Propene gas recovery device used in production of polypropene by bulk-polymerization and process thereof

A technology of gas recovery and polypropylene, which is applied in the field of chemical organic polymer compounds with carbon-carbon unsaturated bonds, can solve the problems of unsafe atmosphere, waste of propylene resources, and reduction of enterprise benefits, so as to prevent combustion and explosion hazards, The effect of reducing production costs and improving working conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

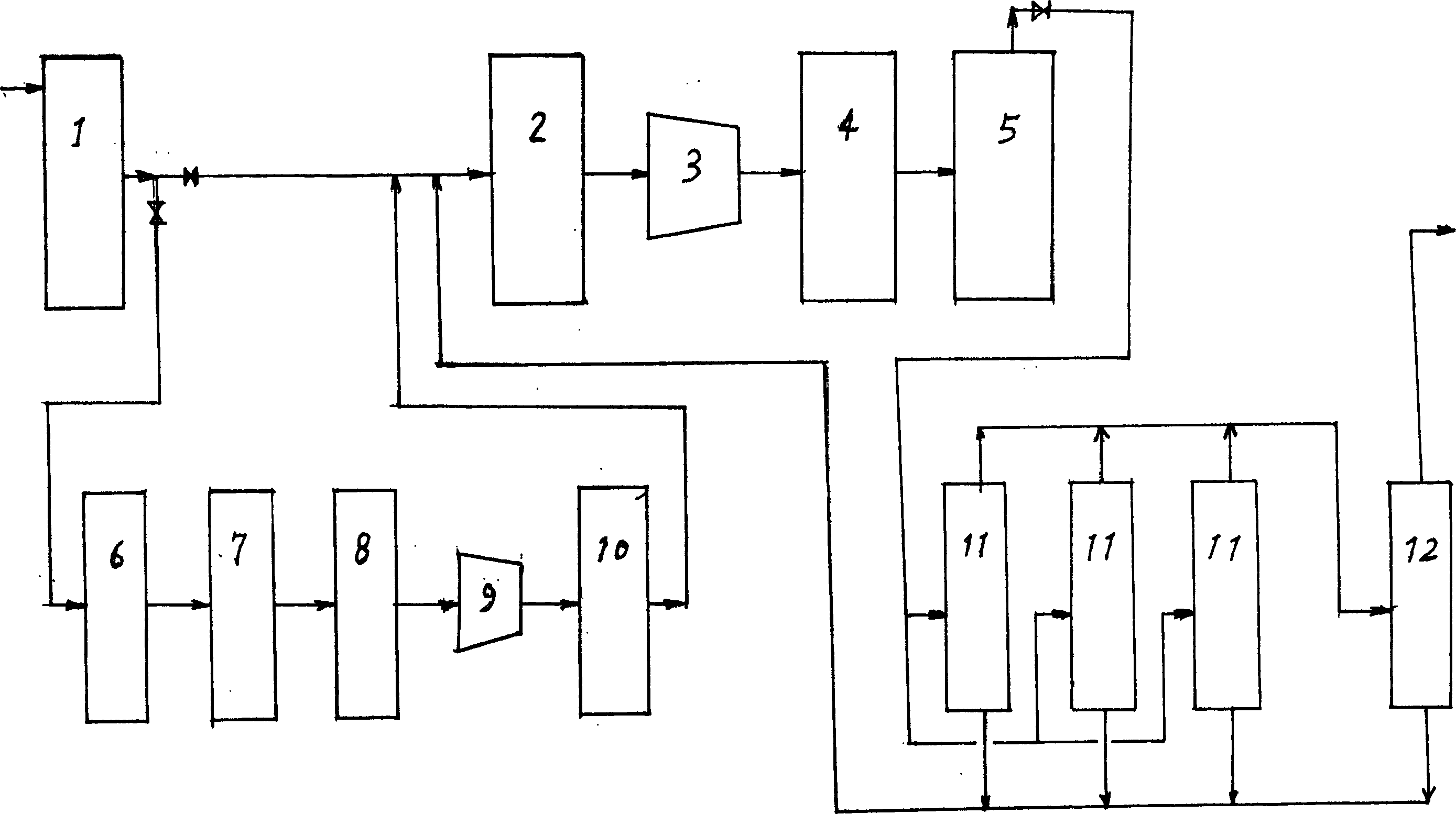

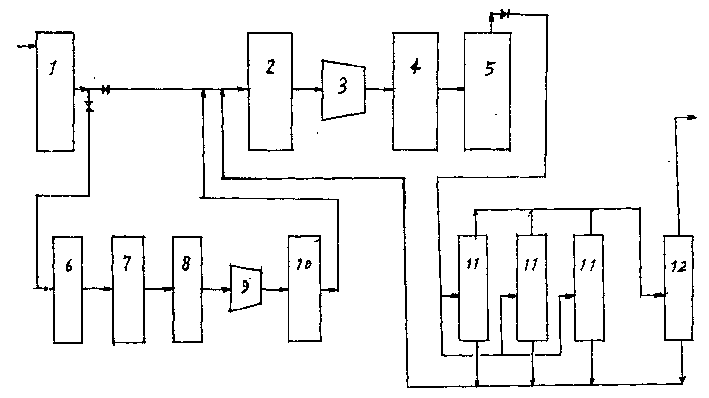

[0022] See figure 1 :

[0023] 1. When the internal pressure of the mixed gas of propylene and nitrogen with an oxygen content of less than 1% in the flash tank (1) is greater than 0.05 MPa, use positive pressure to directly discharge the mixed gas of propylene and nitrogen into the wet gas cabinet (2) Without opening the vacuum recovery system.

[0024] 2. When the internal pressure in the flash tank (1) is less than 0.05MPa, due to the positive pressure of the wet gas tank (2), the mixed gas of propylene and nitrogen cannot be directly sent into the wet gas tank, and the vacuum recovery system is turned on, that is, the flash is turned off A valve between the kettle (1) and the wet gas holder (2). Simultaneously, turn on the vacuum recovery compressor (9) to evacuate, so that the low-pressure propylene and nitrogen mixed gas in the flash tank (1) will pass through the filter tank (6) to filter impurities successively, the buffer tank (7) buffers, and the gas-liquid separat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com