Method for simultaneously producing sodium aluminofluoride and silica white

A technology of white carbon black and cryolite, applied in the field of co-production of cryolite and white carbon black, which can solve the problems of high sodium ion content, poor transparency, and environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

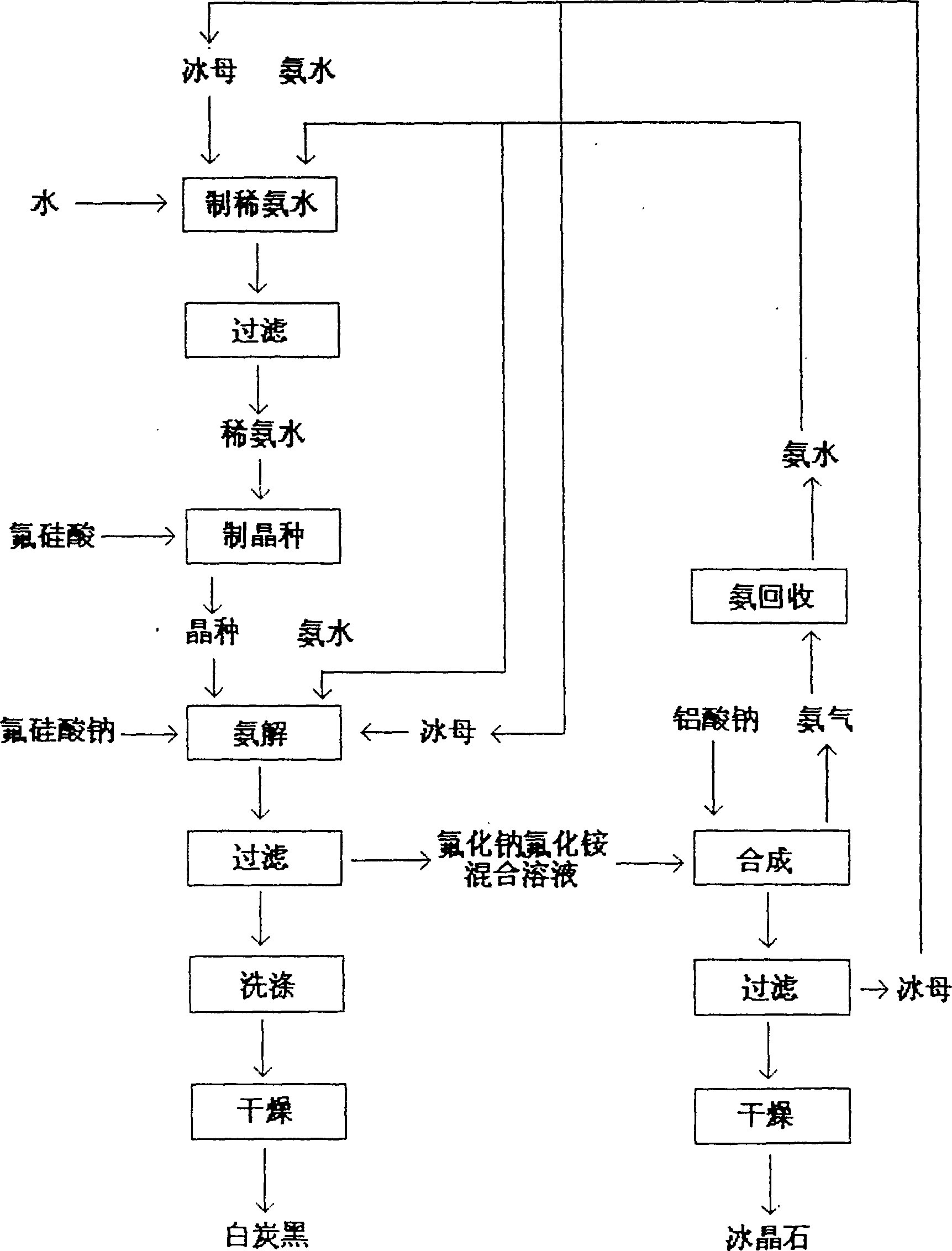

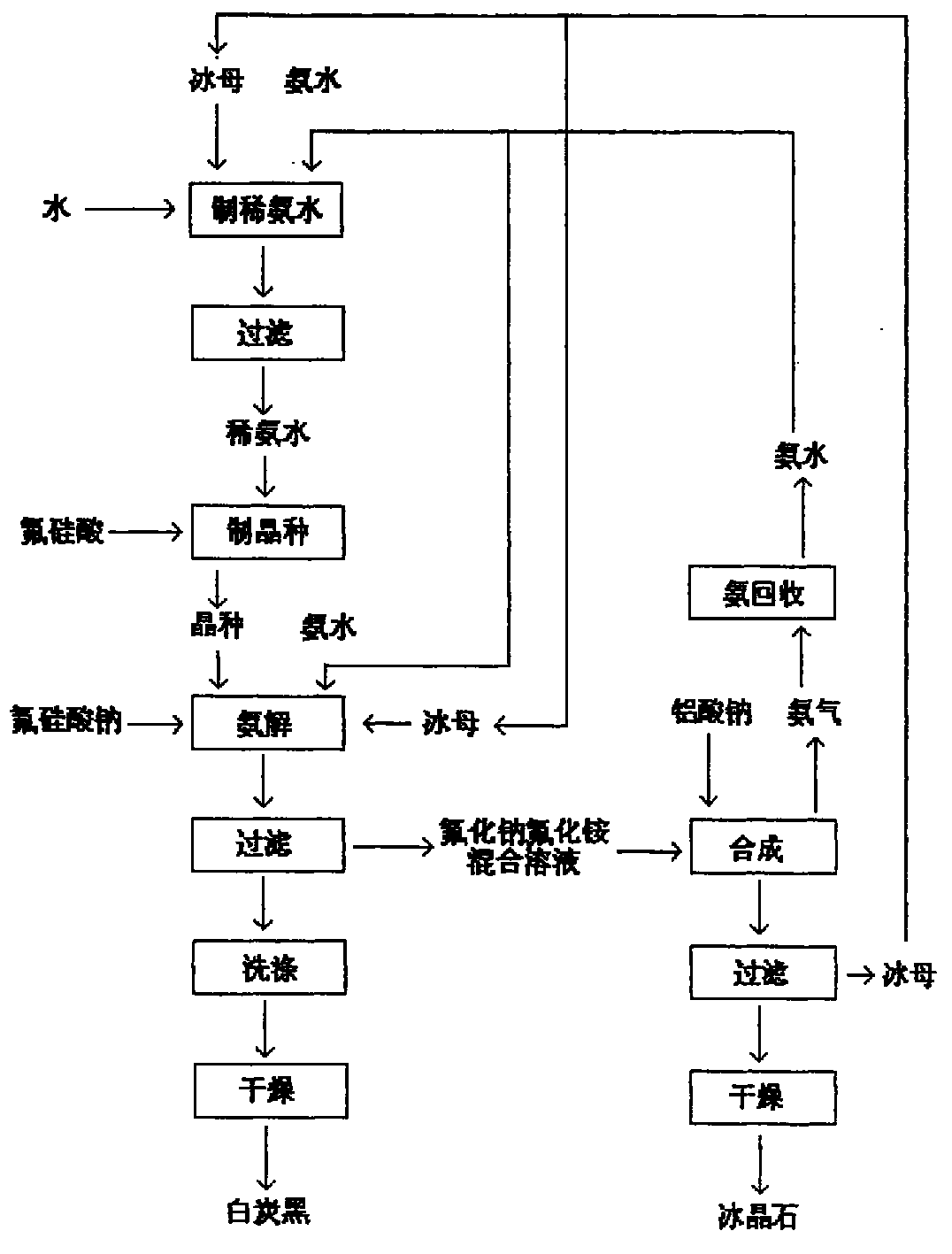

[0030] Such as figure 1 As shown, the method for preparing cryolite co-production white carbon black in the present invention is: add ice mother and ammoniacal liquor to water and prepare dilute ammoniacal liquor, filter to obtain the dilute ammoniacal liquor that concentration is 0.8mol / l, mix fluosilicic acid solution with prepared dilute ammoniacal liquor Ammonia reaction is made white carbon black seed crystal, and the pH value of white carbon black seed crystal is controlled as 6.2, and reaction temperature is 32 ℃; Add 25% white carbon black seed crystal in the ammonolysis tank, and add ice mother, then In the presence of seed crystals, sodium fluorosilicate and ammonia water are subjected to ammonolysis reaction at a temperature of 58°C, the pH value at the end of the reaction is greater than 8.0, and the white carbon black slurry generated by the ammonolysis reaction is filtered and washed to obtain white Carbon black ointment, the filtrate is a mixed solution of ammon...

Embodiment 2

[0032] Such as figure 1 As shown, the method for preparing cryolite co-production white carbon black of the present invention is: add ice mother and ammoniacal liquor to water and prepare dilute ammoniacal liquor, filter to obtain the dilute ammoniacal liquor that concentration is 0.9mol / l, mix fluosilicic