A kind of Bayer process co-production chemical alumina production method

A production method and chemical technology, which are applied in the preparation of alkali metal aluminate/alumina/aluminum hydroxide, etc., can solve the problems affecting the production increase and circulation efficiency of the Bayer process, and the weak production system of the production system.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

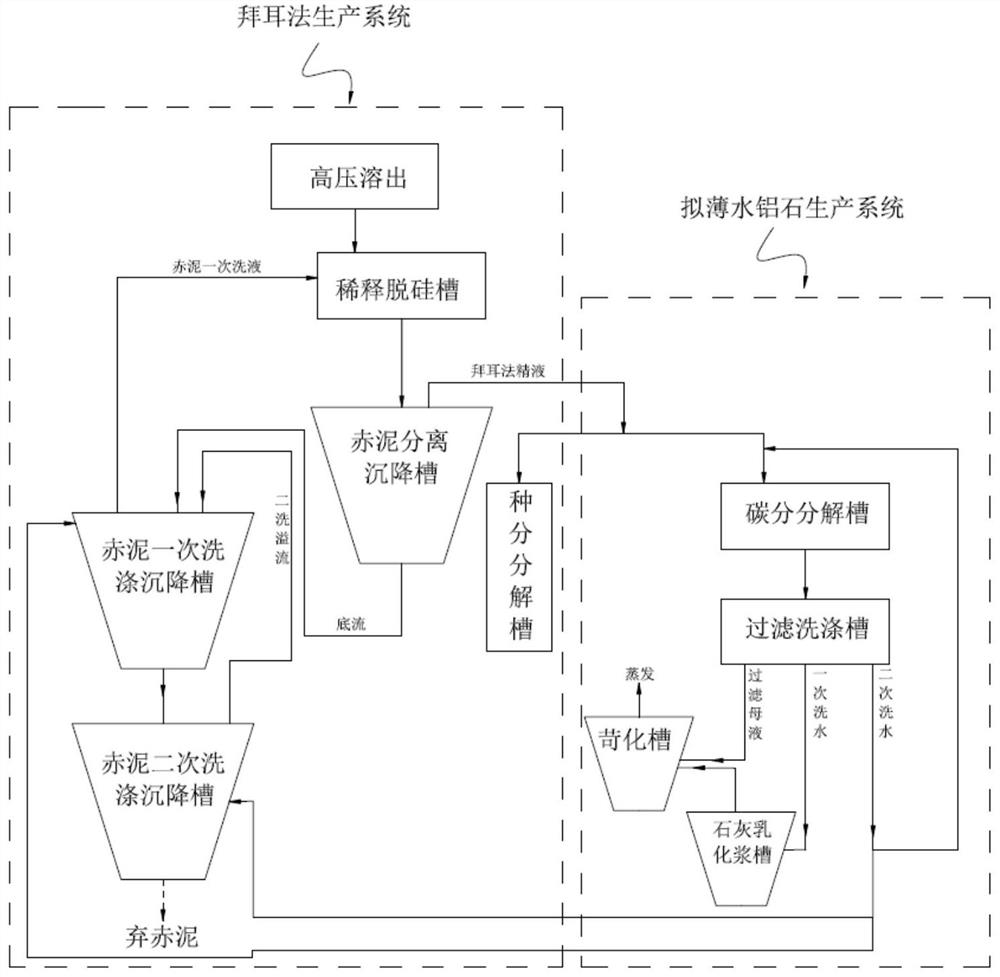

[0024] A alumina production enterprise A, according to figure 1 The process flow shown is produced. Process parameters are as follows:

[0025] Dissolved slurry: 200M 3 / h, NK 260g / L, αk 1.41, red mud A / S1.21;

[0026] Red mud, washing liquid: NK 58g / L, αk 1.59, 180m 3 / h;

[0027] Dilution dearse tank: NK 165g / L, αk 1.45;

[0028] Red Music Separation Substanting Coverter: NK 166G / L, αk 1.55;

[0029] Abandon Red Mud: A / S1.25;

[0030] Bayer method: αk 1.48.

