Contact chamber for catalytic cracking of oil

A technology of catalytic cracking oil and contact chamber, which is applied in the direction of catalytic cracking, cracking, petroleum industry, etc., can solve the problem of high coking coefficient of residual carbon conversion, catalyst back-mixing and residence time aggravated secondary reaction and metal dehydrogenation reaction, product Selective deterioration and other problems, to achieve the effect of increasing the contact probability of agent oil, overcoming low catalyst density, and preventing severe coking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

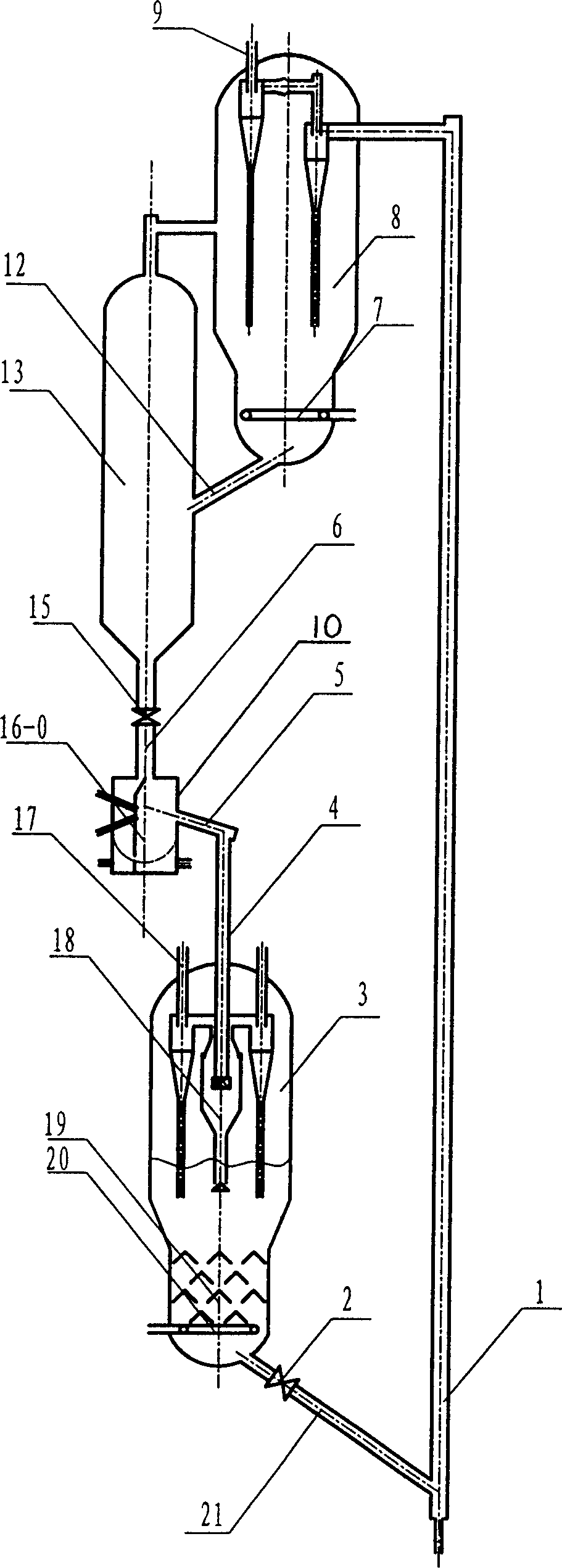

[0043] This example illustrates: the application of the oil agent contact chamber provided by the present invention on a medium-sized catalytic cracking unit.

[0044] According to the structural characteristics of the oil agent contact chamber provided by the present invention, in such as figure 1 Experiments were carried out on the catalytic cracking medium-sized unit shown. The properties of the raw oil used in the test are shown in Table 1, and the properties of the catalyst used are shown in Table 2. The catalyst is industrially produced by the Catalyst Factory of Lanzhou Oil Refining and Chemical Company, and the trade name is LV-23.

