Process for preparing nano zinc oxide

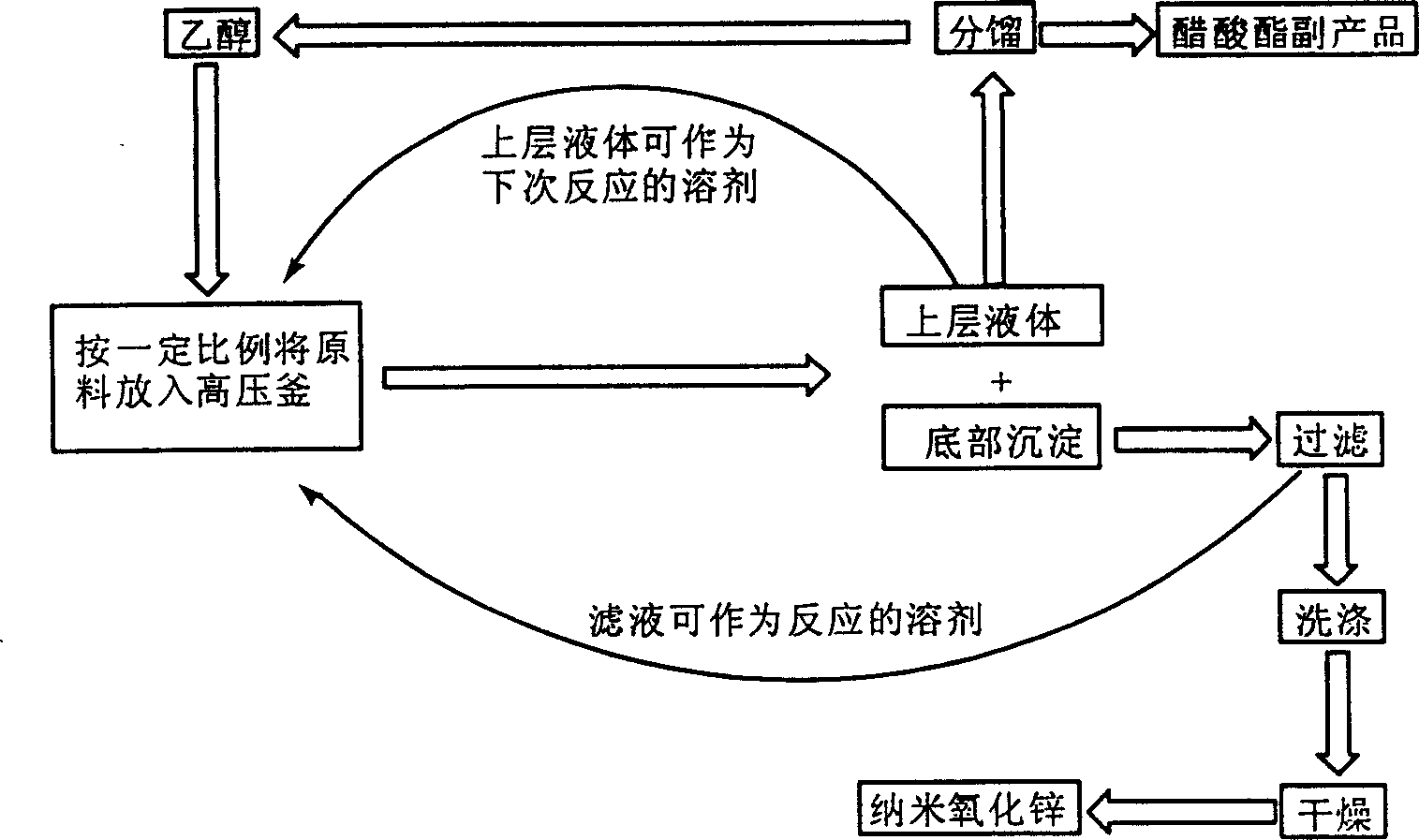

A nano-zinc oxide, zinc acetate technology, applied in the direction of zinc oxide/zinc hydroxide, etc., can solve the problems of easy agglomeration of zinc oxide nanoparticles, complex process and equipment, poor oil dispersion, etc. The effect of industrial promotion and moderate esterification reaction speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

