Aretificial nerve canula material of slow operating complex type poly lactic acid and preparation method

A technology of artificial nerves and nerve guides, applied in catheters, medical science, prostheses, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

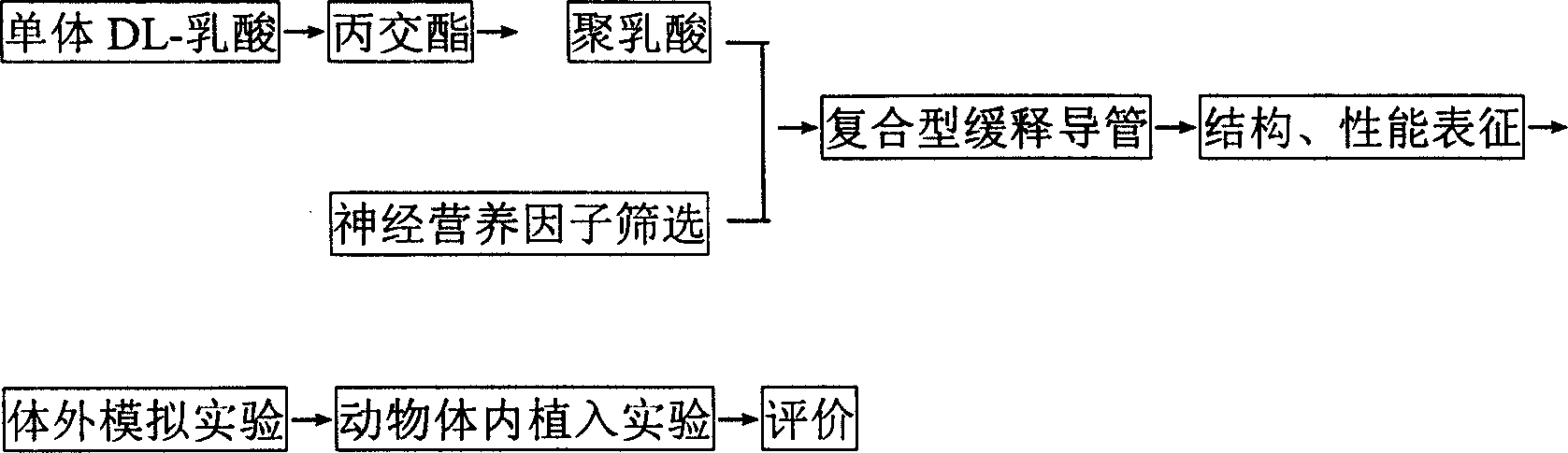

Method used

Image

Examples

Embodiment 1

[0028] 1. PLA Preparation

[0029] The indirect method is used to form PDLLA from lactic acid polymerization dehydration and lactide ring-opening polymerization. The main chemical reaction process is as follows:

[0030]

[0031] The main steps include:

[0032] (1) Preparation of Lactide

[0033] The content is 85wt% D, L-lactic acid is used as the basic raw material, anhydrous zinc oxide is used as the catalyst, the temperature is raised to 130° C., and the water is evaporated by a water pump under reduced pressure. Then rapidly raise the temperature to 230°C, distill under reduced pressure with an oil pump, wash the distilled fraction with ethyl acetate and recrystallize to obtain pure D, L-lactide.

[0034] (2) Ring-opening polymerization of D, L-lactide

[0035] Weigh an appropriate amount of D, L-lactide obtained in step (1) and place it in a clean ampoule, and then inject D, L-lactide mass of 0.3% stannous octoate in chloroform as an initiator. Vacuum with a mech...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com