Method of extracting soyabean isoflavone and soya bean saponin for soya bean whey waste water

A technology of soybean whey wastewater and soybean isoflavones, which is applied in chemical instruments and methods, preparation of sugar derivatives, sugar derivatives, etc., can solve the problems of single material recovery, complex process, high cost, etc., and achieve simple process and broad market Prospect, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

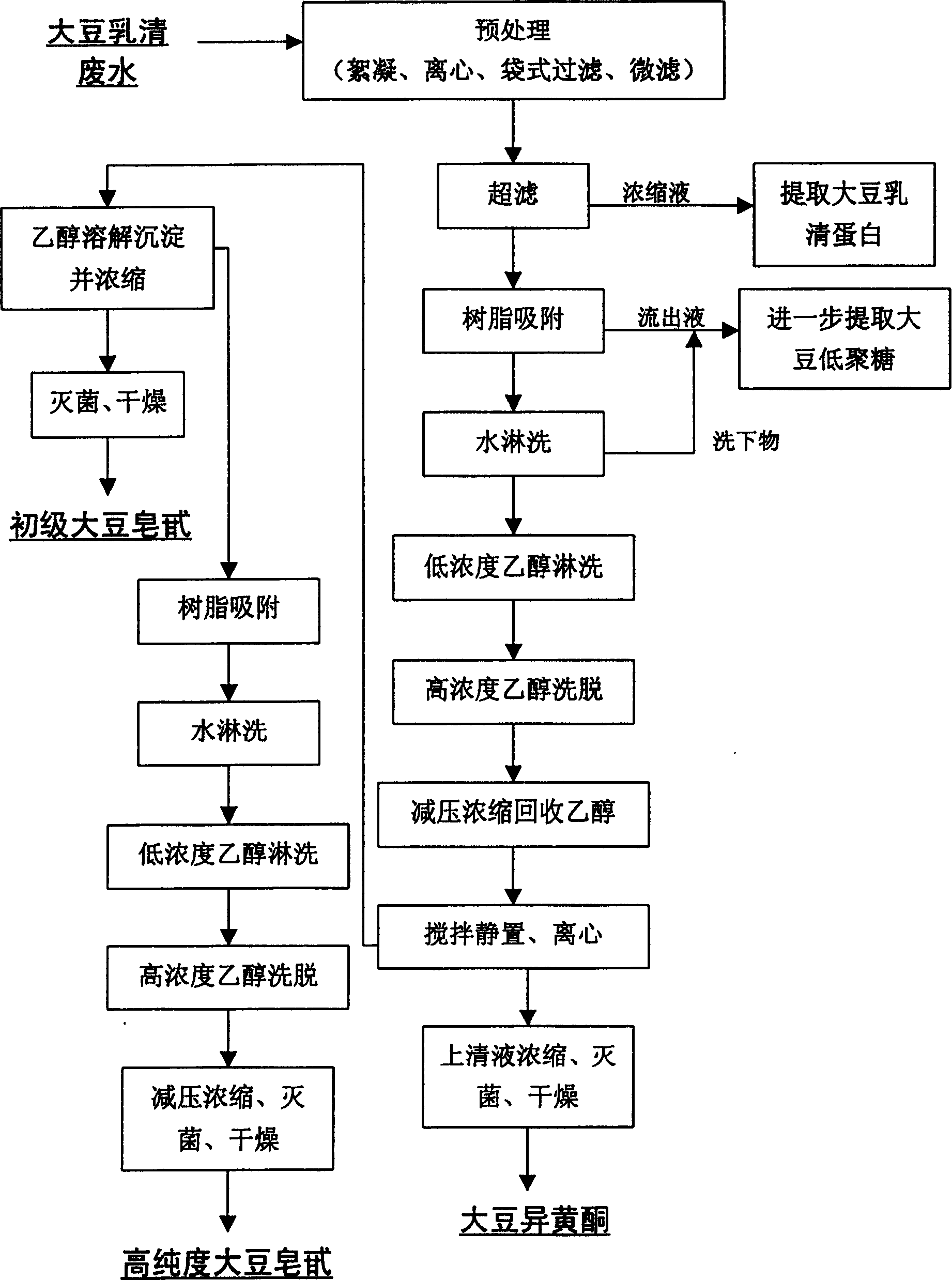

[0038] Embodiment one, refer to figure 1 :

[0039] ① Pretreatment:

[0040] a) Put the soybean whey wastewater obtained by producing soybean protein isolate by one-step alkali-dissolving and acid-precipitating process into a flocculation tank, and carry out flocculation and centrifugation by adjusting the pH value and adding electrolytes. b) Filtrating the flocculation centrifugate through a bag filter and a microfilter to obtain a microfiltration permeate A1. c) concentrating the microfiltration permeate A1 through an ultrafiltration device to obtain ultrafiltration permeate B1 and ultrafiltration concentrate C1.

