Production method of puffed flour made from food grains

A production method and technology for multigrain flour, applied in the production field of puffed multigrain flour, can solve problems such as difficulty in reflecting the nutrition and flavor of multigrain, and achieve the effects of being beneficial to long-term storage, improvement of rheological properties, strong viscosity and elasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

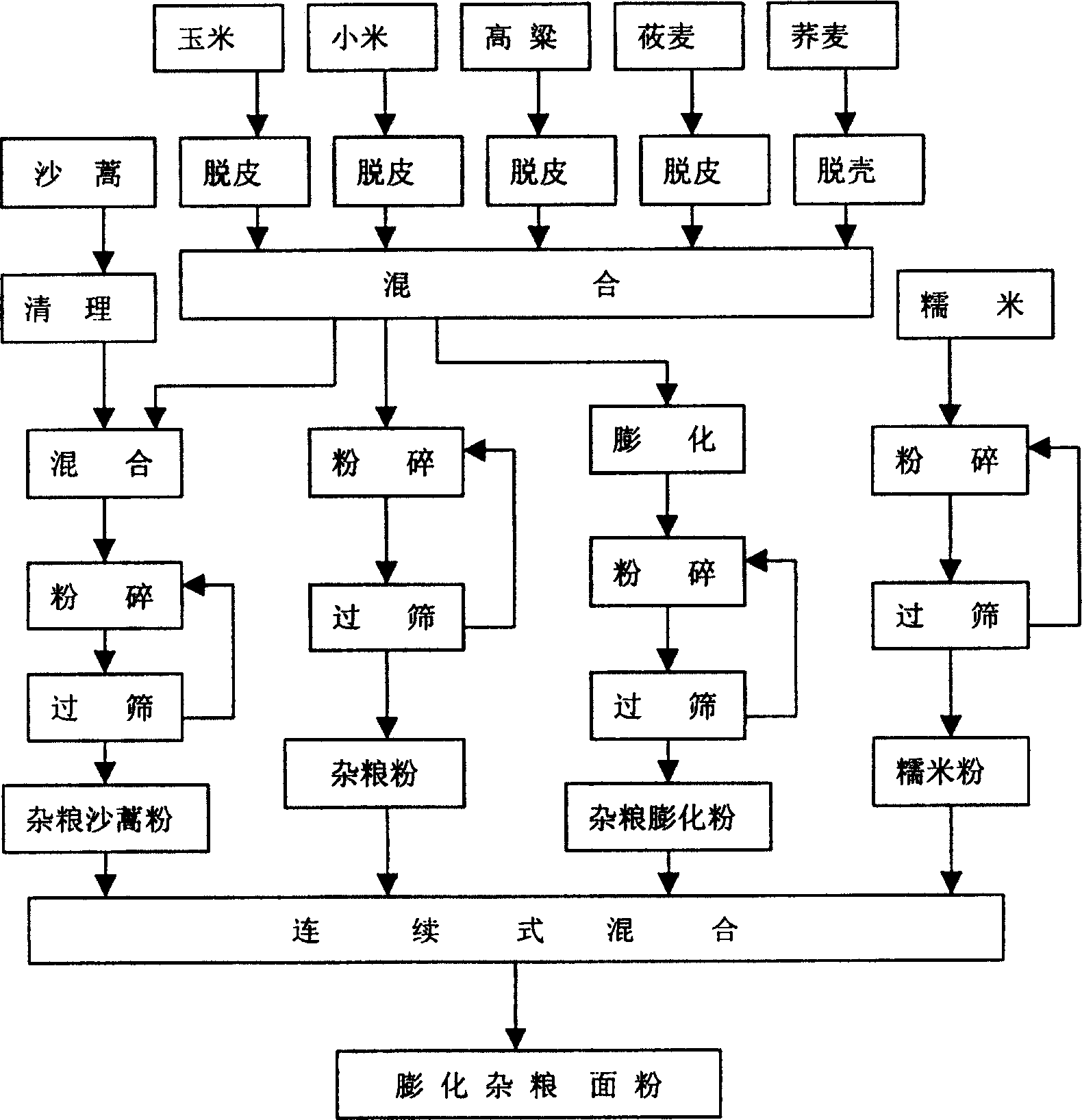

[0007] An example is given below to further describe the present invention: as shown in the production process flow chart, 94 kg each of corn, millet, sorghum, naked oats, and buckwheat are mixed to a total of 470 kg. Divide it into three parts, the first part is 50 kg puffed to make puffed miscellaneous grain powder; the second part 20 kg is mixed with 20 kg Artemisia argyi, crushed to make 40 kg fineness of 100 meshes Artemisia alba powder, moisture is controlled at 12% 400 kilograms of the third part are ground into fineness and are 100 mesh miscellaneous grain powders. Then 10 kilograms of glutinous rice are pulverized into fineness and are 100 mesh glutinous rice flour, and moisture is controlled at 10%. Finally, the prepared 10 kilograms of glutinous rice flour, 40 kilograms of mixed grains Artemisia annua powder, 50 kilograms of expanded mixed grains powder, and 400 kilograms of mixed grains powder were uniformly mixed in a continuous mixer to obtain 500 kilograms of ex...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com