Structure of flash memory unit with planar surround grid and its manufacturing methods

A technology of storage unit and manufacturing method, which is applied in semiconductor/solid-state device manufacturing, electrical components, electric solid-state devices, etc., and can solve problems such as leakage current deterioration and leakage current deterioration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

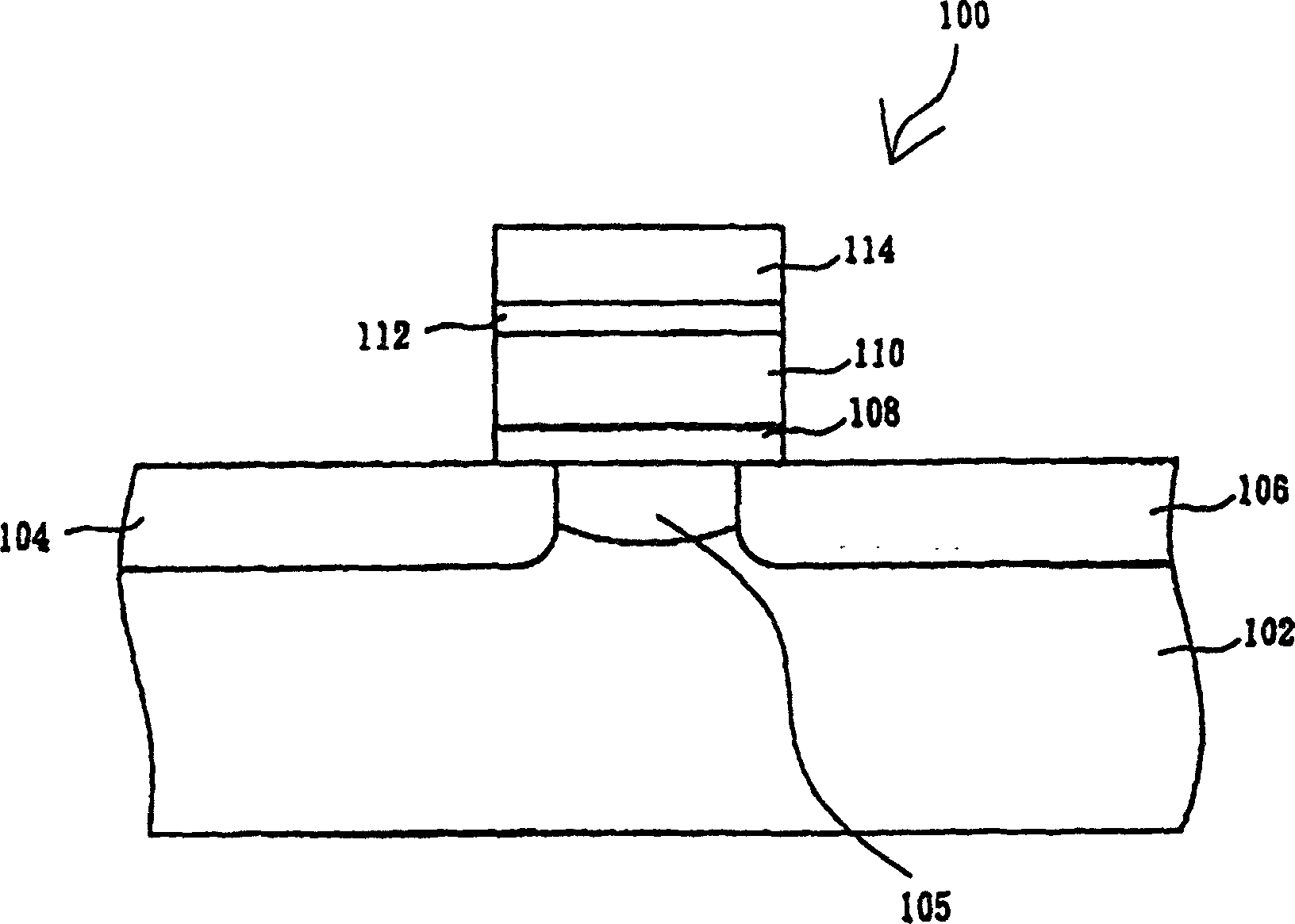

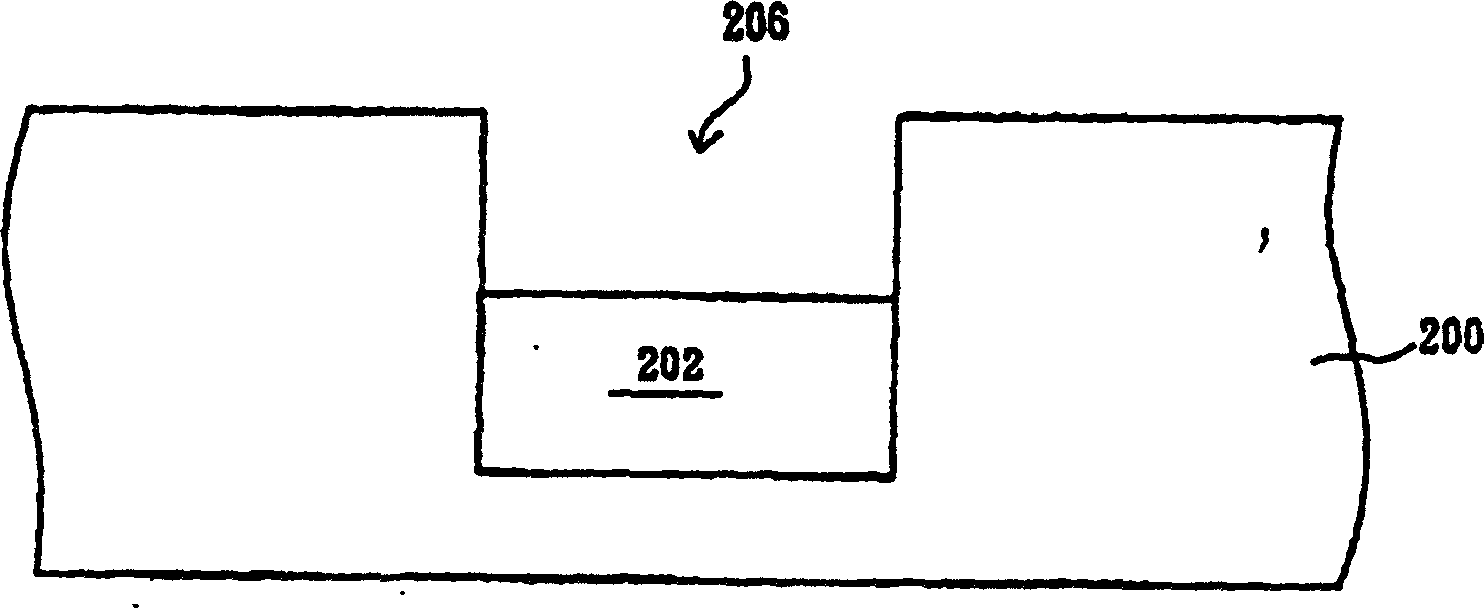

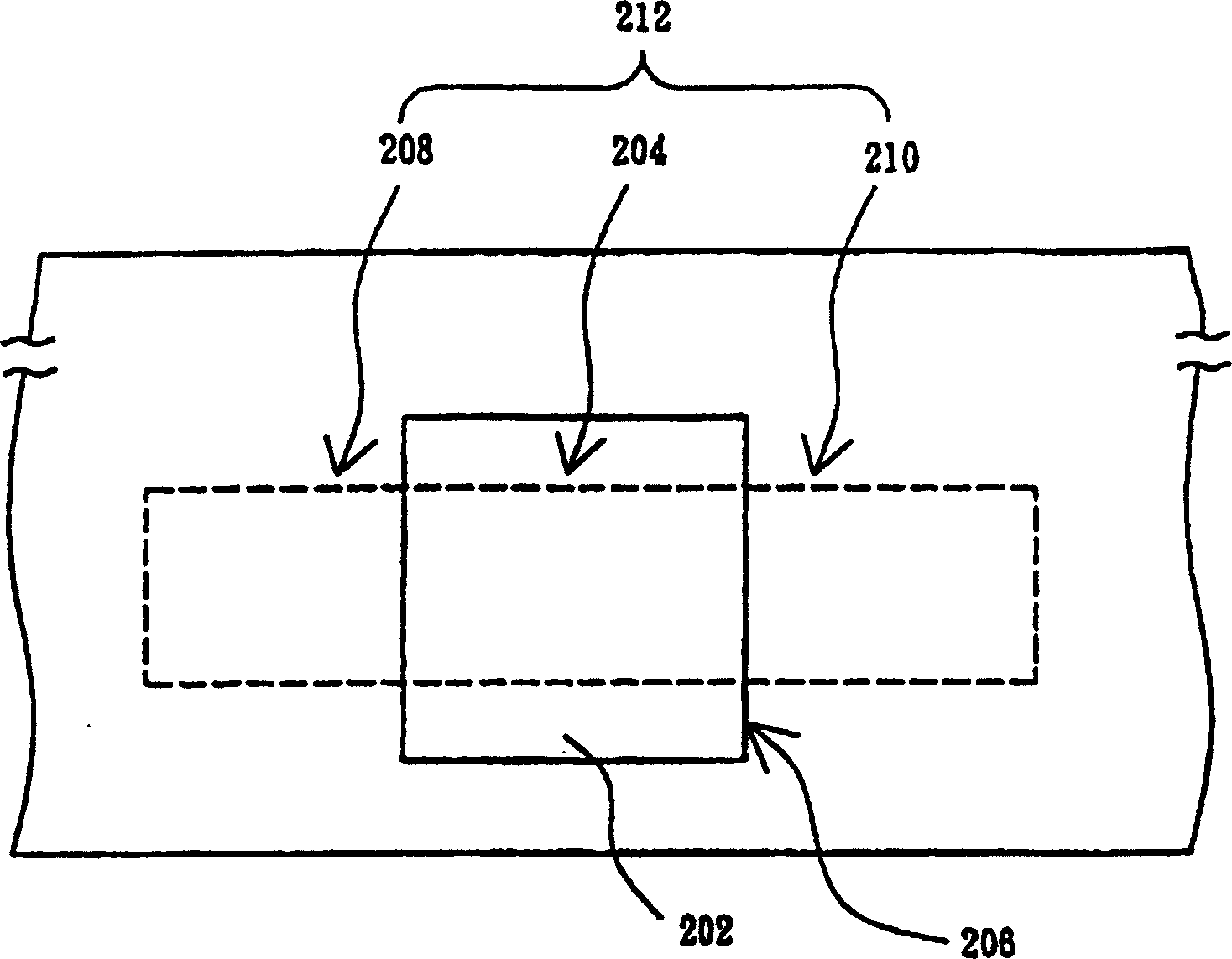

[0029] With the popularization of portable electronic products, the demand for flash memory is greatly increased. How to develop a new generation of flash memory and reduce the size of flash memory cells has become an important research trend. The invention discloses a structure of a planar surrounding gate flash memory unit and a manufacturing method thereof. The planar surrounding gate flash memory unit of the invention can effectively reduce the leakage current between the source and the drain, and can increase the unit current in the open state. Moreover, a higher capacitive coupling ratio between the floating gate and the control gate can be obtained without changing the unit size, so as to achieve the purpose of reducing the writing / erasing voltage of the flash memory unit. In order to make the narration of the present invention more detailed and complete, refer to the following description and cooperate Figure 2 to Figure 15 icon. Please refer to figure 2 as well ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com