Modular atomic force microscope

An atomic force microscope and modular technology, applied in scanning probe microscopy, instruments, surface/boundary effects, etc., can solve problems such as poor linearity, inconvenient adjustment and replacement, and decreased resonance frequency of scanners, etc., to achieve Effect of High Resonance Frequency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

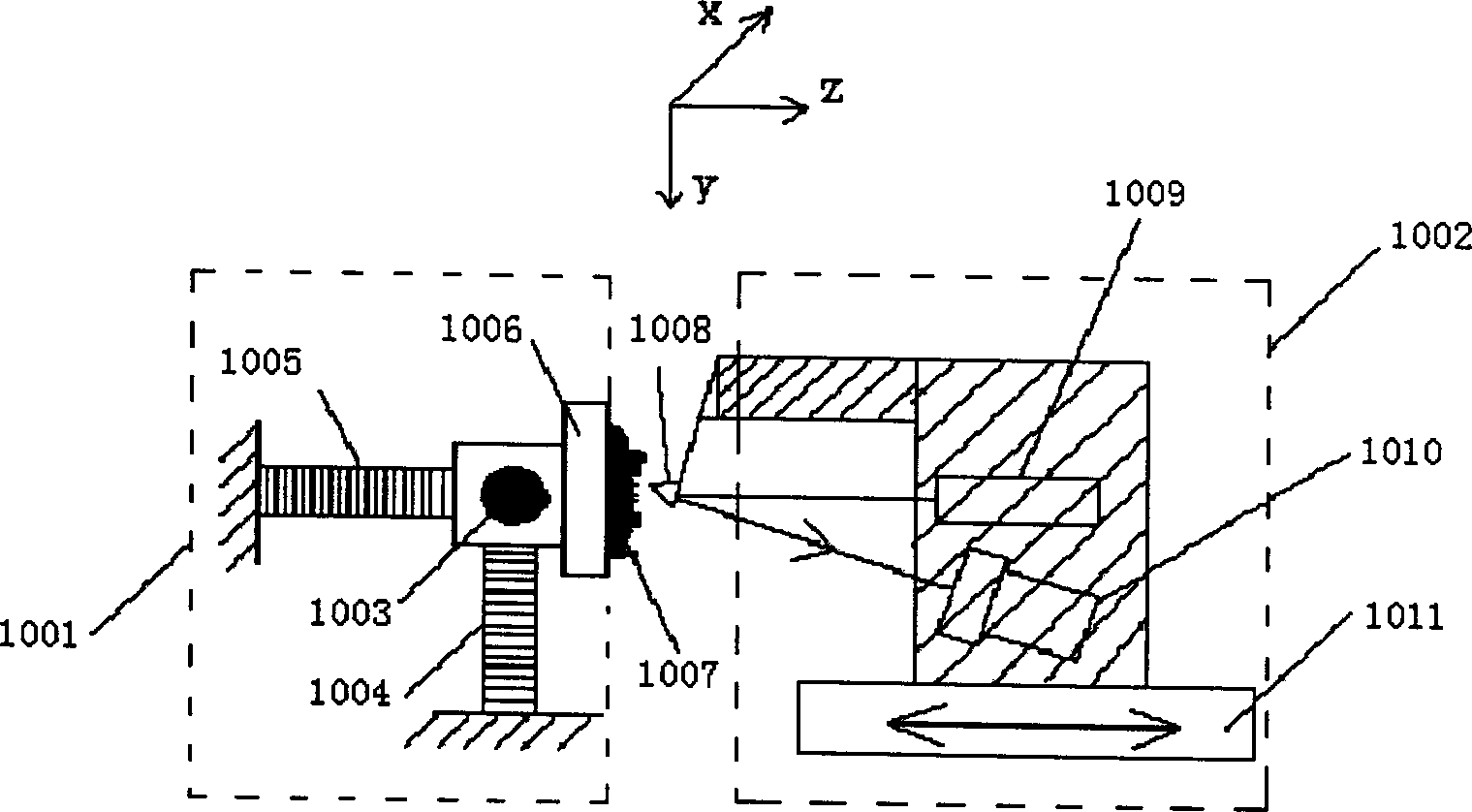

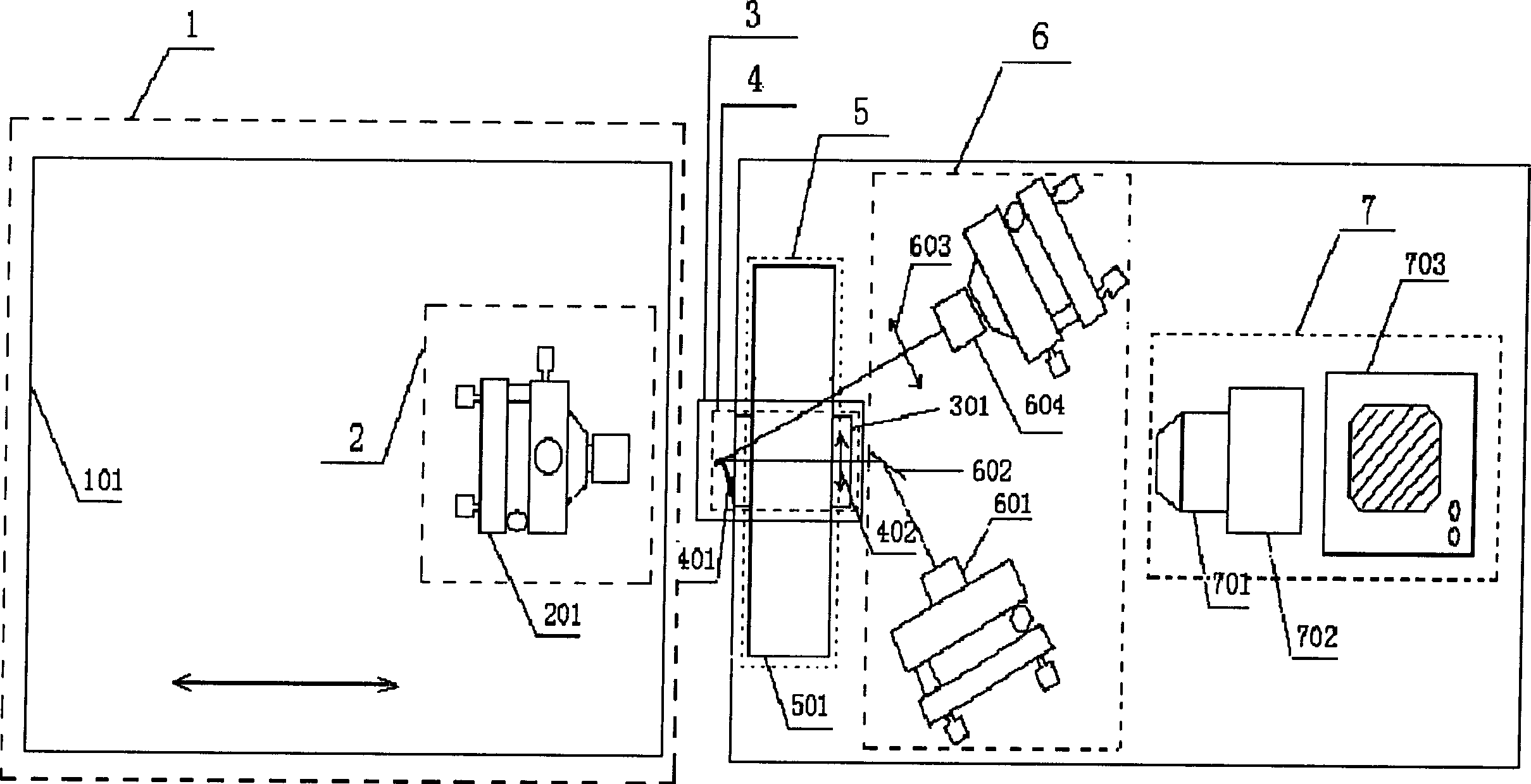

[0027]Embodiment 1 is a horizontal needle tip scanning atomic force microscope. The stepper motor 101 of module 1 adopts the M-405.DG linear displacement platform of PI Company, and its one-way repeatability accuracy is 200nm; As a rough positioning device for the sample, it can adjust the tilt, elevation and movement of the sample in the three directions of xyz; module 3 is the z-direction scanner 301, which uses the P-753.11C linear PZT platform actuator of PI company, The telescopic length is 0.012mm, and the unloaded resonant frequency is 5.6KHz; module 4 includes a microcantilever needle tip 401 with a horizontal tilt of 15 degrees and a focusing lens 402 with a focal length of 20mm, and module 4 is fixed on module 3; module 5 is an xy-direction scanner 501 adopts the P-734.2Cl type device of PI company, the scanning range is 0.1mm*0.1mm, the center of which is a 5cm*5cm light hole, and the no-load resonance frequency is 500Hz. Module 3 is fixed on module 5 and scans in ...

Embodiment 2

[0028] The principle of embodiment 2 is shown as image 3 As shown, using the above-mentioned modules, only the fifth module 5 is fixed on the first module 1, the sample is placed on the scanner of the fifth module 5, and the atomic force microscope with sample scanning tip feedback is formed by removing the second module. The microscope can be a reflection type in which the illumination light is irradiated from the top of the sample, or a projection type in which the illumination light is irradiated from the bottom of the sample, because the scanner of the module 5 has a light hole.

