A kind of cerium, terbium co-doped borate fluorescent powder and preparation method thereof

A phosphor, borate technology, applied in chemical instruments and methods, luminescent materials, semiconductor devices, etc., can solve the problems of low luminous efficiency, poor thermal stability, difficult synthesis process conditions, etc., achieve good thermal stability, improve Thermal stability, the effect of extending the excitation range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0038] The specific steps of the preparation method of the borate fluorescent powder co-doped with cerium and terbium provided by the invention are as follows:

[0039] (1) According to the chemical formula Ba 2-n Sr n Y 5-x-y-m L m Ce x Tb y B 5 o 17 The stoichiometric ratio of each element in the 2+ compounds containing Y 3+ Compounds containing Ce 3+ Compounds containing Tb 3+ compounds containing B 3+ Compounds containing Sr 2+ Compounds containing La 3+ Compounds containing Gd 3+ Compounds containing Lu 3+ Compounds, and compounds containing Sc 3+ compound, ground in an agate mortar and mixed well to obtain a mixture;

[0040] (2) The above mixture is pre-sintered at 350°C to 600°C in a reducing gas atmosphere or in air, and the sintering time is 1 to 6 hours; it is heated to a sintering temperature of 1000°C to 1300°C in a reducing gas atmosphere, and the sintering time is After 2-24 hours, the sintered product is naturally cooled, and then ground to obt...

