Rare-earth magnet and Manufacturing method thereof

A rare earth magnet and manufacturing method technology, applied in the direction of magnetic materials, magnetic objects, inorganic materials, etc., can solve the problems of rising prices of magnets, stable supply of magnets, etc., to improve the characteristics of magnets, prevent the deterioration of magnet characteristics, improve the safety effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] Hereinafter, embodiments of the present invention will be described with reference to the drawings.

[0045] [raw material alloy]

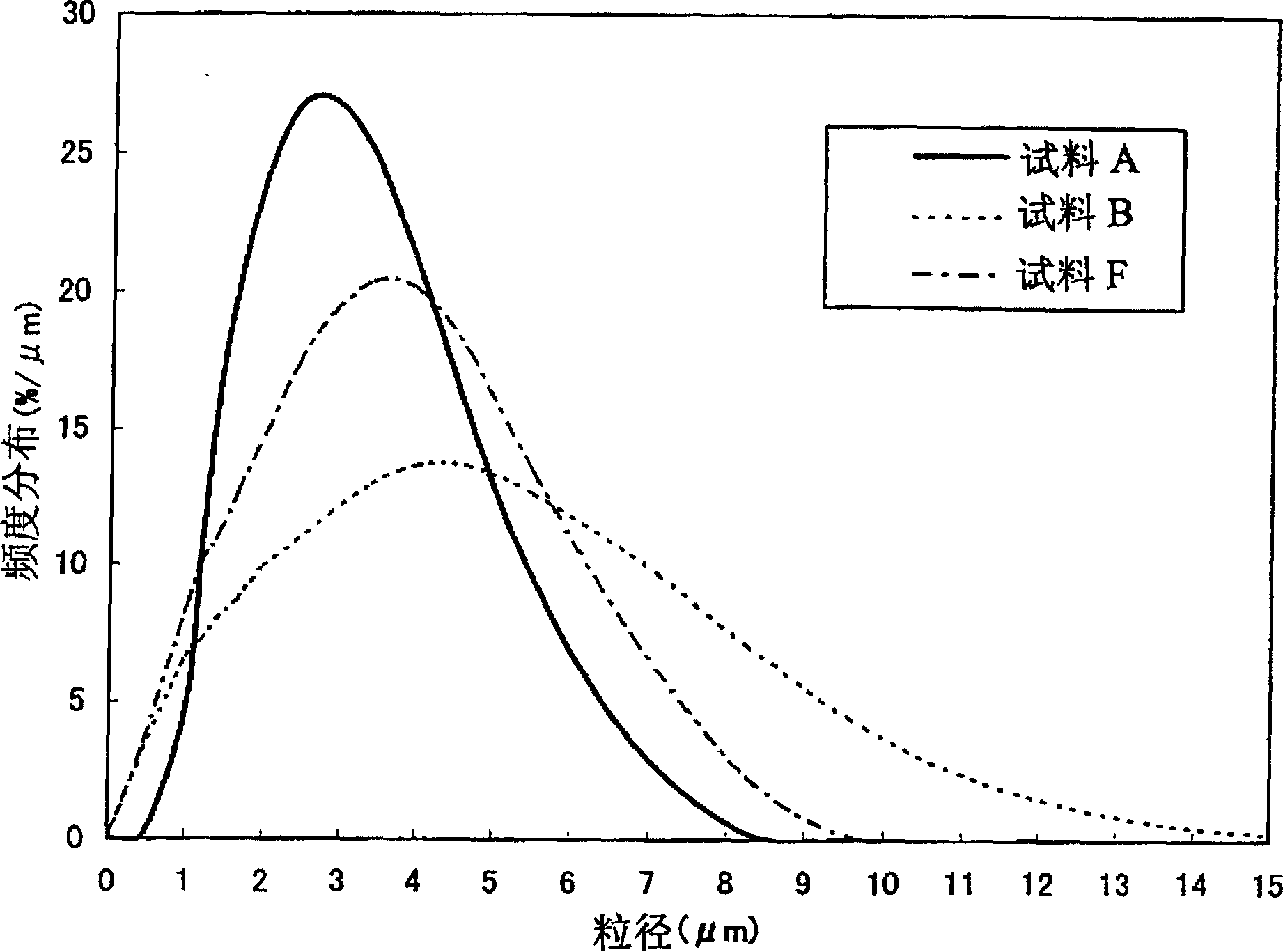

[0046] First, a raw material alloy of an R-Fe-B-based magnet alloy having a desired composition is prepared by a known strip casting method, and stored in a predetermined container. Specifically, first, an alloy having Nd: 8 to 30 at % (atomic %), B: 2 to 28 at %, and the remainder consisting of iron and unavoidable impurities is melted by high-frequency melting to form an alloy melt. liquid. Al, Ti, Cu, V, Cr, Zr, Ga, Mo, Nb, Mo, In, Sn, Hf, TaW, etc. can also be added to the alloy. After keeping the alloy melt at 1350° C., the alloy melt was rapidly cooled by a single roll method to obtain a flake alloy ingot with a thickness of about 0.3 mm. The rapid cooling conditions at this time were that the peripheral speed of the roll was 1 m / sec, the cooling rate was 500°C / sec, and the supercooling was 200°C. The quenched alloy slabs produced...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com