Positive photoresist composition

A technology of composition and photoresist, which is applied in the direction of optics, optomechanical equipment, photosensitive materials for optomechanical equipment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

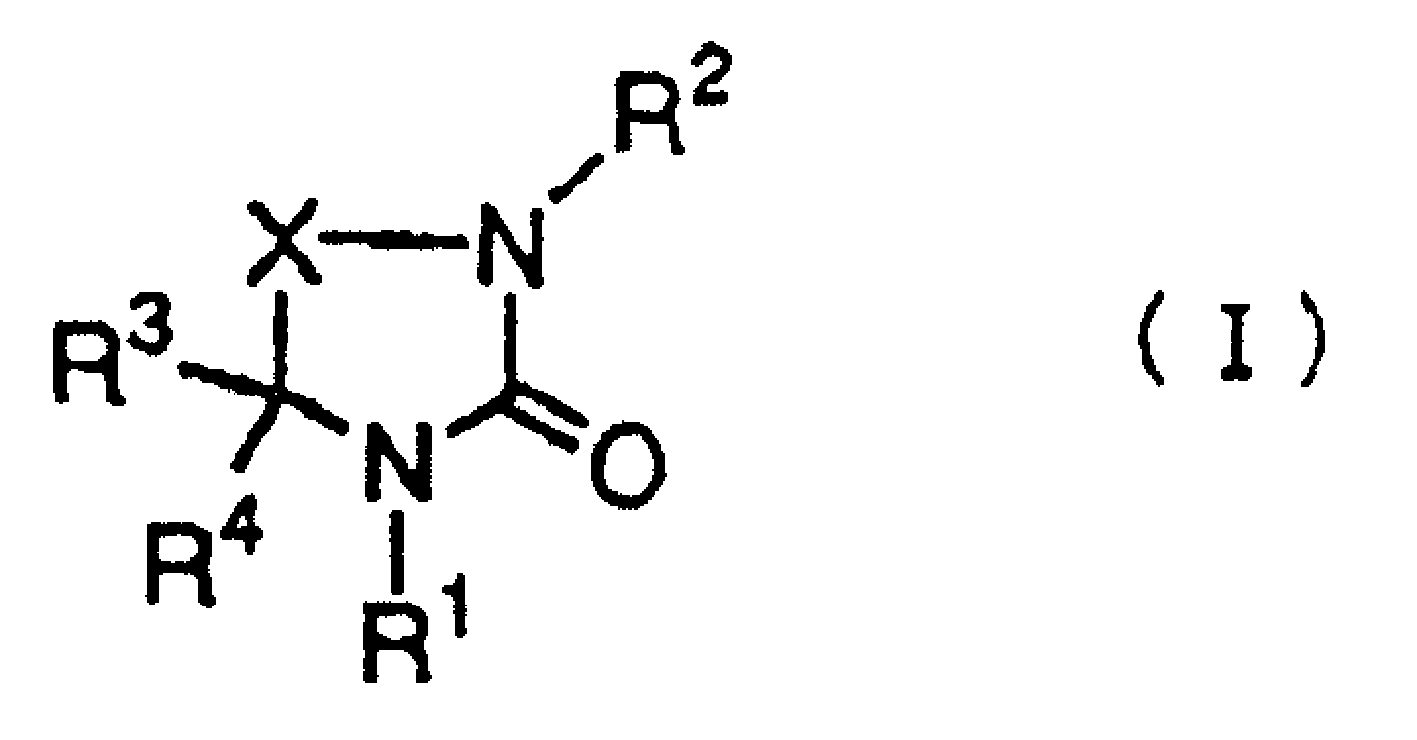

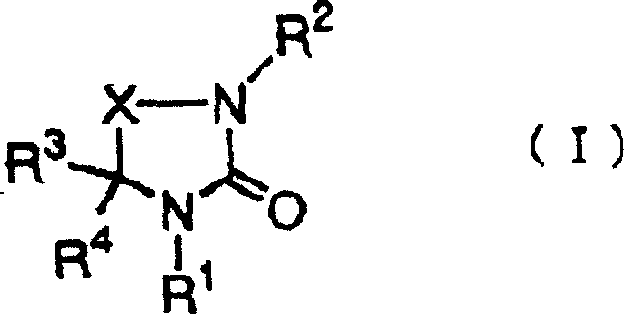

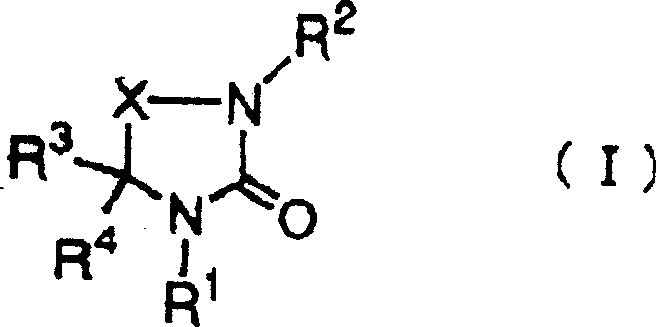

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0056] The components were mixed in the following composition, and filtered through a fluororesin filter having a pore size of 0.1 µm to form a photoresist solution.

[0057] Resin:

[0058] With reference to the resin prepared in the examples, 13.5 parts

[0059] Acid Generators:

[0060] Bis(cyclohexanesulfonyl)diazomethane, 0.42 parts

[0061] (4-Methylphenyl)diphenylsulfonium perfluorooctanesulfonate, 0.08 parts

[0062] Quencher: N-methyldicyclohexylamine, 0.012 parts

[0063] Additive: 1,3-dimethyl-2-imidazolinone, 1.0 parts

[0064] Solvent: Propylene Glycol Monomethyl Ether Acetate, 70 parts

[0065] On a silicon wafer washed in a conventional manner, the above photoresist solution was coated with a spin coater so that the film thickness after drying was 0.7 µm. The silicon wafer was then prebaked at 90°C for 60 seconds on a hot plate. The coated film was exposed through a chromium mask with a hole pattern and the exposure was varied stepwise using a KrF laser w...

Embodiment 2