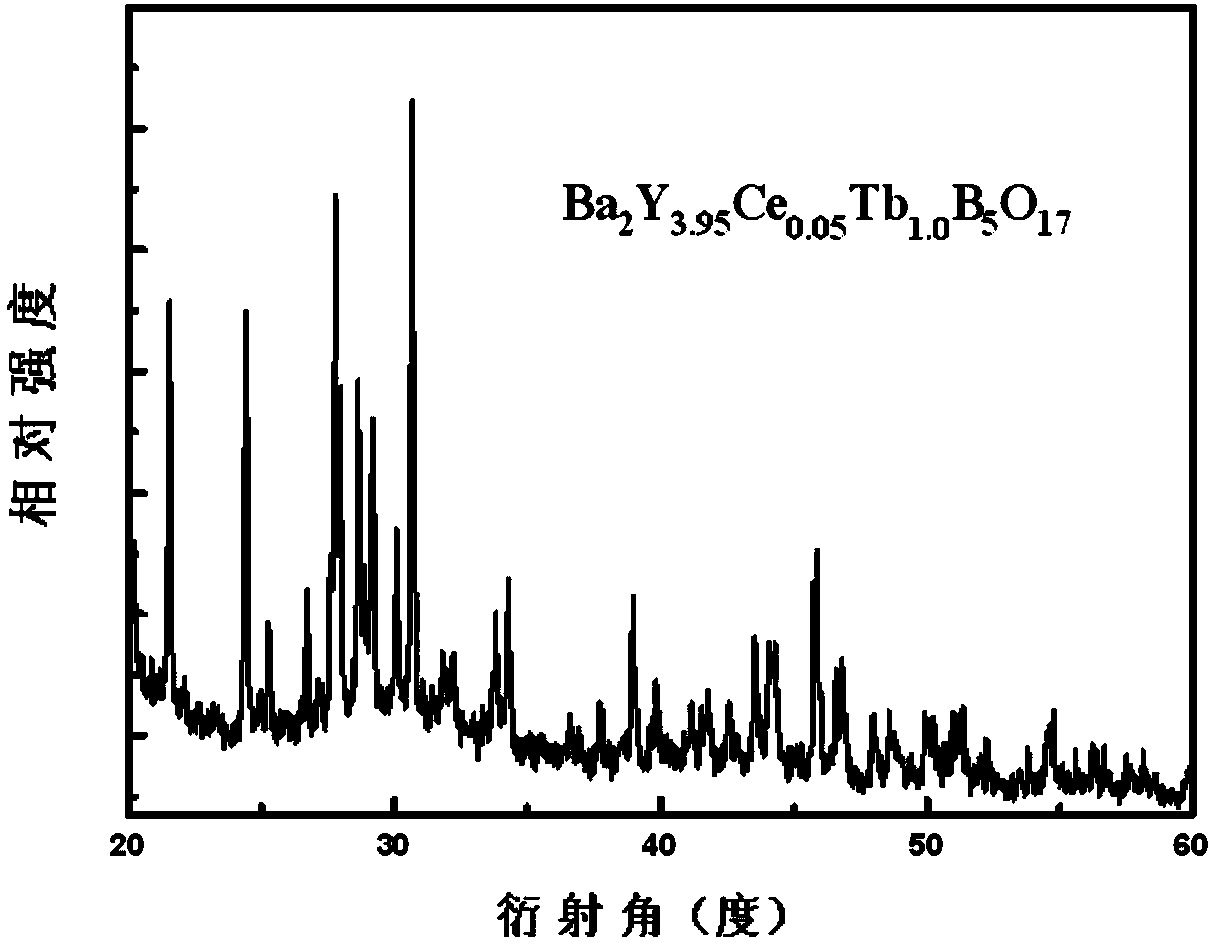

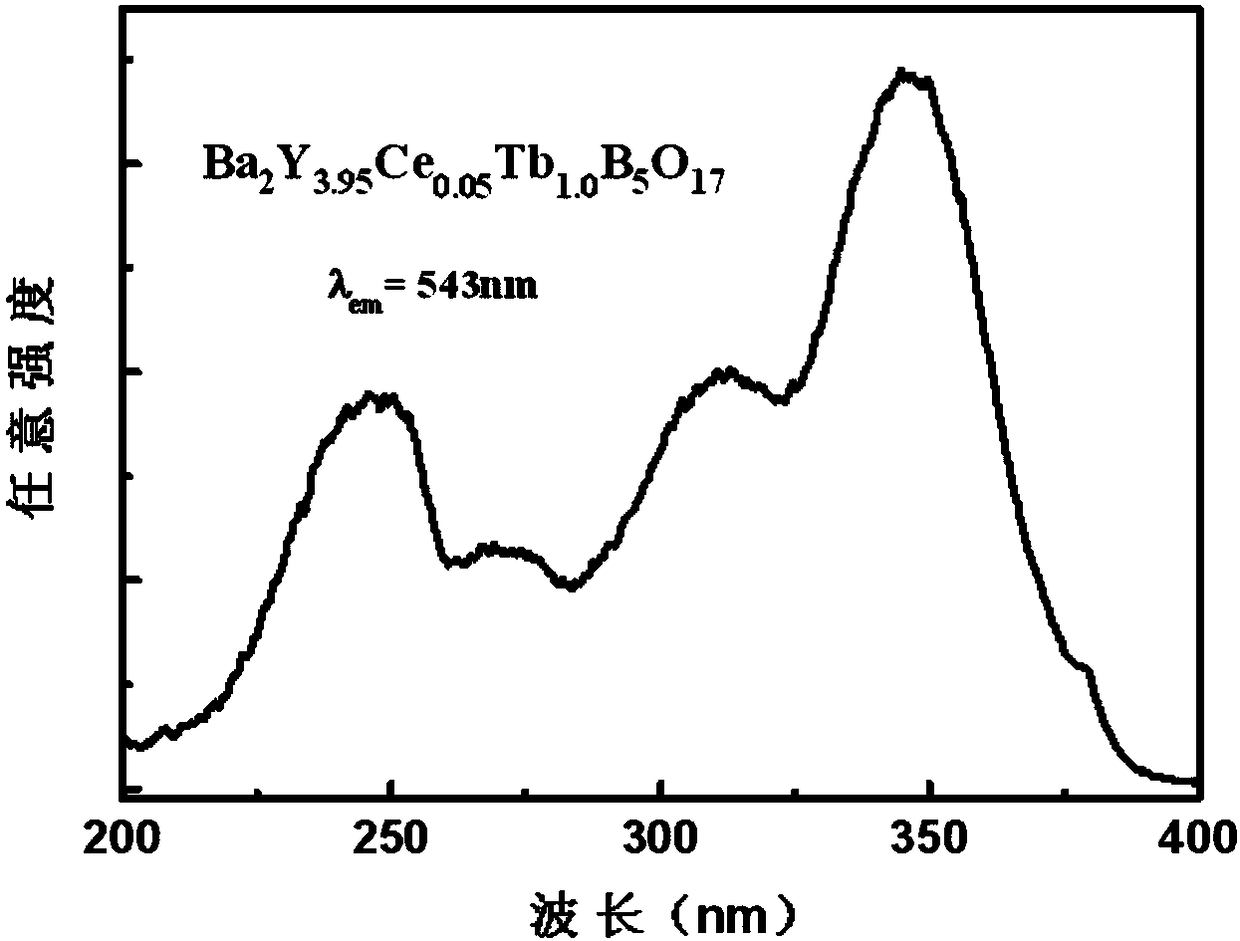

Embodiment 1

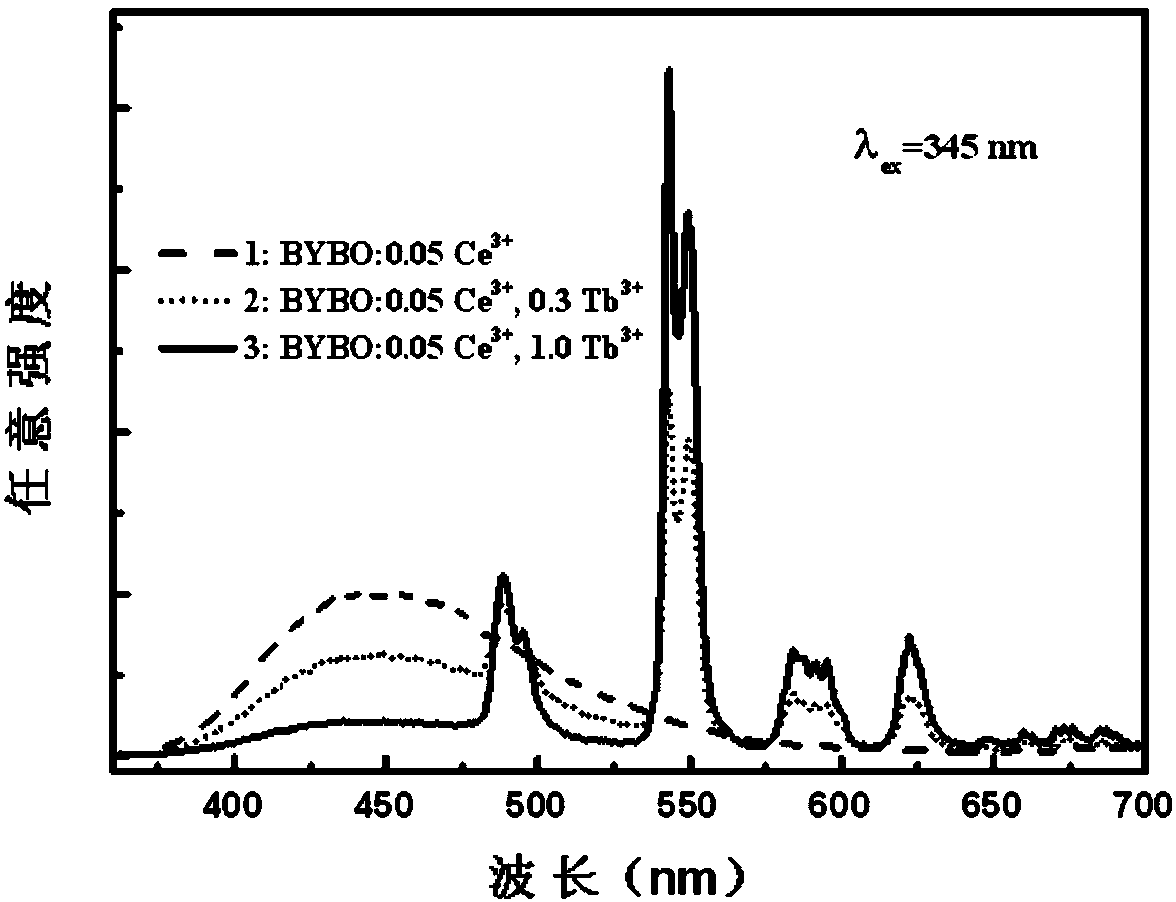

[0046] Embodiment 1 (comparative example)

[0047] Ba 2 Y 4.95 Ce 0.05 B 5 o 17 preparation of

[0048] Weigh BaCO according to stoichiometric ratio 3 : 0.3947 g, H 3 BO 3 : 0.3092 g, Y 2 o 3 : 0.5589 g, CeO 2 : 0.0086 g. Grind and mix evenly in an agate mortar, put it into a corundum crucible, cover it, place it in a high-temperature furnace, and carry out pre-sintering at 450°C under a reducing atmosphere or in air, and the sintering time is 4 hours. h 2 Under reducing atmosphere, heat up to 1200°C and sinter for 10 hours. After natural cooling, properly grind to obtain phosphor powder Ba 2 Y 4.95 Ce 0.05 B 5 o 17 . Its crystal structure is similar to embodiment 4, and the excitation spectrum of the present embodiment is shown in the attached Figure 4 (a), with image 3 Curve 1 is the emission spectrum of the present embodiment, with Figure 5 Data point 1 is the chromaticity coordinate of this example.

Embodiment 2

[0050] Ba 2 Y 4.65 Ce 0.05 Tb 0.3 B 5 o 17 preparation of

[0051] Weigh BaCO according to stoichiometric ratio 3 : 0.3947 g, H 3 BO 3 : 0.3092 g, Y 2 o 3 : 0.5250 g, CeO 2 : 0.0086 g, Tb 4 o 7 : 0.0561 g. Grind and mix evenly in an agate mortar, put it into a corundum crucible, cover it, place it in a high-temperature furnace, and carry out pre-sintering at 450°C under a reducing atmosphere or in air, and the sintering time is 4 hours. h 2 Under reducing atmosphere, heat up to 1200°C and sinter for 10 hours. After natural cooling, properly grind to obtain phosphor powder Ba 2 Y 4.65 Ce 0.05 Tb 0.3 B 5 o 17 . Its crystal structure, excitation spectrum are similar to embodiment 4, appended image 3 Curve 2 is the emission spectrum of the present embodiment, with Figure 5 Data point 2 is the chromaticity coordinate of this example.

PUM

| Property | Measurement | Unit |

|---|---|---|

| internal quantum efficiency | aaaaa | aaaaa |

| external quantum efficiency | aaaaa | aaaaa |

| internal quantum efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com