Method for producing beer

A technology for beer and porous membranes, applied in the field of filtering beer through filter media and cleaning filter media with enzymes, can solve the problems that the filter cannot be cleaned satisfactorily, the service life of the filter is shortened, and the cleaning is too early or too late

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

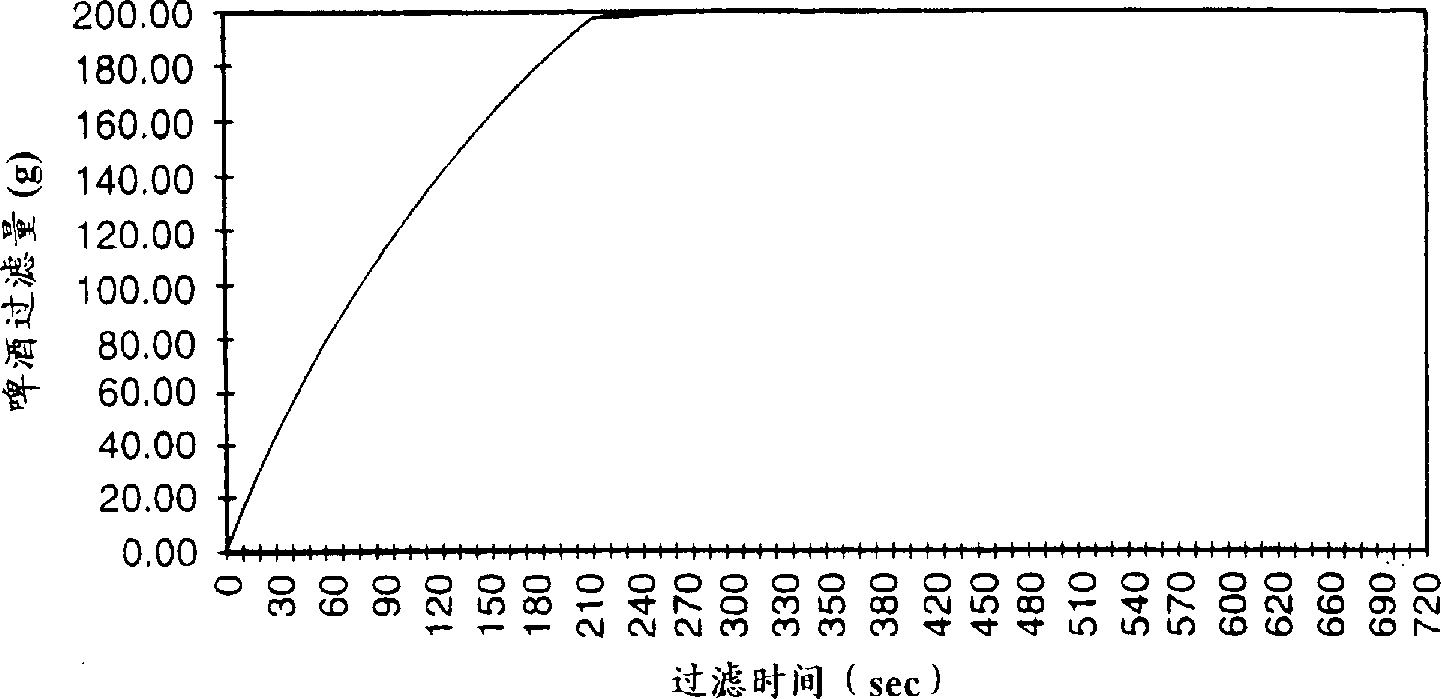

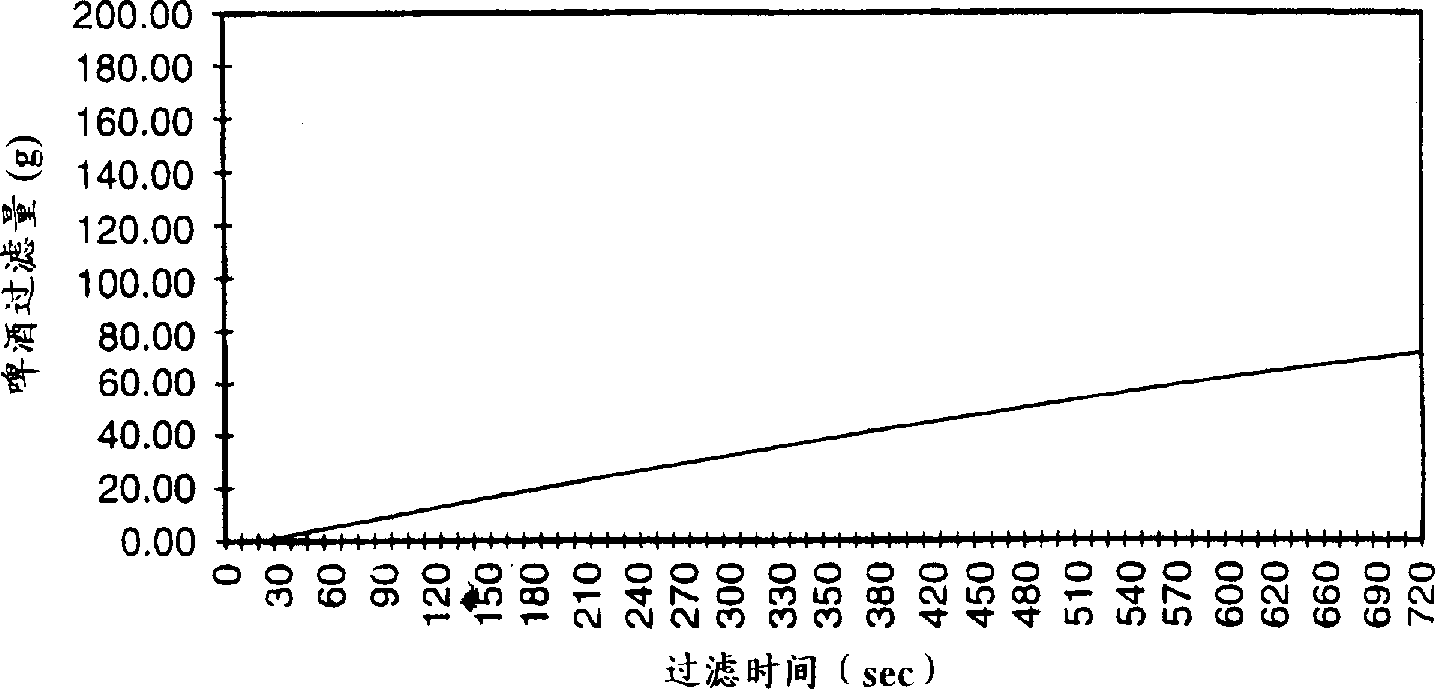

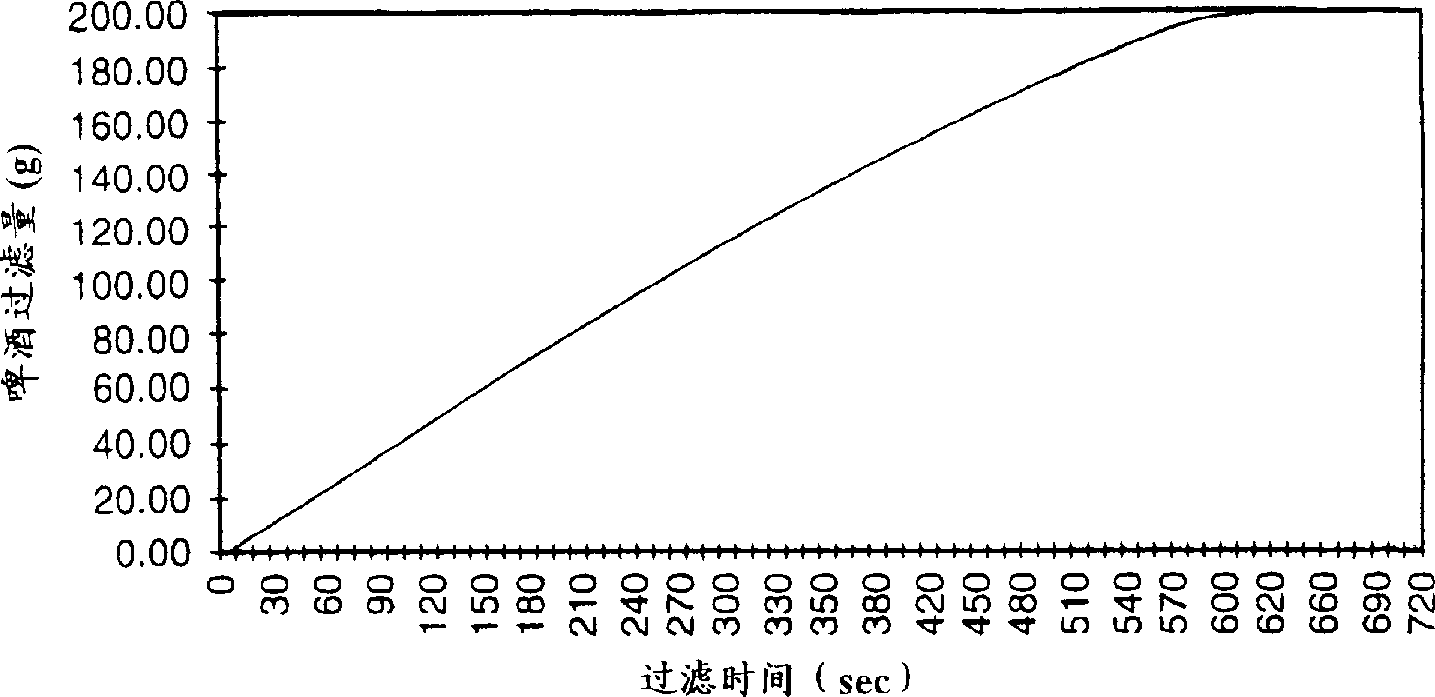

[0053] This example illustrates the effectiveness of the method of the present invention for producing beer. In particular this example demonstrates that cellulases and amylases can be used to clean porous membranes clogged during beer filtration satisfactorily, enabling reuse of the porous membranes for continued beer filtration.

[0054] A porous membrane made of nylon-6,6 (NB type, manufacturer: Pall Filtrationstechnik GmbH, Germany) was used as a filter. This kind of filter is often used under the process conditions of low temperature filtration of beer.

