Process for preparing crystal film for components to emit blue light

A thin film and crystal technology, applied in the field of crystal thin film preparation, can solve the problem of not having luminescent properties, and achieve the effects of good crystal quality, good repeatability and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The implementation method of the present invention will be further described below in combination with specific examples.

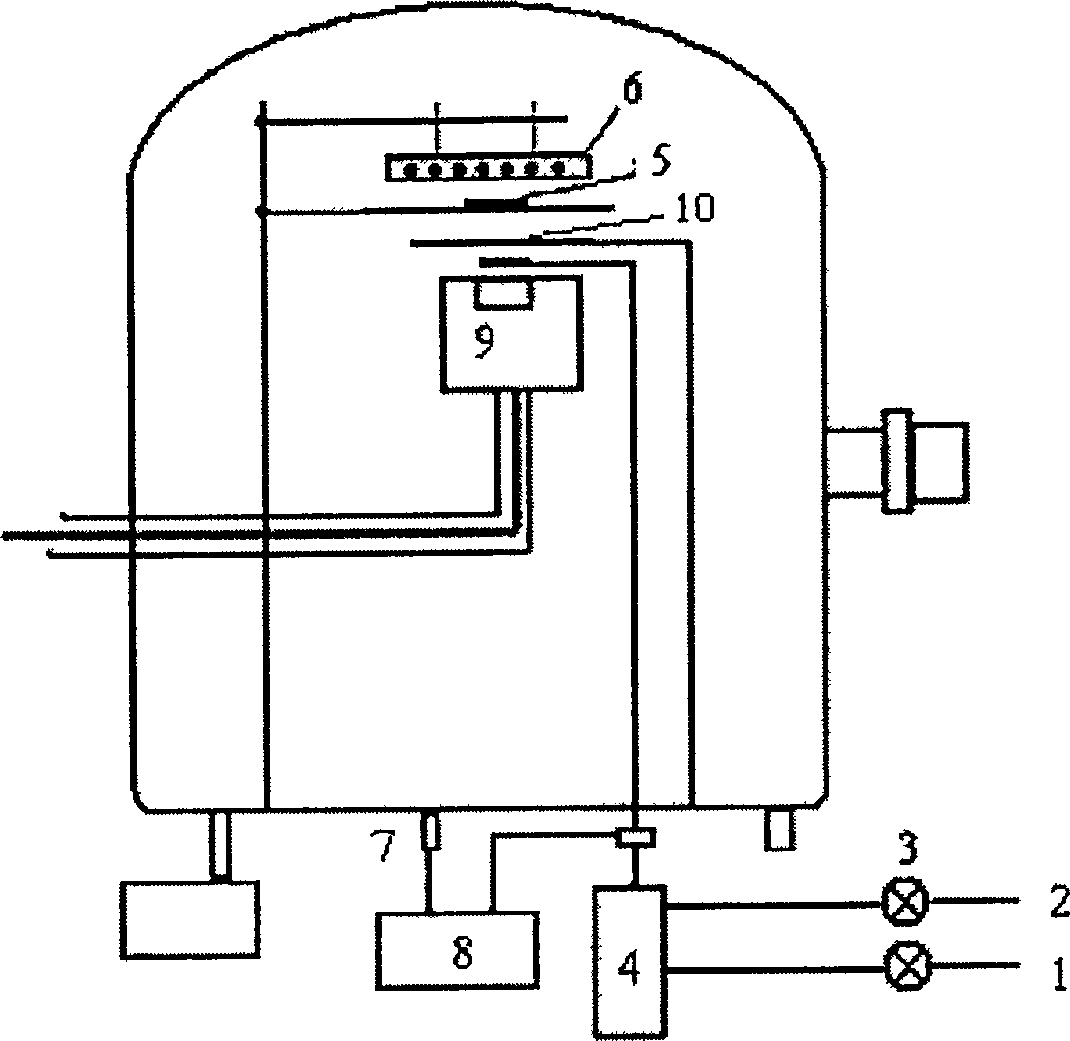

[0014] Put the substrate on the sample holder 5 of the reaction chamber after surface cleaning, and place the substrate facing down to effectively prevent the contamination of the substrate by granular impurities. The vacuum degree of the reaction chamber is pumped to 10 -3 Pa; use the heater to heat the substrate, and the substrate temperature is controlled at 450 ° C; the sputtering gas is high-purity Ar (99.99% or more) and high-purity O 2 (more than 99.99%), the two-way gas enters the buffer chamber 4 through the intake pipes 1 and 2, and is introduced into the vacuum chamber after being fully mixed in the buffer chamber. The pressure in the vacuum chamber is controlled by the automatic pressure controller 8, and the pressure is about 4Pa. The ratio of argon to oxygen is controlled at Ar:O 2 =1:4, this can be realized by the flow meter 3; with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com