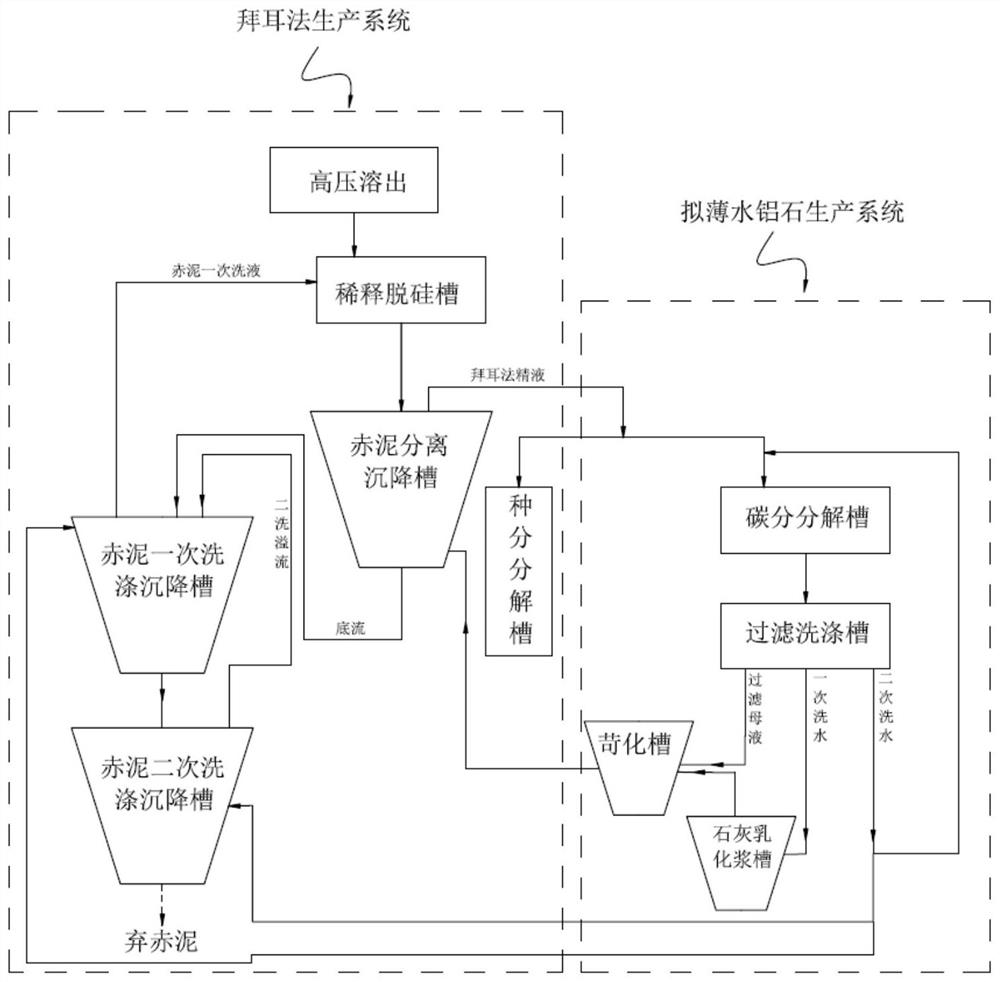

[0031] According to the method of the present invention, improved process flow charts image 3 As shown, the specific improvement is as follows:

[0032] The filtration of the filtration after the carbon fraction in the proposed thin aluminum stone production system is causing the lime millet to NK is 21 g / L, obtain a caustic liquid, and then send the caustic liquid to the mud layer of the sink groove. The lower part, 40m is added at 5 3 / h, after the red mud bottom flow of the sink groove, the red mud is was...

Embodiment 2

[0045] A alumina production enterprise B, according to figure 1 The process flow shown is produced. Process parameters are as follows:

[0046] Dissolved slurry: 320M 3 / h, NK 280g / L, αk 1.38, red mud A / S1.18;

[0047] Red mud once washing liquid: NK 61g / L, αk 1.57, 300m 3 / h;

[0048] Dilution dearse tank slurry: NK 168G / L, αk 1.42;

[0049] Red mud separation sink bottom ripple: NK 165g / L, αk 1.53;

[0050] Abandoning red mud: A / S1.21;

[0051] Bayer method: αk 1.45.

[0052] According to the method of the present invention, improved process flow charts image 3 As shown, the specific improvement is as follows:

[0053] The filtration of the filtration of the carbon sub-production system in a thin water aluminum stone production system is causing lime milings to 50 g / L to obtain a caustic solution. After the caustic liquid is supplied to the mud layer of the sink groove. A caustic solution 60m is added at 6 3 / h, after the red mud bottom flow of the sink groove, ...