[0055] The filtration performance of the filter was determined using the so-called membrane filter test according to Esser (Monatszeitschrift für Brauerei (Monthly magazine for breweries), 25th year, No. 6, pp. 145-151, 1972). This test is used to check the extent to which the filtration capacity is increased is reliable.

[0056] In order to determine the filtration efficiency of new, that is, unused porous membranes,...

Embodiment 2

[0069] This example is to illustrate the promotion effect of the efflux potential or zeta potential of the porous membrane on the cleaning of the porous membrane. In particular, it was demonstrated that using the efflux potential or zeta potential can accurately determine how well the membrane has been cleaned and when the membrane has been cleaned to a very satisfactory level.

[0070] The zeta potential of the membrane filter was determined using an electrokinetic measuring device EKA from Anton Paar GmbH, Austria. This assay is based on the efflux potential method. An electrolyte is passed through the filter, and the potential generated by the shearing action on the counterion (efflux potential) is detected by electrodes, and the zeta potential is calculated from the measured value.

[0071] Figure 5 Diagram showing the measuring cell for measuring the efflux potential or zeta potential. Reference numeral 1 denotes a measuring cell in which a porous membrane 2 is sandwi...

Embodiment 3

[0088] This example illustrates the effectiveness of cellulase from Aspergillus niger in the enzymatic breakdown of soluble and crystalline cellulosic substrates.

[0089] Cellulase from Aspergillus niger (Product No. 22178) was obtained from Fluka. Two different celluloses were used to evaluate the enzyme: soluble carboxymethylcellulose (CMC, commercially available from Aldrich as product number 41927-3) and crystalline cellulose (Avicel, commercially available as product number PH-105 from purchased by FMC).

[0090] The test method includes preparation of culture medium (i) 18ml of CMC (1%) or Avicel (1%), (ii) 5ml of sodium acetate buffer (50mM, pH4.8), and (iii) preparation of 5ml in acetic acid at 30°C The enzyme solution in sodium buffer (50 mM, pH 4.8). Then 1.4 ml of culture broth, 0.1 ml of glucose solution (0.15%) and 1.5 ml of 3,5-dinitrosalicylic acid (DNS) reagent (purchased from Sigma under product number D-0550) were mixed to prepare a test solution. The tes...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com