Method for treating wastewater of carbonization by using microbe

A technology for microbial treatment and coking wastewater, applied in the direction of sustainable biological treatment, biological water/sewage treatment, chemical instruments and methods, etc., can solve the problem of poor treatment effect of coking wastewater

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

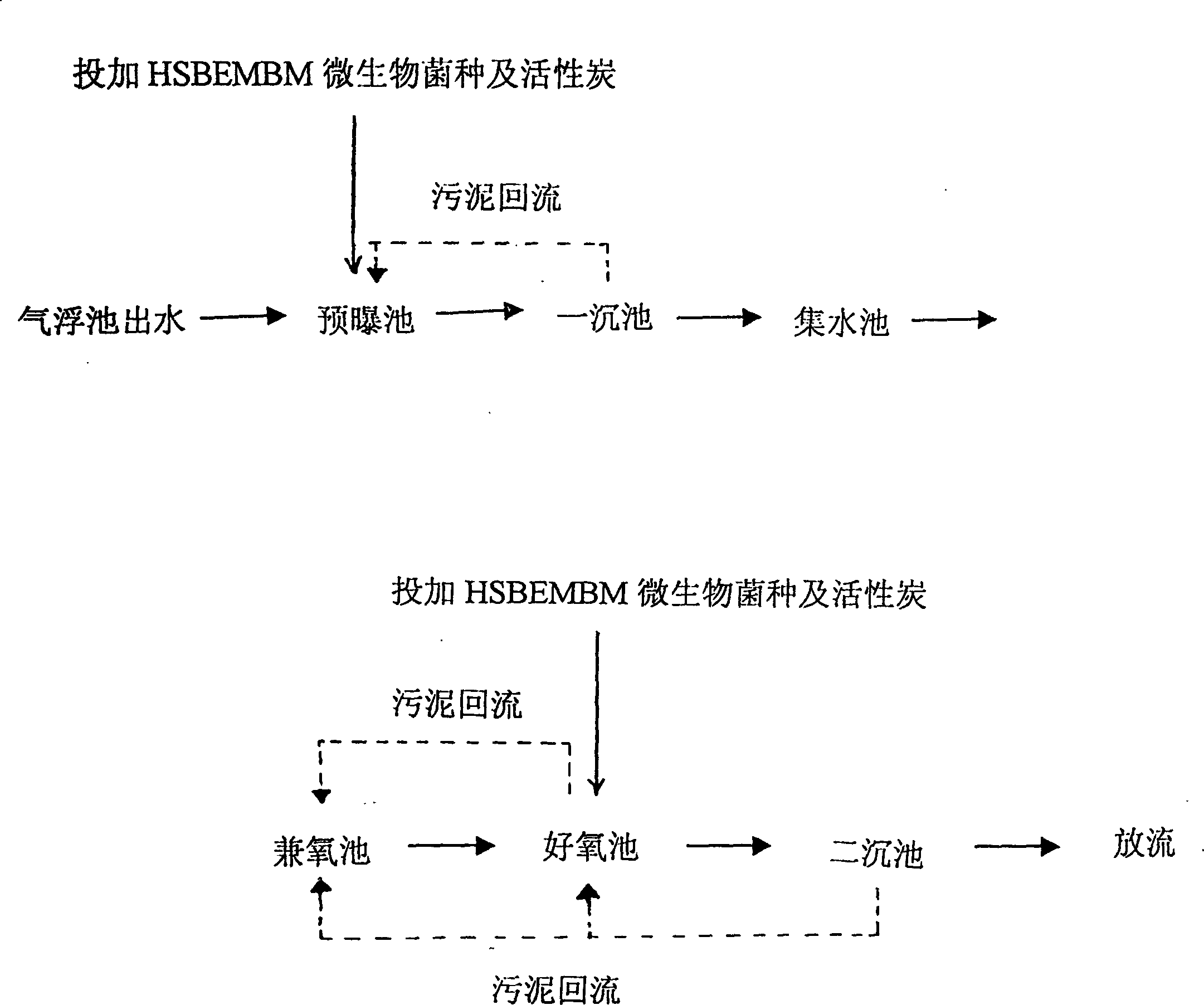

[0126] The method for treating coking wastewater by using microorganisms disclosed in the present invention will be described in detail below with reference to the accompanying drawings.

[0127] Such as figure 1 As shown, it contains COD, NH 3 -N and volatile phenol, thiocyanate and other organic pollutants coking wastewater first pass through the air flotation tank to remove oil and suspended solids (and slag), and then send the coking wastewater to the pre-aeration system for pretreatment. The wastewater enters first Pre-aeration tank pre-added with HSBTMBM preparation of 1.5%-4.0% of the pre-aeration tank volume and activated carbon powder of 1.0%-2.5% of the pre-aeration tank volume. The temperature is controlled at 15-40°C, the pH value is 6.5-9.0, and the dissolved oxygen is 0.6 ~3.2mg / L, sludge sedimentation ratio SV 30 10%-25%, residence time 12-28 hours, influent COD index 1500-3500mg / L, effluent COD index 400-650mg / L, COD degradation efficiency 40%-75%, various effects ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com