Method and device for dry distillation and charring of internal combustion self-heating moving bed

A moving bed and dry distillation technology, which is applied in the field of wood pyrolysis, can solve problems such as troublesome logistics and complicated processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

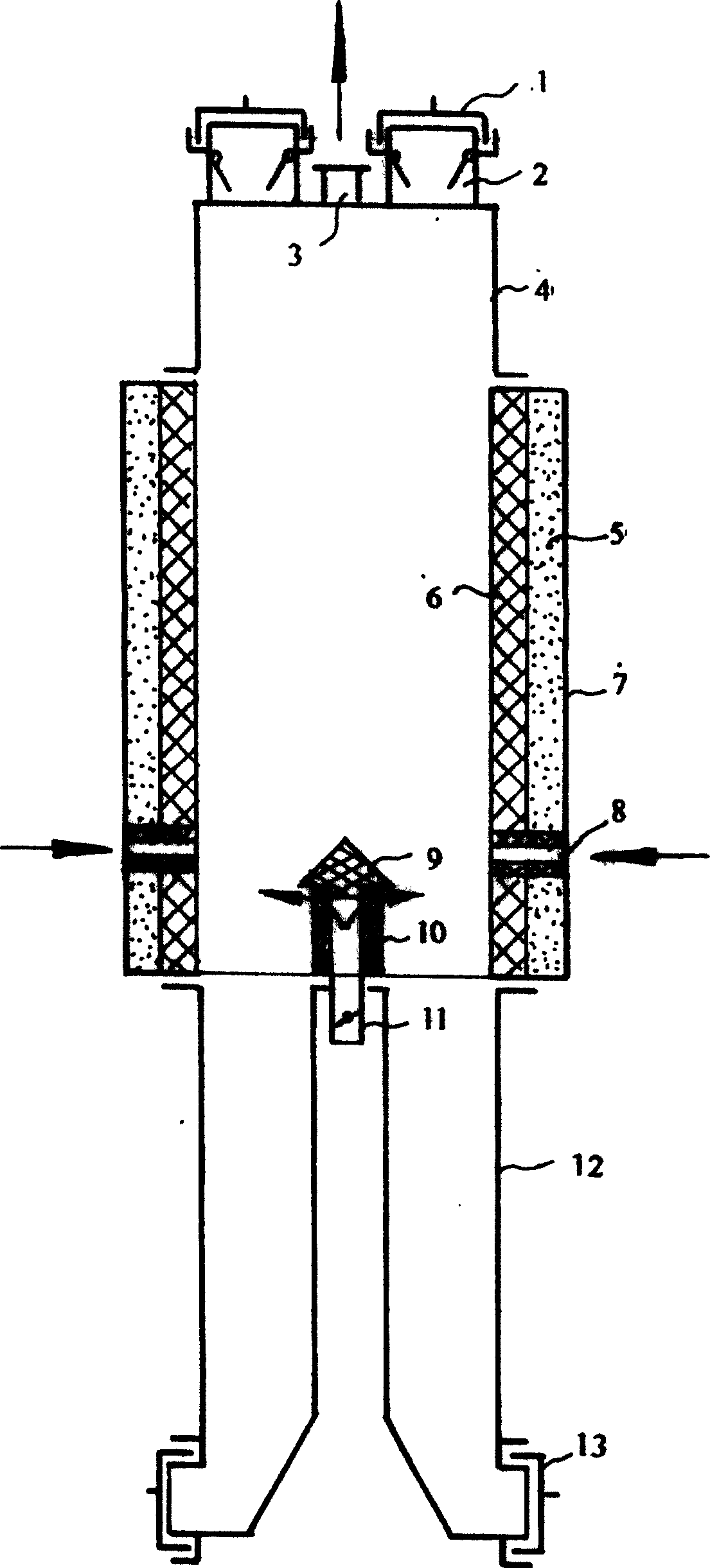

[0013]According to the idea of the present invention, a concept furnace was built, with a total height of about 6.6 meters, of which the preheating and dry distillation carbonization section is about 3.2 meters. The outer shell is made of ordinary steel plates, and the lining is refractory bricks. Rock insulation material, the effective cross-sectional area is about 0.5 square meters; the feeding pipe is about 2.1 meters, made of stainless steel, single-layer structure, natural cooling, the outlet and the outlet cover are sealed with a compressed stuffing box; feeding device The above-mentioned flap valve feeder designed by the inventor is adopted; the dry distillation gas outlet is connected to the condenser through a pipeline, and the outlet of the condenser is connected to an induced draft fan, and the motor of the induced draft fan is speed-regulated by a frequency converter. During production, first fill the furnace cavity with wood (bamboo) charcoal, and then start the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistance | aaaaa | aaaaa |

| iodine adsorption value | aaaaa | aaaaa |

| iodine adsorption value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com