Nervous duct and membrane with fixed nerve regeneration promoting agent with surface modified by plasma and their preparations

A nerve regeneration and plasma technology, applied in catheters, coatings, etc., can solve problems affecting nerve growth promoters, nerve growth promoter diffusion, adverse reactions of the body, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] The preparation of embodiment 1 lysine plasma surface modification coating film

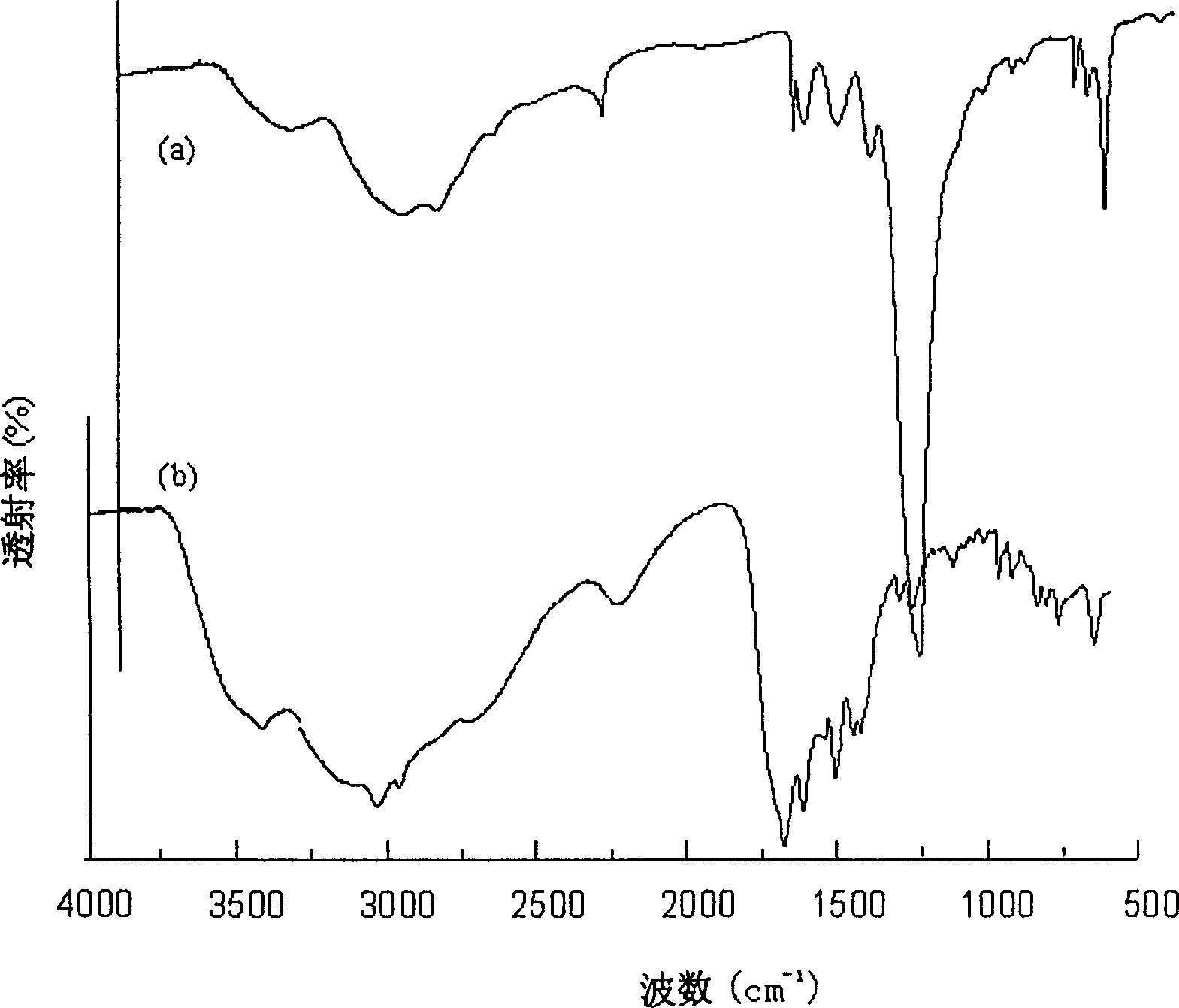

[0035] PGLA with a molecular weight of 200,000 is melted on the glass sheet and cooled into a uniform transparent film. Put it into a 13.56MHz glass plasma reactor with a diameter of 10cm and a length of 55cm. The electrodes are capacitively coupled. Vacuum to vacuum degree 3.5×10 -2 pa, pass through the prepared lysine aqueous solution with a concentration of 30%, and introduce the reactor through argon gas. Adjust the flow meter to control the gas flow to 100sccm, the vacuum degree to 50Pa, adjust the pulse ratio to 80%, the "on" time interval to 3ms, the power to 40w, turn on the power supply and discharge polymerization for 3hrs to obtain polylysine-coated PGLA film, lysine Infrared spectra of acid coatings such as figure 1 As shown, the amino acid amide I (1620cm -1 at C=O stretching vibration peak), amide II (1520cm -1 N-H deformation vibration peak), amide III gene (1351cm -1 ...

