Parallel array-type small refrigerator and production thereof

A refrigerator and array-type technology, which is applied in the direction of refrigerators, refrigeration and liquefaction, and machine operation methods, can solve the problems of device separation, limit the working efficiency of devices, and large surface contact resistance, so as to improve the yield and work efficiency. Stability, the effect of reducing the interface contact resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

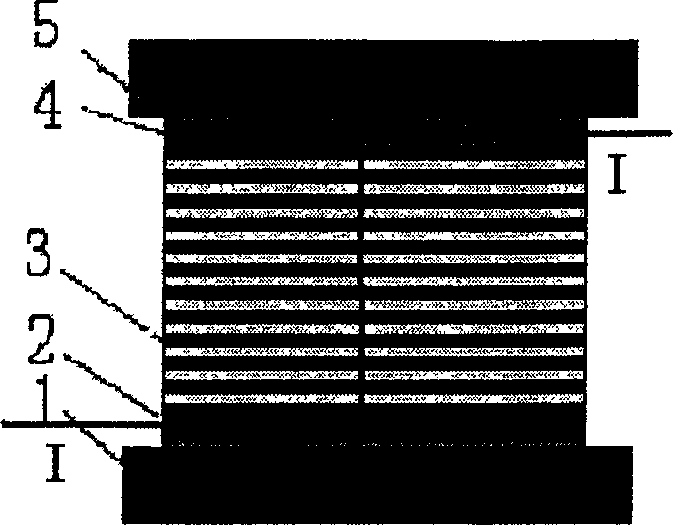

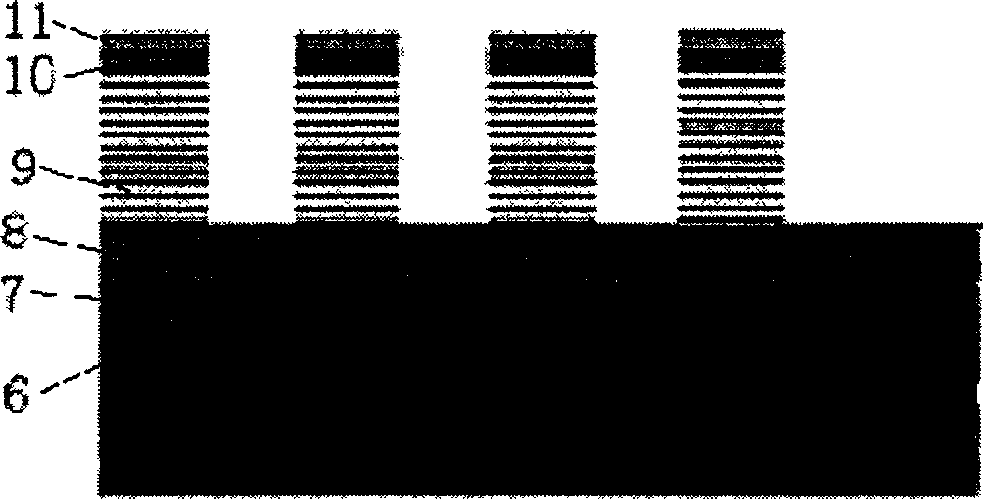

[0031] The invention intends to use the oxide isolation process to form a parallel array micro refrigerator.

[0032] The silicon germanium superlattice material in the III-V semiconductor material or the IV semiconductor material is used, and the multi-stage refrigerator is isolated by a silicon dioxide film to form a parallel array micro refrigerator.

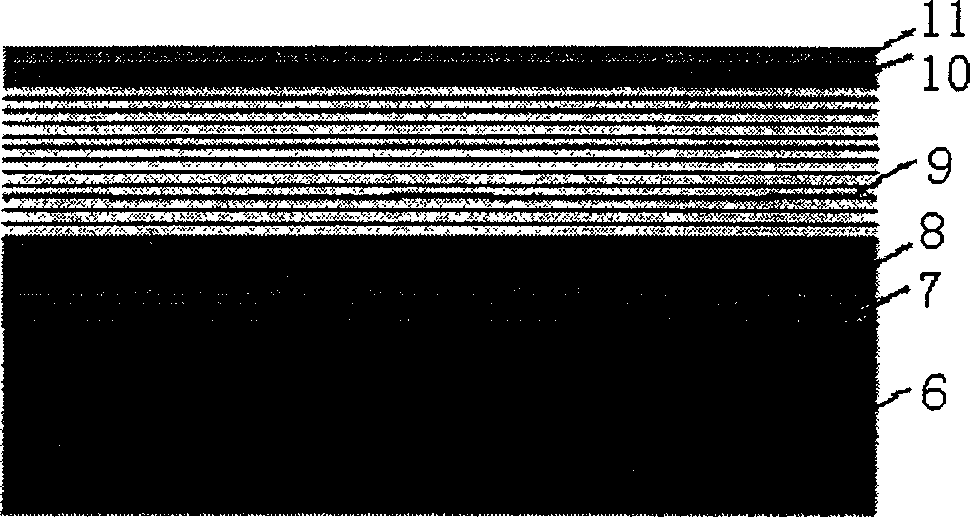

[0033] The structure of the microrefrigerator is a layered structure, and its layered positions are arranged in order: the silicon substrate (6) of the P-type semiconductor, the buffer layer (7) of the P-type semiconductor, and the first heavily doped layer of the P-type semiconductor ( 8), the superlattice layer (9) of the P-type semiconductor, the second heavily doped layer (10) of the P-type semiconductor, the third heavily doped layer (11) of the P-type semiconductor, and the metal layer (13); two The silicon oxide isolation layer (12) is located between the P-type semiconductors and between the metal layer and the first ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com