acid solution with prepared dilute ammoniacal liquor Ammonia reaction is made white carbon black seed crystal, and the pH value of white carbon black seed crystal is controlled as 7.0, and reaction temperature is 35 ℃; Add 33% white carbon black seed crystal in the ammonolysis tank, and add ice mother, then In the presence of seed crystals, sodium fluorosilicate and ammonia water are subjected to ammonolysis reaction at a temperature of 60°C, the pH value at the end of the reaction is greater than 8.0, and the white carbon black slurry generated by the ammonolysis reaction is filtered and washed to obtain white Carbon black ointment, the filtrate is a mixed solution of ammon...

Embodiment 3

[0034] Such as figure 1As shown, the method for preparing cryolite co-production of white carbon black in the present invention is: add ice mother and ammoniacal liquor to water to prepare dilute ammoniacal liquor, filter the dilute ammoniacal liquor that concentration is 1.0mol / l, mix fluosilicic acid solution with prepared dilute ammoniacal liquor Ammonia reaction is made white carbon black seed crystal, and the pH value of white carbon black seed crystal is controlled as 7.6, and reaction temperature is 40 ℃; Add 40% white carbon black seed crystal in the ammonolysis tank, and add ice mother, then In the presence of seed crystals, sodium fluorosilicate and ammonia water are subjected to ammonolysis reaction at a temperature of about 62 ° C. The pH value at the end of the reaction is greater than 8.0. The white carbon black slurry generated by the ammonolysis reaction is filtered and washed to obtain White carbon black ointment, the filtrate is a mixed solution of ammonium f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com