Embodiment 2

[0036] Embodiment 2 Preparation of Vinylacetic Acid Plasma Surface Modification Coating Film

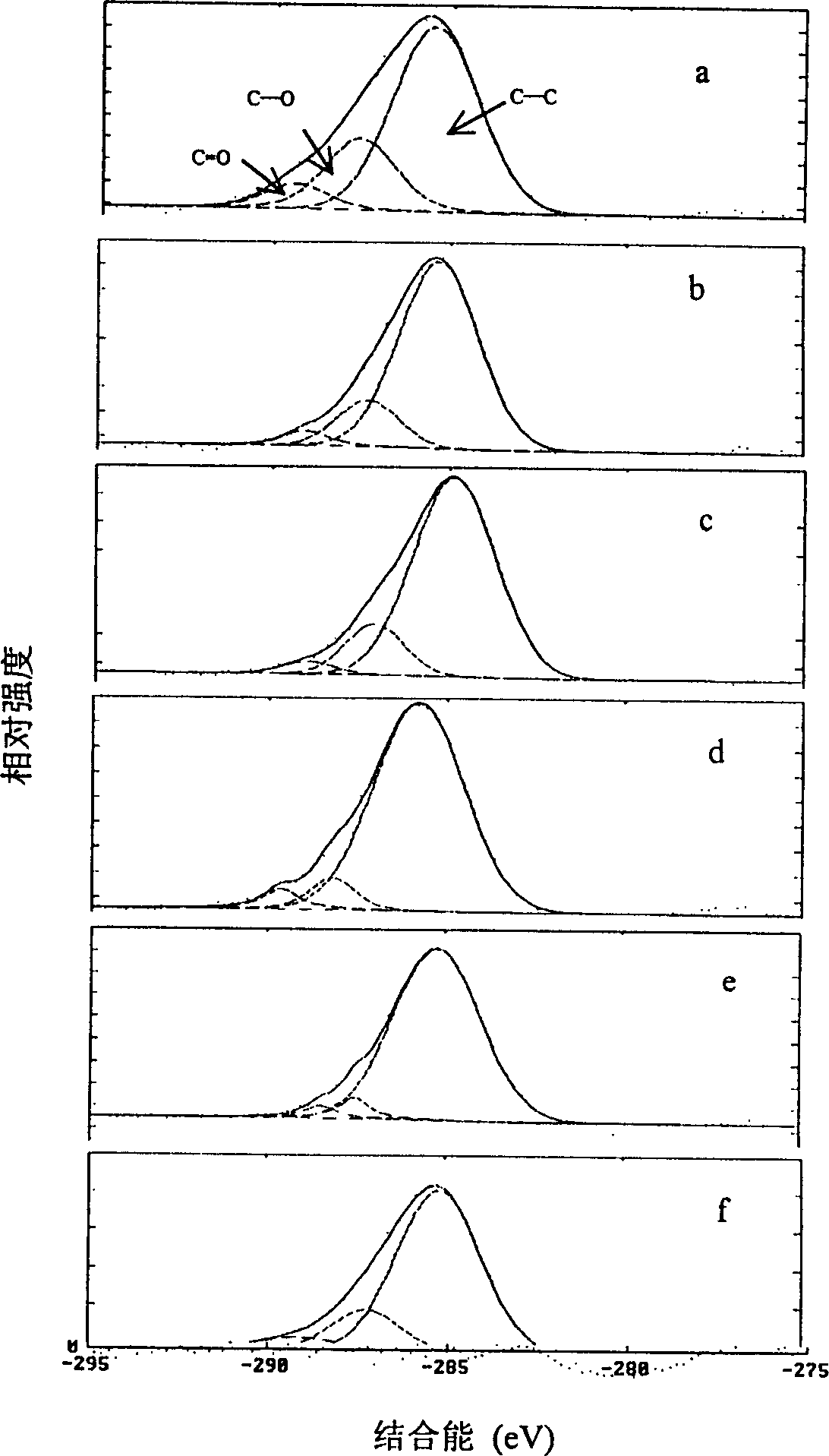

[0037] PGLA with a molecular weight of 200,000 is melted on the glass sheet and cooled into a uniform transparent film. Put it into a 13.56MHz glass plasma reactor with a diameter of 10cm and a length of 55cm. The electrodes are capacitively coupled. Vacuum to vacuum degree 3.5×10 -2 pa, into the vinyl acetic acid solution, through the argon into the reactor. Adjust the flow meter to control the gas flow to 30sccm, the vacuum range to 120Pa, the power to 20w, turn on the power supply for discharge polymerization for 2 hours, adjust the pulse ratio to 100-1%, and the time interval of "on" to be 10ms to obtain the polyvinyl acetic acid modified coating PGLA membrane. XPS spectrum of vinyl acetic acid coating as figure 2 Shown, C in C-C, C-O, C=O functional groups 1s The atomic binding energies are 284.6eV, 286.0eV, and 287.6eV, respectively. From figure 2 It can be seen that w...

Embodiment 3

[0038] Example 3 Immobilization reaction of nerve regeneration promoter CNTF on membrane

[0039] The PGLA membrane modified with lysine plasma coating prepared in Example 1 was sterilized with ethylene oxide at room temperature, and the carbodiimide biocatalyst was formulated into a 20% PBS solution. Nerve regeneration-promoting factor CNTF (ciliary neurotrophic factor) was made into PBS aqueous solution with a concentration of 50ng / ml. The PGLA membrane was placed in the carbodiimide solution for 30 minutes, rinsed with sterile distilled water after taking it out, and then placed in the CNTF solution with a volume ratio of the solution to the material to be treated at 2:1, and reacted at 4°C for 32 hours. After taking it out, rinse it three times with PBS solution for later use. The concentration of CNTF immobilized on the membrane measured by Elisa method was 13ng / cm 2 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com