Magnetic component and magnetic head and magnetic memory using this magnetic component

A magnetic element and strong magnetic technology, applied in static memory, digital memory information, manufacturing flux-sensitive magnetic heads, etc., can solve the problems of small saturation magnetic field, difficulty in making components with stable characteristics, and reduction of MR change rate, and achieve The effect of small resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

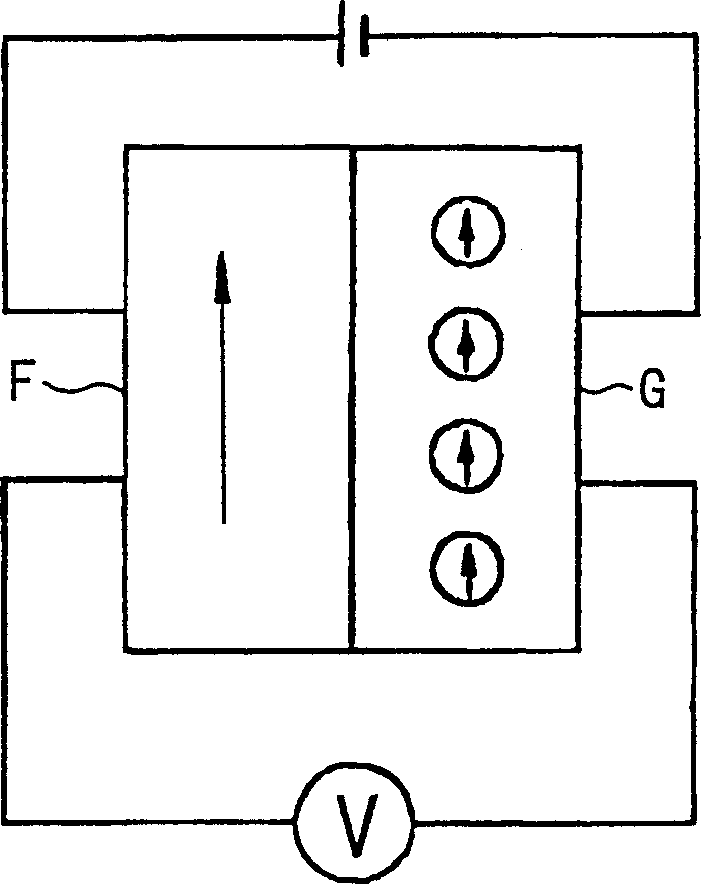

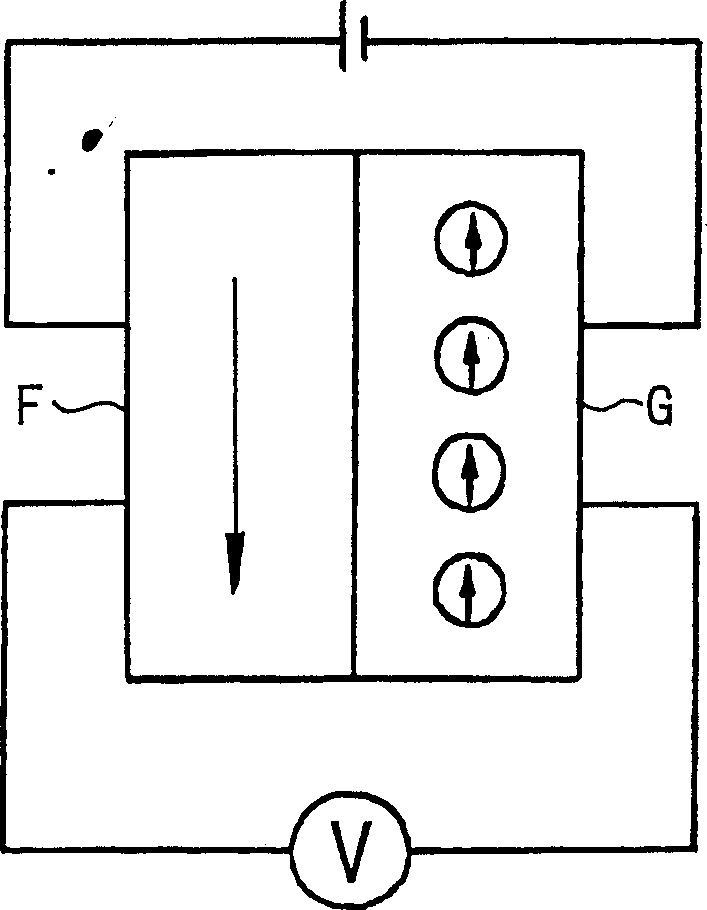

[0141] Fabricated using high frequency sputtering method with Figure 12 and Figure 13 The structure shown is the strong magnetic tunnel conjunctiva. In this ferromagnetic tunnel conjunctiva the magnetic film acts as a tunnel barrier as particulates. That is, firstly on the glass substrate 2, a replacement is formed as shown in Figure 12 and Figure 13 The shown ferromagnetic film 4a is a rectangular Cr film with a length of 10 mm and a width of 0.5 mm as the lower electrode. A particulate magnetic film 3 is formed thereon to cover a part of the Cr film, and then a ferromagnetic film 4 having the same shape as the Cr film is formed thereon so as to be perpendicular to the Cr film. Then, an Au film was formed as an upper electrode, a voltage was applied between it and the lower electrode, and the magnetoresistance effect was measured.

