Fly ash concrete light weight multi-porous ribbon board and manufacturing method thereof

A manufacturing method and technology of fly ash, applied in the direction of manufacturing tools, building structures, building components, etc., can solve the problems of easy shrinkage cracks, increased drying shrinkage value, and poor carbonization resistance of boards, so as to achieve beneficial benefits Waste and environmental protection requirements, increase the strength and compactness of concrete, and improve the effect of anti-carbonization performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

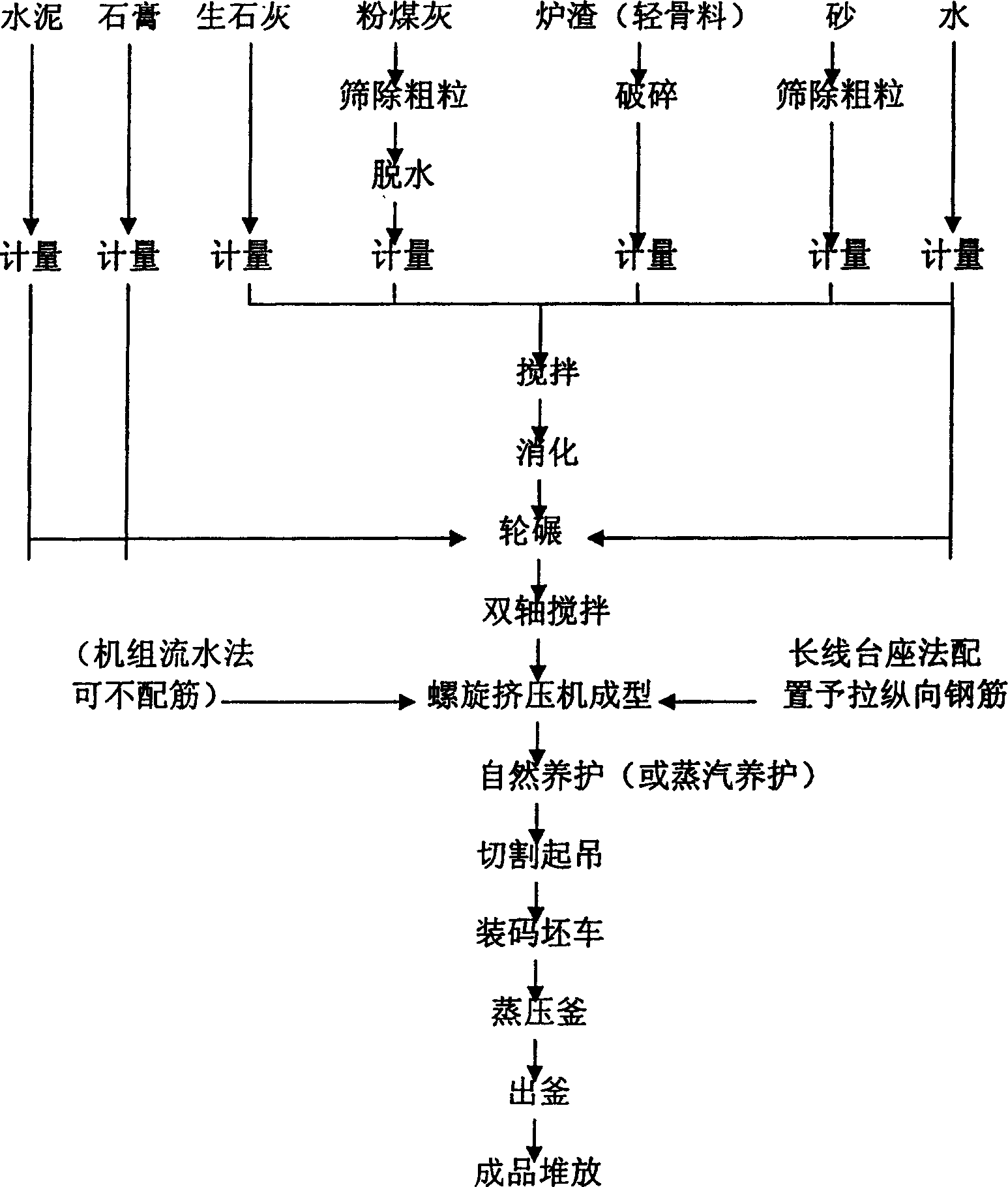

[0099] Such as figure 1 As shown, the long-line pedestal method is used to extrude the lightweight porous slab of fly ash concrete with a mixture of 1000 kg: take the fly ash containing SiO 2 46.5%, quicklime contains CaO65%, cement is ordinary portland cement 42.5 # . Its manufacturing steps are as follows:

[0100] Step 1: According to the early strength requirements of the board, add 15% cement, and design ingredients according to C / S=0.25:

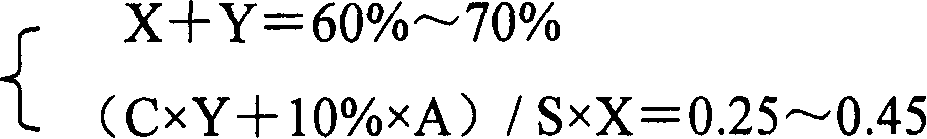

[0101] Set the amount of fly ash X and the amount of lime Y, and establish the calculation formula:

[0102] X + Y = 60 % ( C × Y + 10 % × A ) ...

Embodiment 2

[0115] Such as figure 1 As shown, the long-line pedestal method is used to extrude the lightweight porous slab of fly ash concrete with a mixture of 1000 kg: take the fly ash containing SiO 2 46.5%, lime contains CaO65%, cement is ordinary portland cement 42.5 # .

[0116] Step 1: According to the early strength requirements of the board, mix 23% of cement, and design the ingredients according to C / S=0.45:

[0117] Set the amount of fly ash X and the amount of lime Y, and establish the calculation formula:

[0118] X + Y = 65 % ( C × Y + 10 % × A ) / S ...

Embodiment 3

[0131] Such as figure 1 As shown, the lightweight porous slab of fly ash concrete with a mixture of 1000 kg is extruded by the flow method of the unit: take the fly ash containing SiO 2 46.5%, lime contains CaO65%, cement is ordinary portland cement 42.5 # .

[0132] Step 1: According to the early strength requirements of the board, add 15% cement, design the ingredients according to C / S=0.35, set the amount of fly ash X and the amount of lime Y, and establish the calculation formula:

[0133] X + Y = 65 % ( C × Y + 10 % × A ) / S × ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com