[0070] A photoresist solution was prepared in the same manner as in Example 1 except that the composition of the photoresist was changed as follows. The product is evaluated in the same way. The results are also shown in Table 1.

[0071] Resin:

[0072] With reference to the resin prepared in the examples, 13.5 parts

[0073] Acid Generators:

[0074] Bis(cyclohexanesulfonyl)diazomethane, 0.4 parts

[0075] (4-Methylphenyl)diphenylsulfonium perfluorooctanesulfonate, 0.1 parts

[0076] Quencher: N-methyldicyclohexylamine, 0.008 parts

[0077] Tetrabutylamine hydroxide 0.004 part

[0078] Additive: 1,3-dimethyl-2-imidazolinone, 1.0 parts

[0079] Solvent: Propylene Glycol Monomethyl Ether Acetate, 70 parts

Embodiment 3

[0081] A photoresist solution was prepared in the same manner as in Example 1 except that the composition of the photoresist was changed as follows. The product is evaluated in the same way. The results are also shown in Table 1.

[0082] Resin:

[0083] With reference to the resin prepared in the examples, 13.5 parts

[0084] Acid Generators:

[0085] Bis(cyclohexanesulfonyl)diazomethane, 0.42 parts

[0086](4-Methylphenyl)diphenylsulfonium perfluorooctanesulfonate, 0.08 parts

[0087] Quencher: N-methyldicyclohexylamine, 0.012 parts

[0088] Additive: 5,5-Dimethylhydantoin, 0.5 parts

[0089] Solvent: Propylene Glycol Monomethyl Ether Acetate, 70 parts

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| molecular weight distribution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com