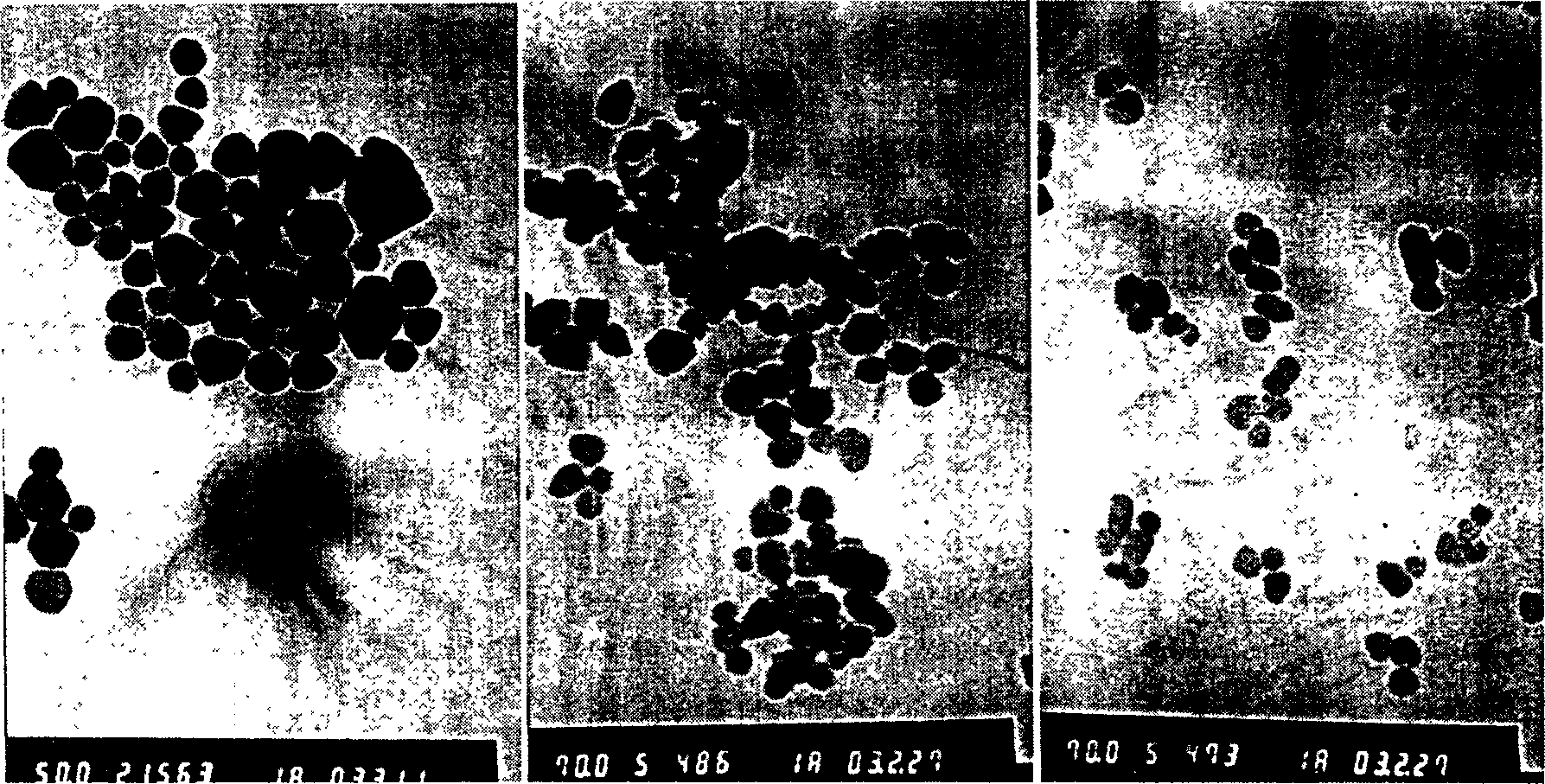

[0041] Methanol and zinc acetate were put into an autoclave at a ratio of 5:1 (mL / g), and the filling volume was 60%. After tightening, put it into an oven and react at 200°C for 2 hours. After the reaction was completed, it was naturally cooled to room temperature. The upper liquid was removed, and the bottom precipitate was filtered, washed and dried to obtain zinc oxide nanopowder with an average particle size of 30nm.

Embodiment 2

[0043] Put 2v% methanol aqueous solution (volume ratio methanol: water = 1:50) and zinc acetate at 50:1 (mL / g) into an autoclave with a filling capacity of 60%, screw it tightly and place it in an oven, and react at 200°C for 4 hours . After the reaction was completed, it was naturally cooled to room temperature. The upper liquid was removed, and the precipitate at the bottom was filtered, washed and dried to obtain zinc oxide nanopowder with an average particle size of 40nm.

Embodiment 3

[0045] Ethanol and zinc acetate were put into an autoclave at a ratio of 10:1 (mL / g), and the filling volume was 60%. After tightening, put it into an oven and react at 100°C for 24 hours. After the reaction was completed, it was naturally cooled to room temperature. The upper liquid was removed, and the precipitate at the bottom was filtered, washed and dried to obtain zinc oxide nanopowder with an average particle size of 40nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com