Silver halides colour photographic sensitive material

A technology of color photography and photosensitive materials, applied in photosensitive materials, emulsified silver emulsion, optics, etc., can solve the problems of film strength reduction and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0375] An ethylene terephthalate film support (having a thickness of 120 micrometers) was prepared by applying the coating to an ethylene terephthalate film such that the surface coated with the emulsion was covered with a substrate. The coating was applied and the surface opposite to the emulsion-coated surface was coated with a conductive polymer containing the following (0.05 g / m 2 ) and tin oxide (0.20g / m 2 ) of the acrylic layer.

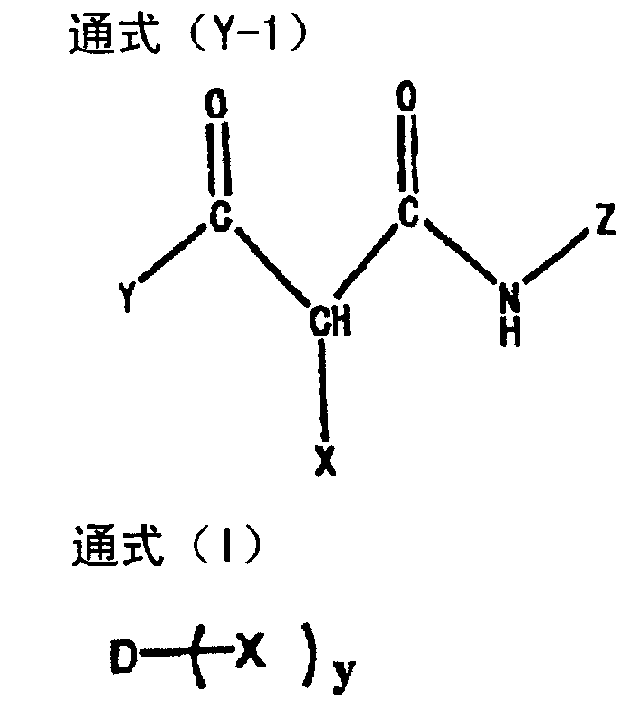

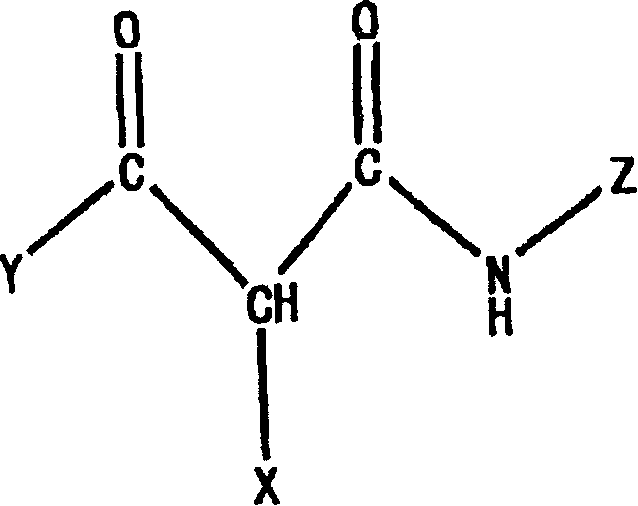

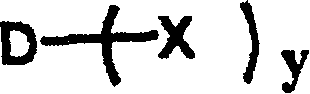

[0376] conductive polymer

[0377]

[0378]

[0379] The methanol-wet filter cake of the exemplary dye (IV-1) was used in an amount equivalent to 240 g wet weight of the exemplary compound (V-12) as a dispersing aid, and the amount of water was such that the total The amount reaches 4000 grams. These materials were loaded with 1.7 liters of zirconia beads (0.5 mm in diameter) into a "jet mill (UVM-2)" (manufactured by Imex Co. / sec peripheral speed grinding for 2 hours. The resulting dispersion product was diluted with water so that ...

Embodiment 2

[0574] Emulsions were prepared according to the procedure of Example 1 except that only the halogen composition was changed to Cl / Br = 99.5 / 0.5 at the grain formation of silver halide emulsions R1 and G1 for the fourth and sixth layers. These emulsions were blended with sensitizing dyes in amounts equal to emulsions R1 and G1 and chemically aged to an optimized degree by adding sulfur sensitizers and gold sensitizers. Samples 201-227 were prepared by substituting these emulsions for emulsions R1 and G1 of samples 102-127. Samples 201 to 227 were subjected to the same treatment as in Example 1 and were subjected to the same evaluation. The same evaluation results were obtained. Accordingly, it can be seen that the present invention is effective in a silver halide photographic photosensitive material using a silver halide emulsion having a higher silver chloride content.

Embodiment 3

[0576] The conditions and formulations of the processing solution used in the developing step in the processing of Example 1 were changed as follows. Also, the 6th and 7th steps (that is, the first fixing step and the subsequent water washing step) are omitted. The color tone and color density of the samples 201 to 227 prepared in Example 2 were evaluated by using the above conditions and the rinse solution. Also, in order to verify whether the unnecessary dye was completely removed, the cyan density in the unexposed area after processing was measured. The less dense the cyan, the more adaptable the material is to rapid washdown. The results are shown in Table 11.

[0577]

[0578] Step Rinsing temperature (°C) Rinsing time (seconds) Supplementary amount

[0579] (based on milliliters of 35 x 30.48 meters)

[0580] 3. Development 39.5±0.1 90 690

[0581]

[0582] Step Chemical name Tank solution Makeup solution

[0583] devel...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com