Prepn of fatty alcohol acetate

A technology of fatty alcohol ester and fatty alcohol, which is applied in the reaction preparation of ester group and hydroxyl group, organic chemistry, etc., can solve the problem of difficult transesterification reaction, etc., and achieve the effect of high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

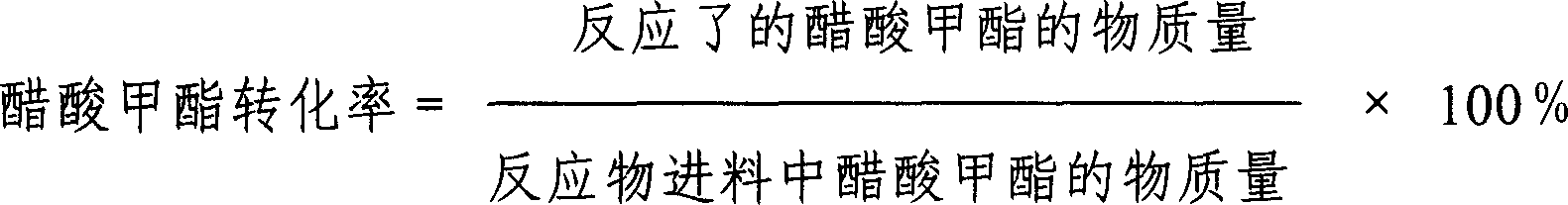

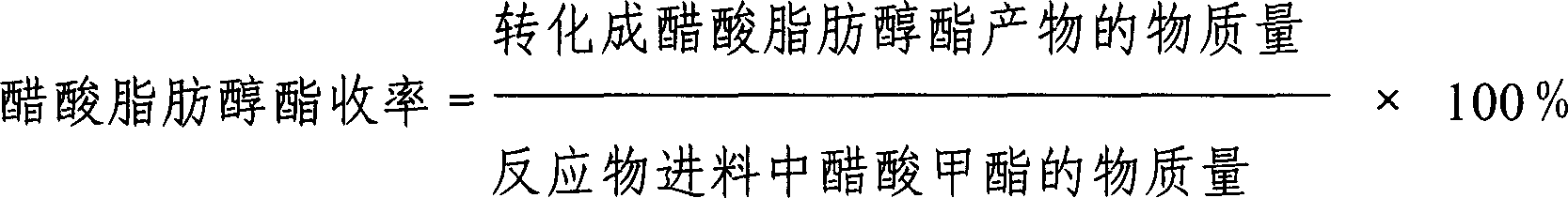

Method used

Image

Examples

Embodiment 1~4

[0020] Add a fatty alcohol with a purity of more than 95%, polyvinyl acetate and methyl acetate mixture (the content of methyl acetate is 60-85%) produced by methanolysis to produce polyvinyl alcohol, and add a mixture with reflux according to the required feeding ratio In the enamel reactor of the condenser, and add the required amount of catalyst. The reactant is heated to a suitable temperature under pressure with stirring. After a suitable reaction time, the reaction material is taken and the content of each component in the reaction product is detected by chromatographic analysis, and the reaction result is calculated. After the reaction is finished, the reaction product is separated and purified to obtain the corresponding fatty alcohol acetate product.

[0021] See Table 1 and Table 2 for specific fatty alcohol raw materials, catalysts and their consumption, and specific reaction conditions, and Table 3 for the reaction results.

[0022] fatty alcohol raw m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com