Embodiment 3

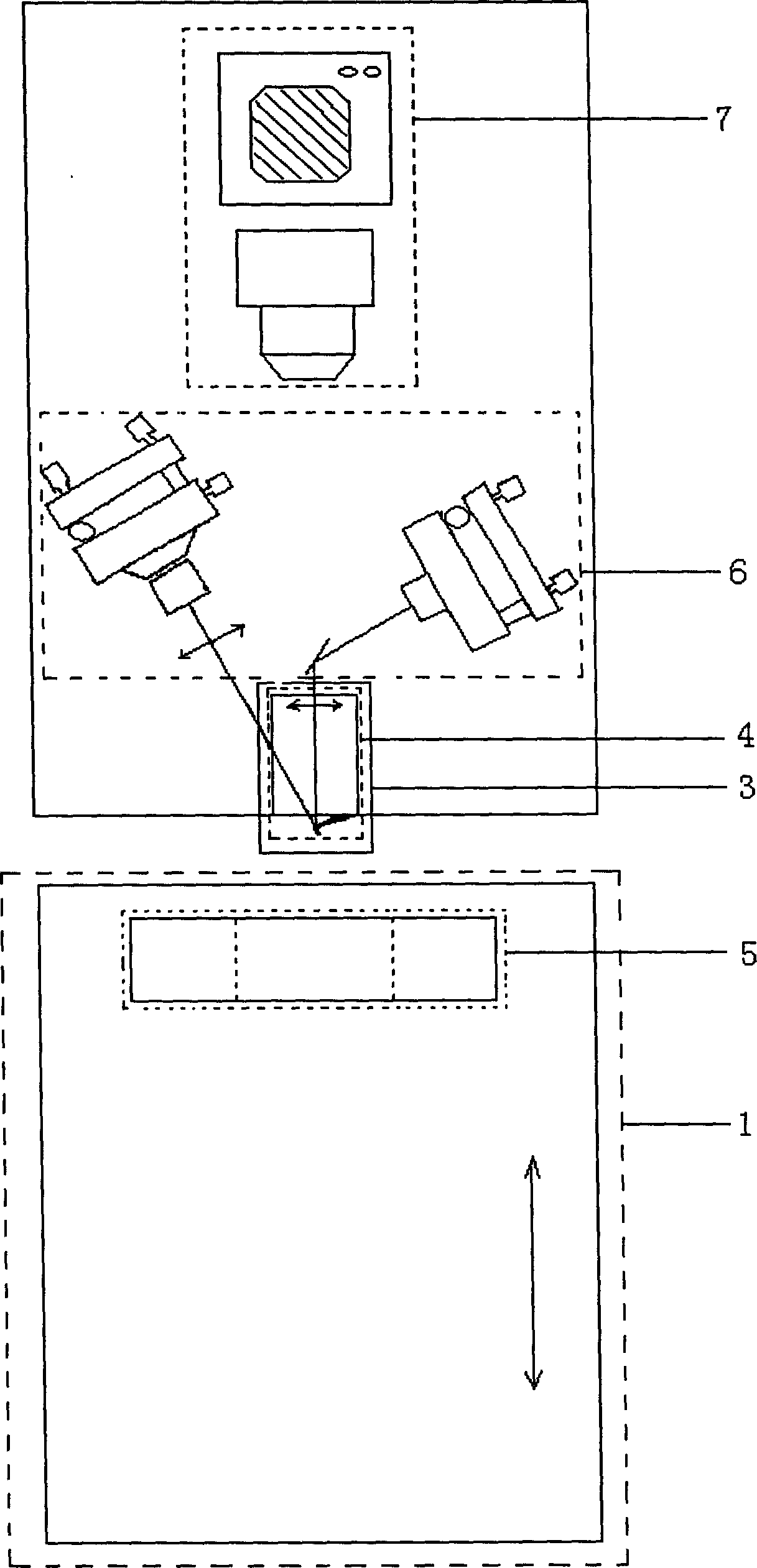

[0029] The principle schematic diagram of embodiment 3 is as Figure 4 As shown, using the above-mentioned modules, just place the sample on the scanner of the fifth module 5, and the first module 1 drives the third module 3, the fourth module 4, and the sixth module 6 to approach the sample from top to bottom , the seventh module 7 is fixed directly above the sample and the needle point with another shelf, and the whole adopts a vertical structure.

[0030] Proved by experiments, the present invention has the following advantages:

[0031] 1. The modular atomic force microscope of the present invention adopts two independent devices separated by xy scanning and z scanning, which can better ensure the orthogonality of scanning motion in the three directions of xyz; the xy direction scanner and the z direction scanner both With a position sensor, the use of a closed-loop feedback loop for the scanner's controller can well ensure a linear relationship between the scanner's inpu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com