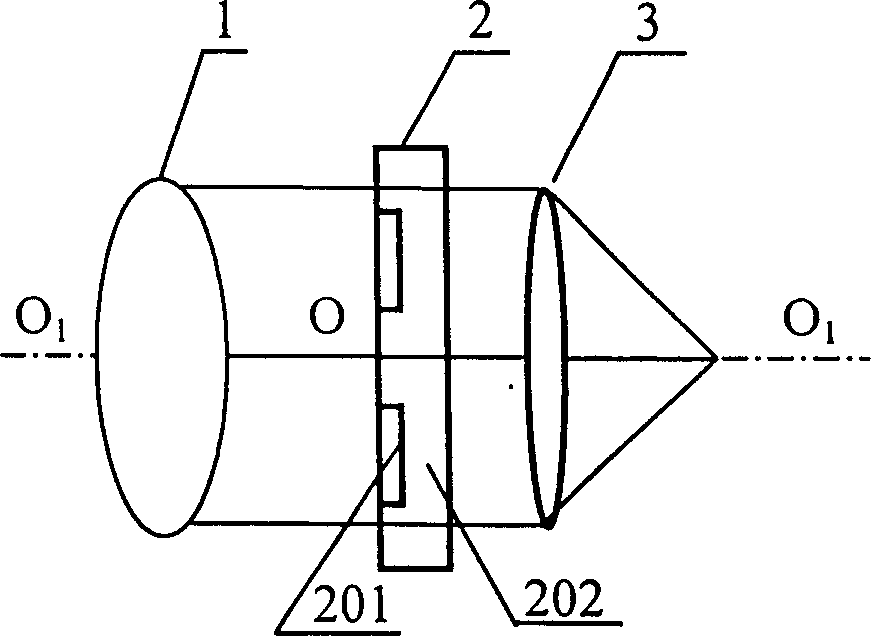

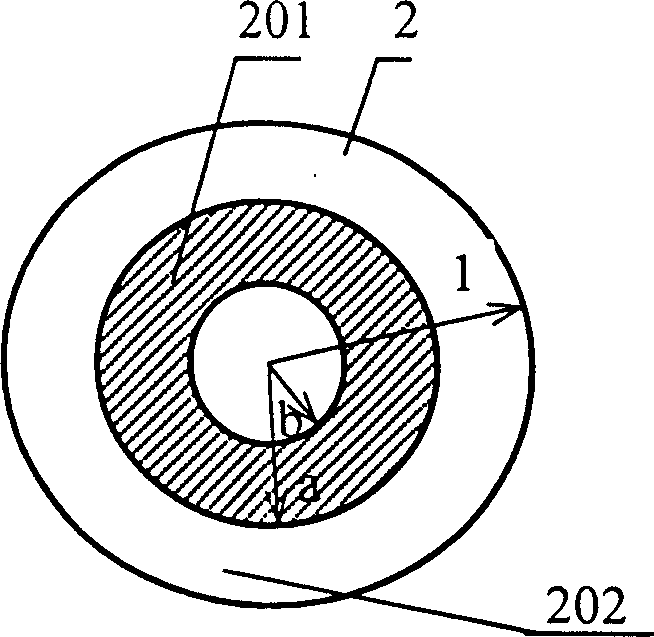

A super-resolution, phase-type technology, applied in apertures, optics, cameras, etc., can solve the problems of low energy utilization, complex aperture amplitude and phase distribution, and difficult production of apertures, achieving wide application prospects and easy mass production. and replication, the effect of high diffraction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

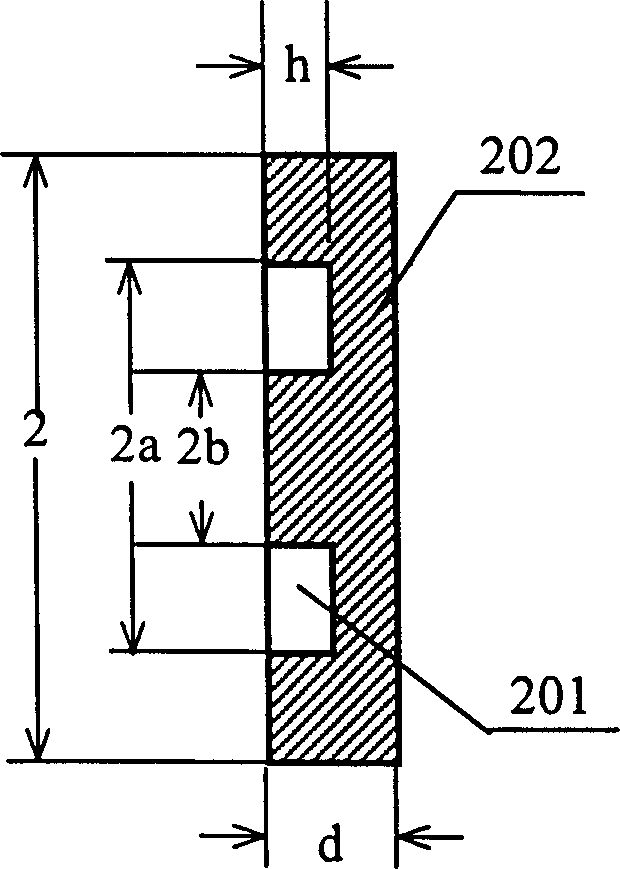

[0018] We optimized the axial light intensity distribution for different b values, and gave a series of b and a values. Different values of b and a correspond to different focal depth extensions. Tables 1 and 2 give a series of b, a, focal depth extension multiples, half-width ratio, side lobes relative to the main spot intensity, Sterby.

[0019] b

a

Depth of focus extension factor t

Half-width ratio

Sterby

Relative intensity of side lobe

0

0

1

1

1

0.01

0

0.4

2.34

0.829

0.449

0.23

0.05

0.41

2.43

0.824

0.434

0.235

0.1

0.42

2.57

0.817

0.410

0.238

0.15

0.45

2.57

0.816

0.396

0.222

0.2

0.48

2.63

0.813

0.369

0.203

[0020] 0.25

0.52

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com