[0142] The manufacturing method of the granular magnetic film 3 can be as follows: Co80Pt20 alloy and SiO2 are used as pole targets, under t...

Embodiment 2

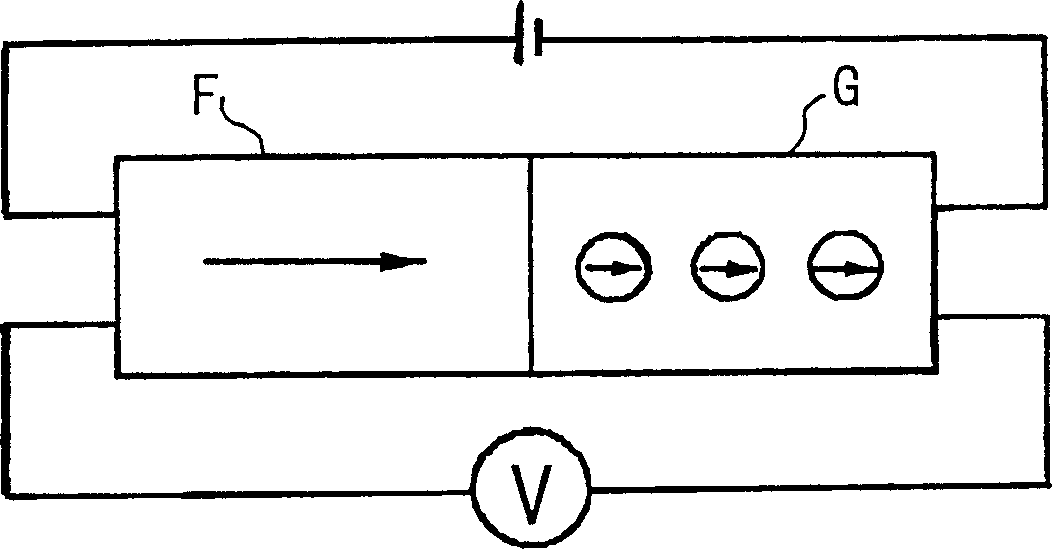

[0149] Produced by high frequency sputtering Figure 18An end-edge junction-type ferromagnetic tunnel junction membrane is shown. That is, at first on the glass substrate 2, according to the same conditions as the first embodiment, a replacement such as Figure 18 The shown lower ferromagnetic film 4 is a Cr film with a length of 10 mm, a width of 0.5 mm, and a thickness of 20 nm. An AlN insulating layer 23 is formed thereon. Subsequently, the ion beam is irradiated from an oblique direction to the end face of the laminated film composed of the Cr film and the AlN insulating layer 23 by using a concentrated ion beam to process the inclined laminated film end face. Then, in a manner covering this inclined end face, a particle magnetic film 3 with Co80Pt20 alloy particles dispersed in the SiOx matrix and a thickness of 10 nanometers is formed, and a ferromagnetic film 4 with a thickness of 20 nanometers is formed thereon. Co90Fe10 alloy film.

[0150] In the edge-bonded ferr...

Embodiment 3

[0152] Using high frequency sputtering method to produce such as Figure 7 laminated film shown. That is, firstly, on the glass substrate 2, a 20nm-thick Fe film is formed as the ferromagnetic film 4 under the conditions of an Ar gas pressure of 0.3 Pa and a substrate bias of 400 W, using Fe as the pole target. On it, ((La0.7Sr0.3)MnO3)80(Bi2O3)20 is used as the pole target, and sputtering is carried out under the above conditions to produce (La0.7Sr0.3)MnO3 with strong magnetism dispersed in Bi2O3 A granular film (with a film thickness of 10 nm) was used as the particulate magnetic film 3 . Then, on this granular magnetic film 3, an FeMn antiferromagnetic film 10 having a film thickness of 20 nm was formed.

[0153] An Au electrode was formed by sputtering on the FeMn antiferromagnetic film 10, a voltage was applied between it and the Fe film, and the magnetoresistance effect was measured. Its magnetoresistance change rate was 33%, and its magnetization reversal magnetic f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Film thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com