Spherical aluminium oxide carrier material and preparation process thereof

A technology of spherical alumina and carrier materials, applied in the direction of catalyst carriers, chemical instruments and methods, chemical/physical processes, etc., can solve problems that do not involve the magnetic properties of alumina, no alumina carrier materials have been found, and achieve good thermal stability Sex and corrosion resistance, good magnetic properties, cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

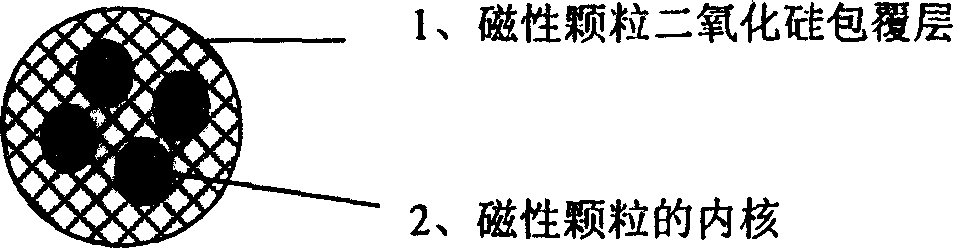

Method used

Image

Examples

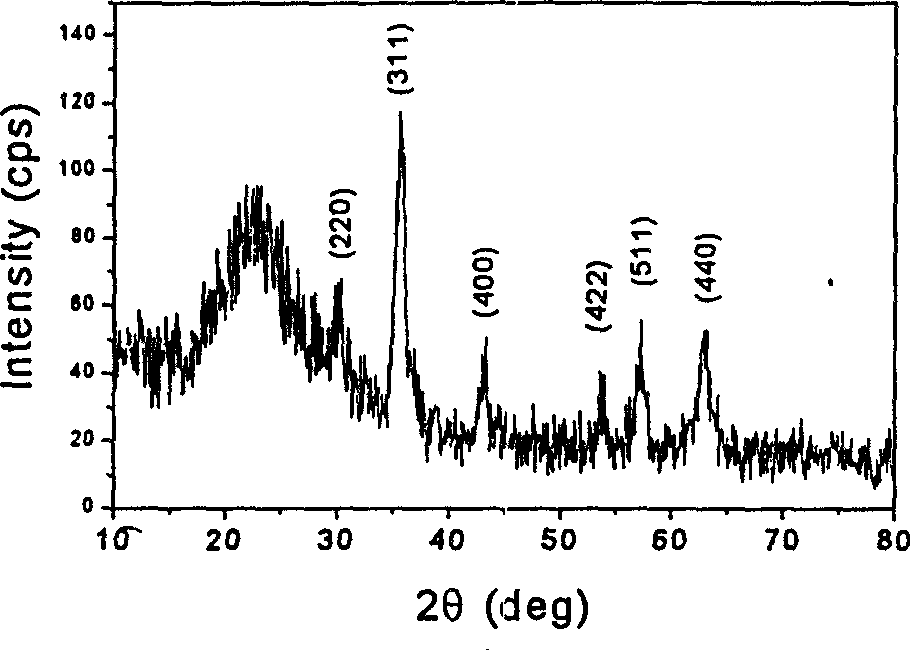

Embodiment 1

[0041] 189g Na 2 SiO 3 ·9H 2 O (Zhejiang Wenzhou Dongsheng Chemical Reagent Factory) was dissolved in 800 mL of distilled water, 3mol / L HCl solution was slowly added dropwise under stirring, the pH value of the solution was adjusted to 13, and it was filtered for use.

[0042] Add 23.4g FeCl to a 2-liter stirred reactor containing 1000mL distilled water 3 ·6H 2 O (Beijing Chaoyang Tonghui Chemical Plant) and 8.6g FeCl 2 ·4H 2 O (Beijing Shuanghuan Chemical Reagent Factory), under the protection of nitrogen, the temperature is increased to 85~90℃, and 30mL of 25% NH is added during high-speed stirring. 3 ·H 2 O solution, after stirring at high speed for 3 min, separate Fe with magnetic separator 3 O 4 Nanoparticle products. The deposited product after cleaning is ultrasonically dispersed in the above pretreated Na 2 SiO 3 The solution is then transferred to a 2 liter stirred reactor, and the temperature is raised to 85°C. Under nitrogen protection and stirring, slowly add HCl solut...

Embodiment 2

[0050] 28.4g Na 2 SiO 3 ·9H 2O (Zhejiang Wenzhou Dongsheng Chemical Reagent Factory) was dissolved in 600 mL of distilled water, 3mol / L HCl solution was slowly added dropwise under stirring, the pH value of the solution was adjusted to 13, and it was filtered for use.

