Method for extracting sweet potato dietary fibers

A sweet potato dietary fiber and extraction method technology, applied in the field of bioengineering, can solve the problems of loss of resistant starch, low product purity, high cost, etc., achieve the effect of solving processing problems, good functional indicators, and improving productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

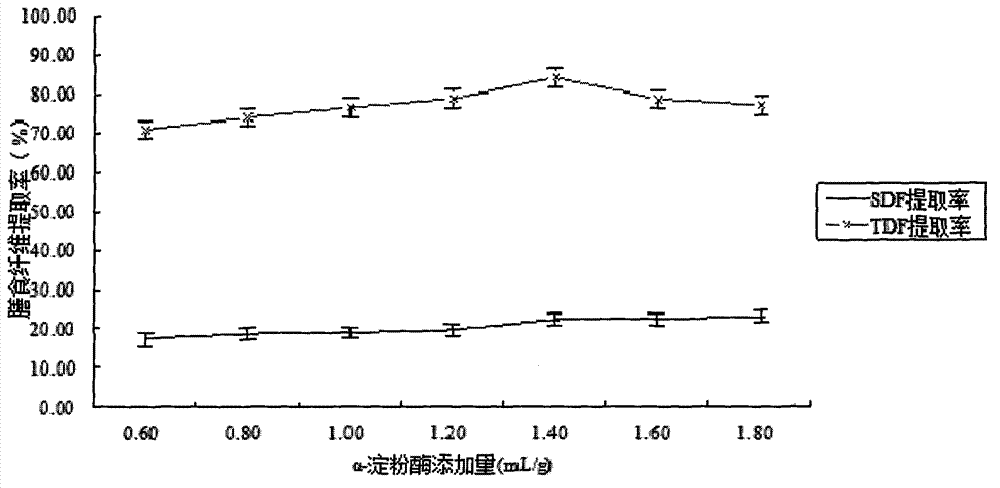

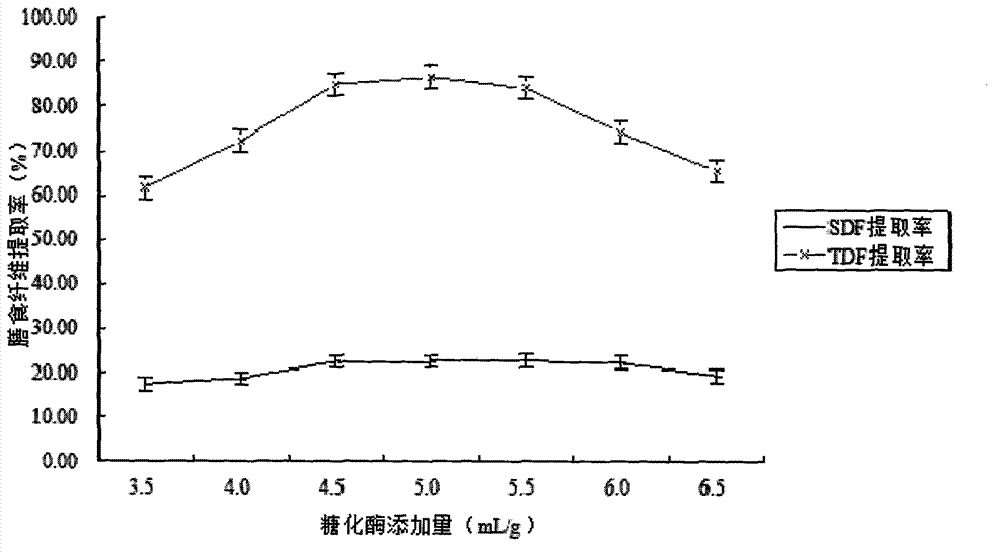

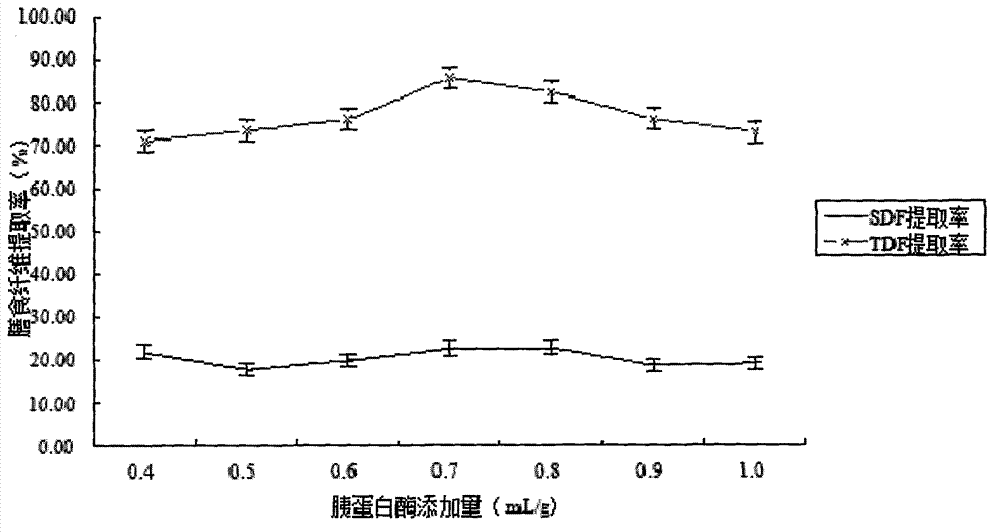

Image

Examples

Embodiment Construction

[0038] The present invention will be further described below in conjunction with specific embodiment:

[0039] A method for extracting sweet potato dietary fiber, comprising: removing starch, enzymatic hydrolysis, centrifuging and extracting dietary fiber, said extracting dietary fiber includes extracting insoluble dietary fiber and extracting soluble dietary fiber;

[0040] Extraction of insoluble dietary fiber: Centrifuge the mixed solution after enzymolysis to obtain mutually separated precipitates and supernatants, soak the obtained precipitates in ethanol solution, and then undergo suction filtration to obtain solids and filtrates; the obtained solids Insoluble dietary fiber;

[0041] Extract soluble dietary fiber: The supernatant and filtrate obtained in the above process are evaporated most of the water in a water bath, and then add 95% ethanol solution for leaching. At this time, flocculent precipitates appear in the supernatant and filtrate. The supernatant and the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com