Embodiment 3

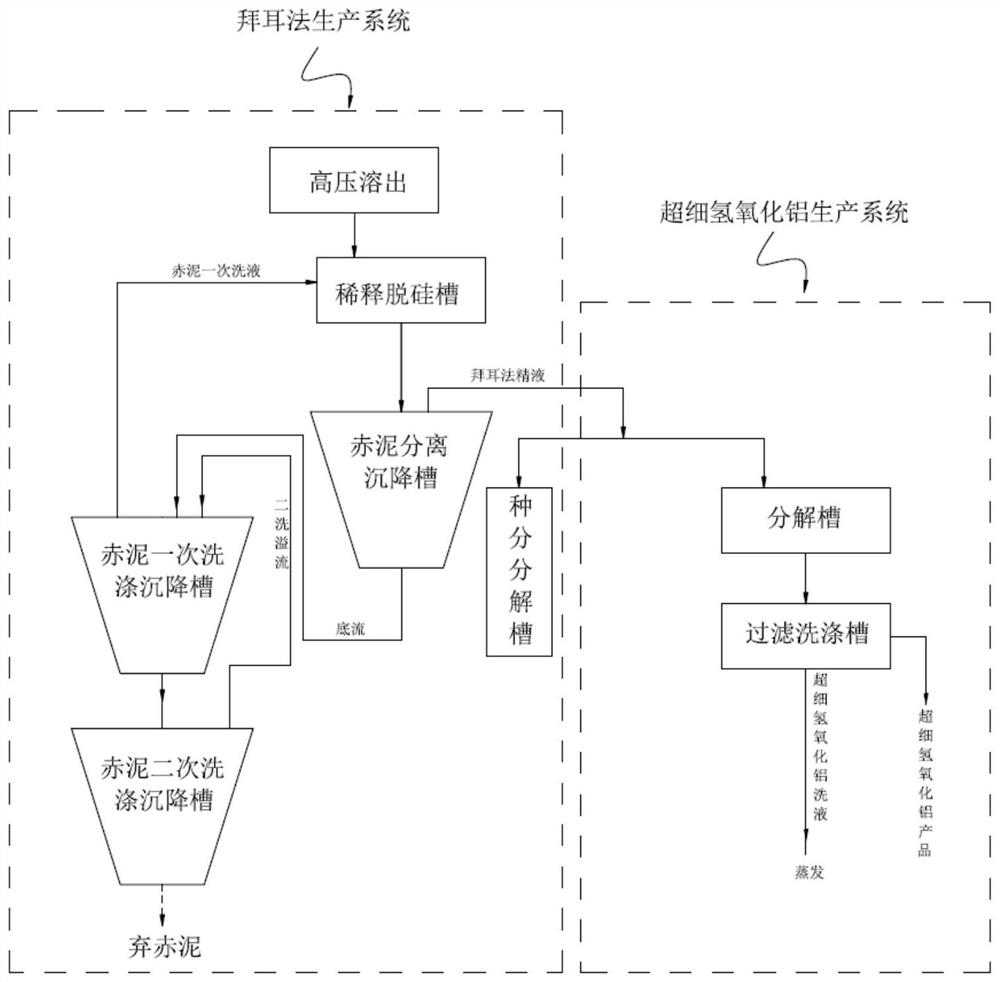

[0062] A alumina production company C, according to figure 2 The process flow shown is produced. The parameters are as follows:

[0063] Ultrafine hydroxide washing liquid: NK 60g / L, αk 2.95, 80m 3 / h;

[0064] Dissolved slurry: 520M 3 / h, NK 280g / L, αk 1.38, red mud A / S1.20;

[0065] Red mud once washing liquid: NK 61g / L, αk 1.57, 300m 3 / h;

[0066] Dilution dexerel tank: NK 165g / L, αk 1.40;

[0067] Red mud separation sink bottom ripple: NK 165g / L, αk 1.53;

[0068] Abandoning red mud: A / S1.23;

[0069] Bayer method semen: αk 1.46.

[0070] According to the method of the present invention, improved process flow charts Figure 4 As shown, the specific improvement is as follows:

[0071] The ultrafine hydroxide production system in the ultrafine hydroxide production system is sent to the middle and lower part of the mud layer of the sinking groove, and an ultrafine hydroxide washing liquid is added to 80m. 3 / h, after the red mud bottom flow of the sink groove, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com