[0051] Add 46.7g FeCl to a 2-liter stirred reactor containing 1000mL distilled water 3 ·6H 2 O (Beijing Chaoyang Tonghui Chemical Plant) and 17.2g FeCl 2 ·4H 2 O (Beijing Shuanghuan Chemical Reagent Factory), under the protection of nitrogen, heat to 85~90℃, add 160mL 6MolL NaOH solution during high-speed stirring, and after high-speed stirring for 3min, separate Fe with magnetic separator 3 O 4 Nanoparticle products. The deposited product after cleaning is ultrasonically dispersed in the above pretreated Na 2 SiO 3 The solution is then transferred to a 2 liter stirred reactor, the temperature is raised to 85°C, and under the protection of nitrogen and stirring, the HCl solution with a concentration of about 1.5 mo...

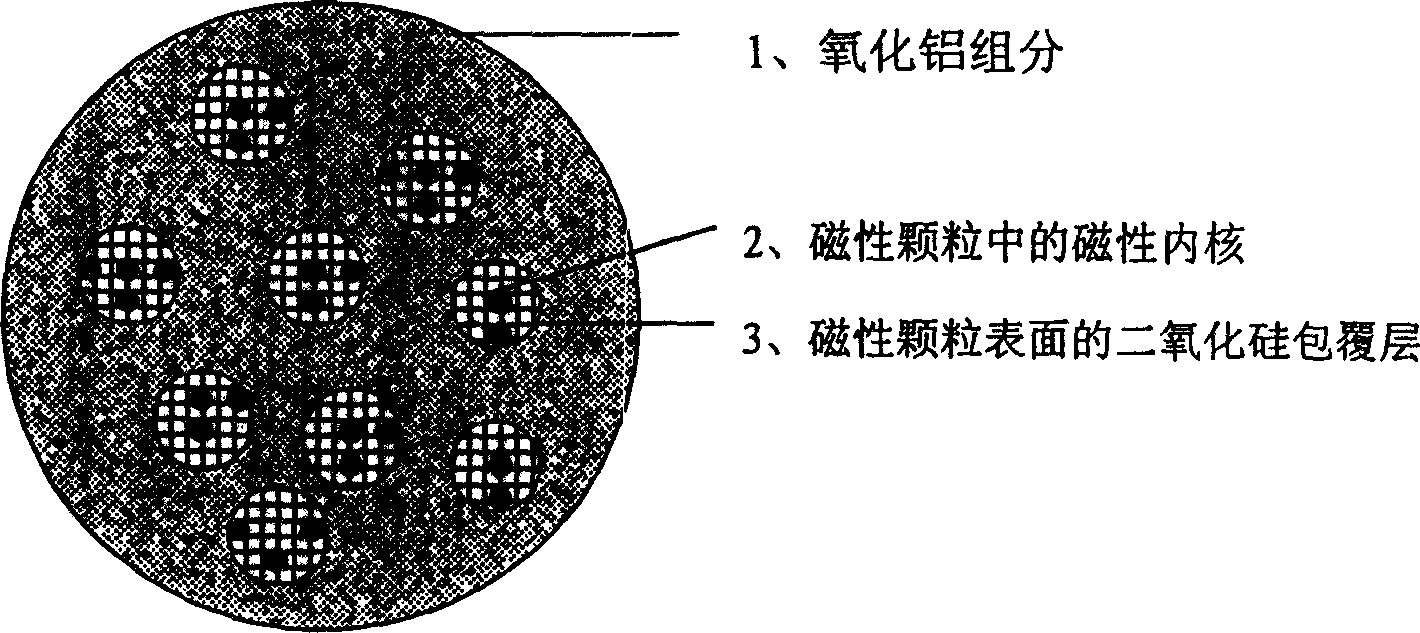

Embodiment 3

[0057] The above AL1 magnetic spherical Al(OH) 3 The product was put into a 1L autoclave containing 0.7L sulfonated kerosene medium, and subjected to hydrothermal treatment at 140°C under nitrogen protection for 3 hours. After cleaning and degreasing the product, it was then placed in dilute ammonia water with pH=11 (measured at room temperature) at 80°C. Aging for 6 hours (removing some of the impurities), after drying at 60°C, magnetic spherical Al(OH) with a boehmite structure (α-AlOOH) can be obtained 3 The product is sintered in an air atmosphere at 580°C for 2 hours to obtain about 60 g of γ-Fe 2 O 3 Spherical γ-Al with magnetic core 2 O 3 Carrier. The content ratio (weight ratio) of each component in the carrier material is: γ-Fe 2 O 3 : SiO 2 : Al 2 O 3 =30:9:61 (in addition, the carrier also contains part of water). This carrier has superparamagnetic characteristics.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com