[0041] ②Resin series adsorption recovery of soybean isoflavones and soybean saponins:

[0042] a) The ultrafiltration permeate B1 is passed through the series resin column of different weakly polar macroporous adsorption resin columns X1 and X2 at a flow rate of 1.5BV / h to obtain the effluent D1, wherein the volume of the ultrafiltration permeate B1 is equal to...

Embodiment 2

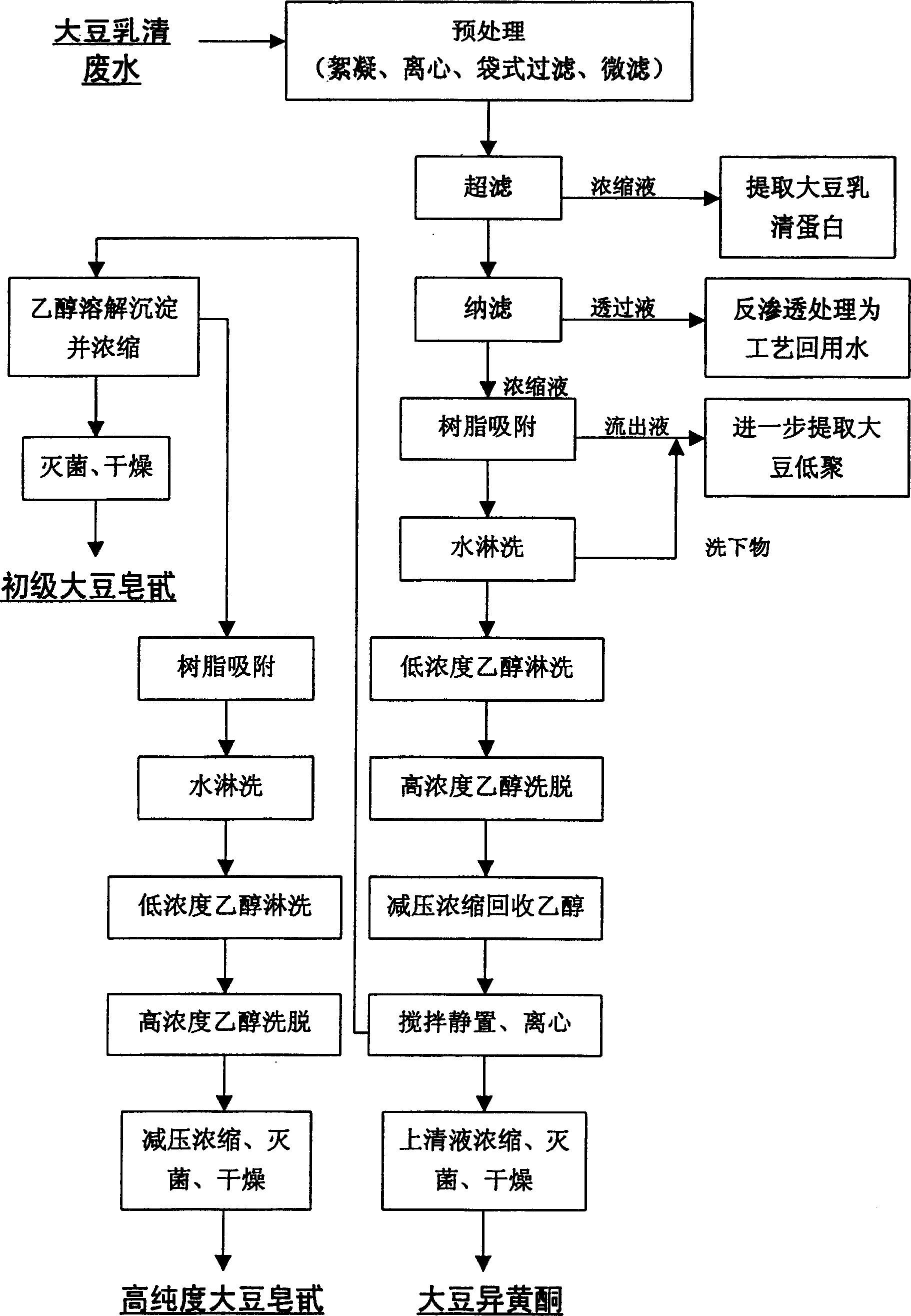

[0049] Embodiment two, refer to figure 2 :

[0050] ① Pretreatment:

[0051] a) Put the soybean whey wastewater obtained by producing soybean protein isolate by one-step alkali-dissolving and acid-precipitating process into a flocculation tank, and carry out flocculation and centrifugation by adjusting the pH value and adding electrolytes. b) Filtrating the flocculation centrifugate through a bag filter and a microfilter to obtain a microfiltration permeate A2. c) concentrating the microfiltration permeate A2 through an ultrafiltration device to obtain ultrafiltration permeate B2 and ultrafiltration concentrate C2. d) Concentrating the ultrafiltration permeate B2 through a nanofiltration device to obtain nanofiltration permeate N-F and nanofiltration concentrate D-C.

[0052] ②Resin series adsorption recovery of soybean isoflavones and soybean saponins:

[0053] a) Add pure water equivalent to twice its volume to the nanofiltration concentrated solution D-C to obtain the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com