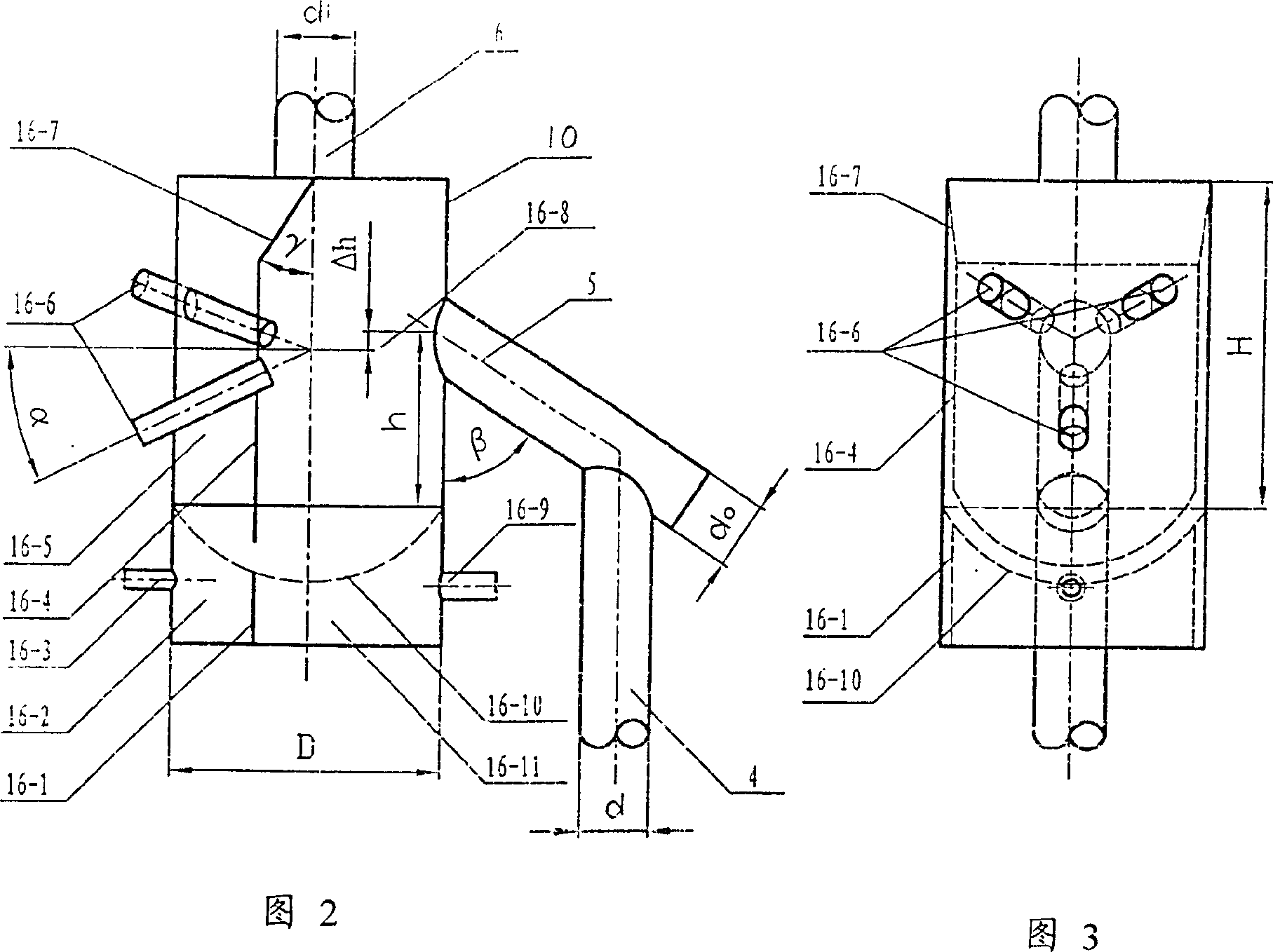

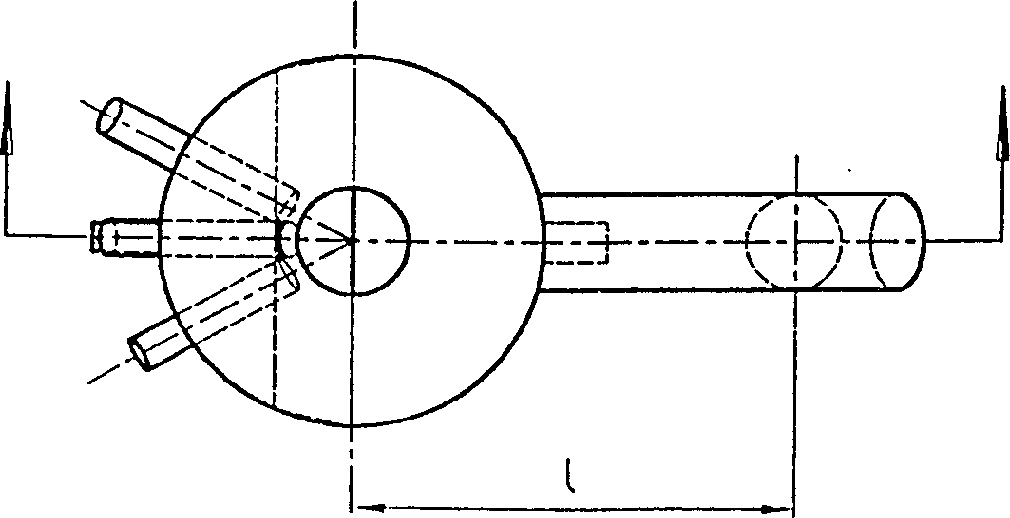

[0045] The main structural dimensions of the oil agent contact chamber in the medium-sized device used in the test are as follows: the diameter of the downcomer reactor d=20mm, the diameter of the oil agent contact chamber D=70mm, and its height H=100mm. The vertical partition divides the agent-oil contact chamber into two parts whose cro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com