Glass panel

A glass panel, flat glass technology, applied in parallel glass structure, glass/slag layered products, improvement of windows/doors, etc., can solve the problem of high emissivity of glass, achieve the effect of suppressing emission and improving thermal insulation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

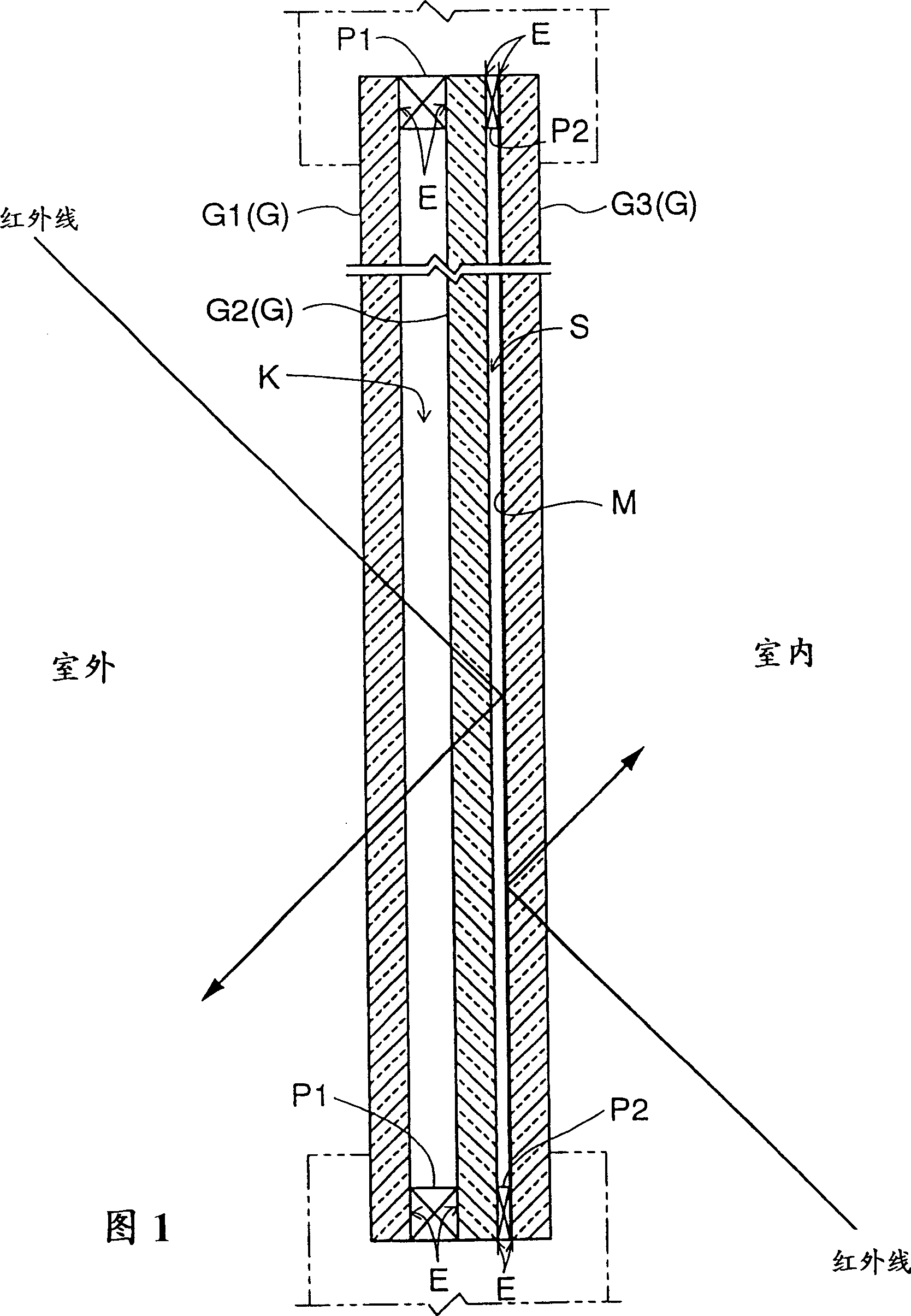

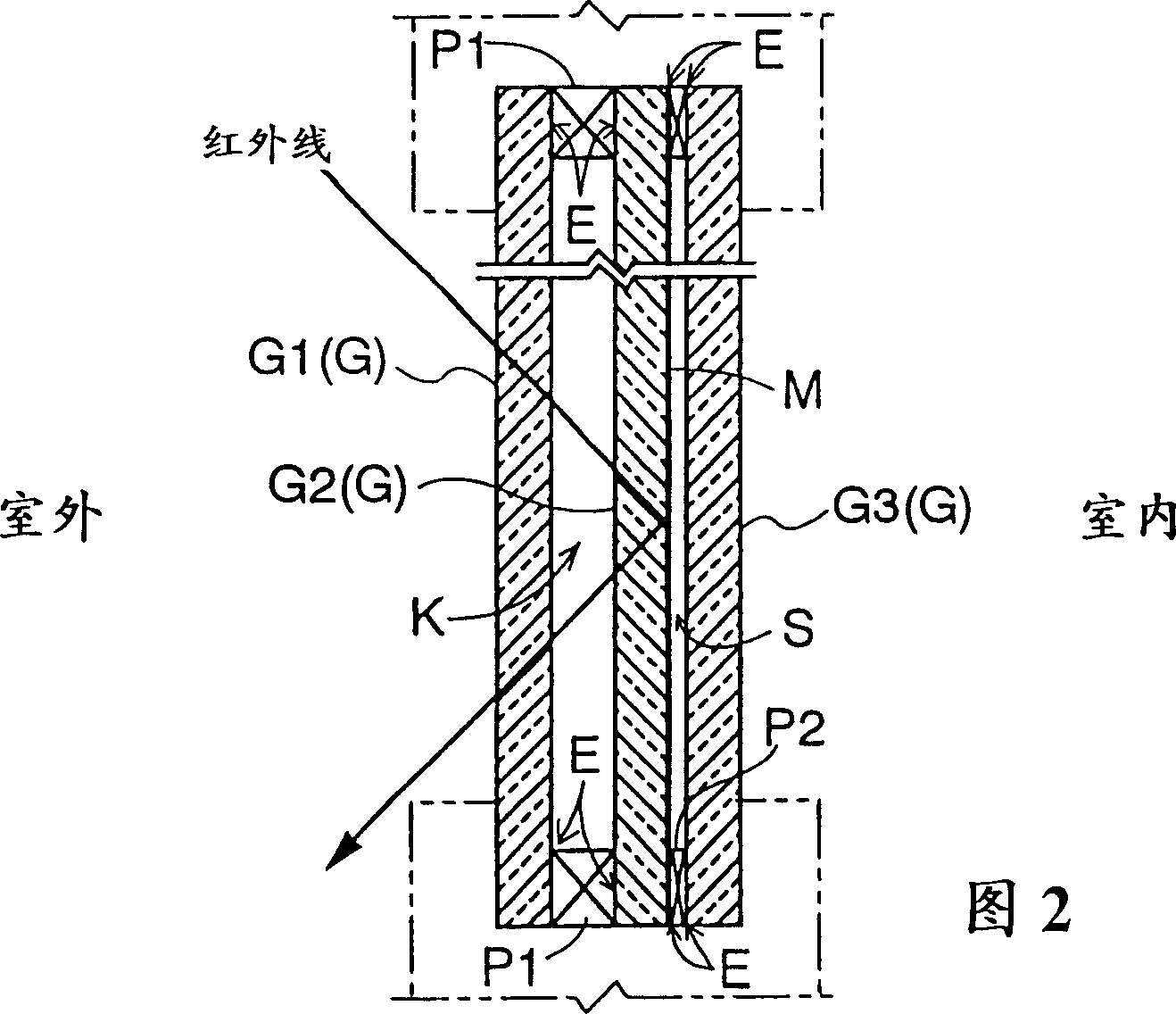

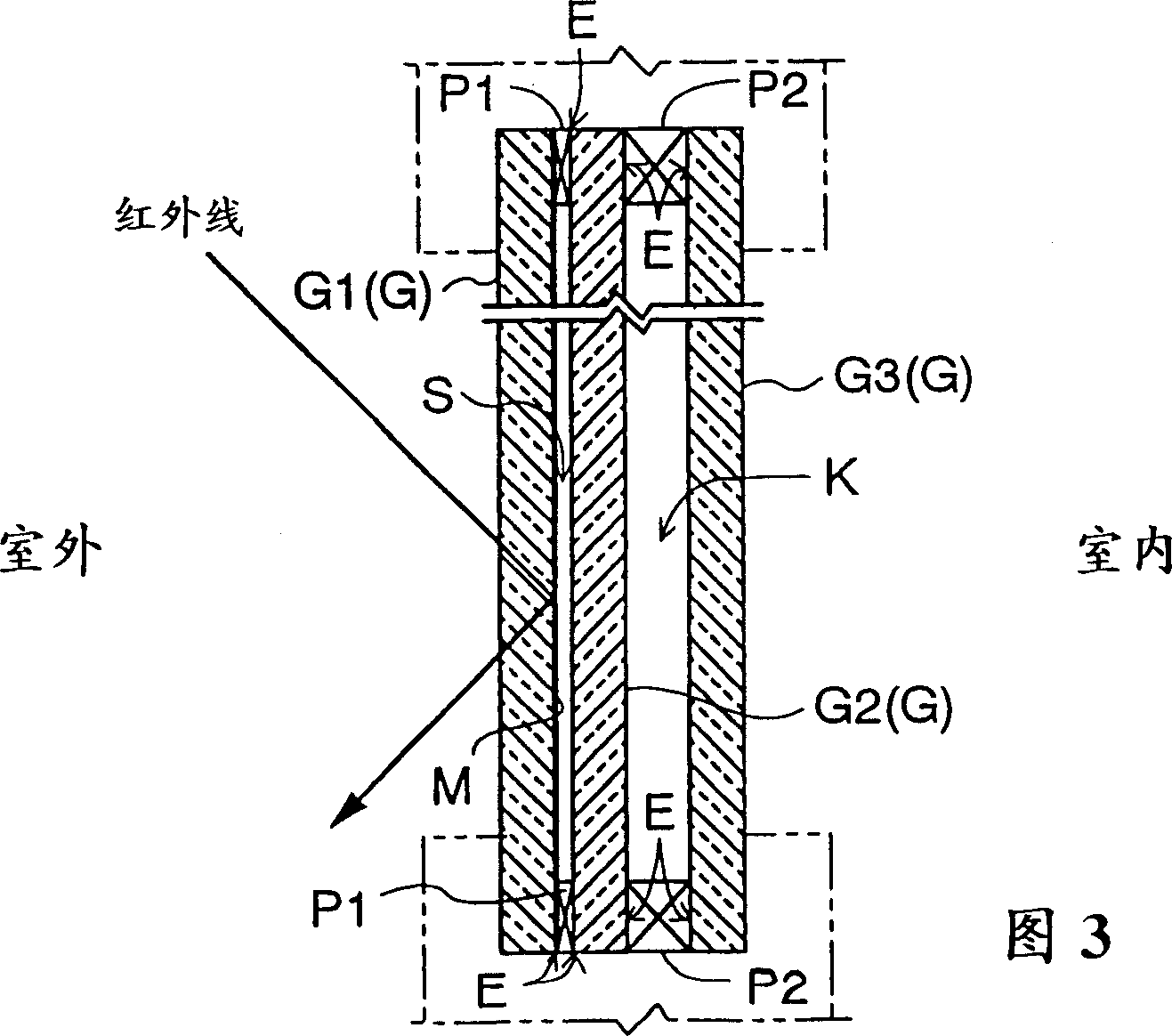

[0061] The low emissivity film layer M of the present invention is that the above-mentioned tin tetrachloride (SnCl 4 ) or dimethyltin dichloride ((CH 3 ) 2 SnCl 2 ), or methyltin trichloride (CH 3 SnCl 3 ), trichlorobutyltin (C 4 h 9 SnCl 3 ) and other tin organic compounds become vapor or mist and are sprayed onto the heated flat glass G mentioned above to obtain. When spraying, if hydrogen fluoride (HF), trifluoroacetic acid (CF) can be properly mixed 3 COOH), polytetrafluoroethylene gas and other fluorine compounds can obtain higher infrared reflection function. The film thickness is preferably about 0.2 to 1.0 μm (2000 to 10000 angstroms), and thus, the emissivity of the obtained plate glass G is about 0.20 to 0.15.

[0062] In addition, the low emissivity film layer M can also be obtained by sputtering. In this case, for example, an oxide film such as tin oxide or zinc oxide is formed as a first layer on the surface of plate glass G, and then silver and the sam...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com