Method for signal implant in making processing of mask type read-only memory

A read-only memory and manufacturing process technology, which is applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve the problems of limited device size, low yield, and easy peeling of photoresist masks, so as to increase output, Overcomes the effect of falling off easily

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

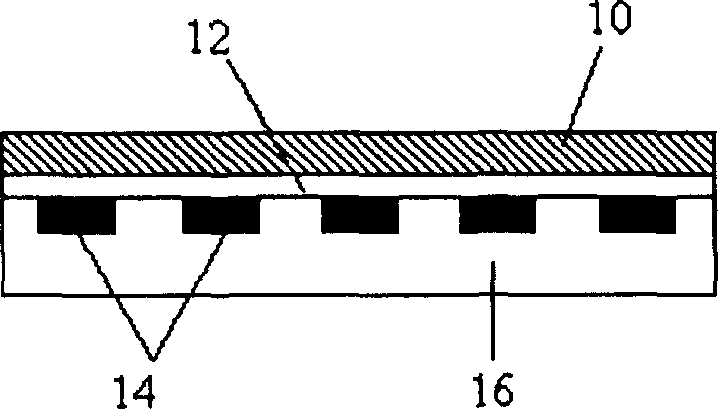

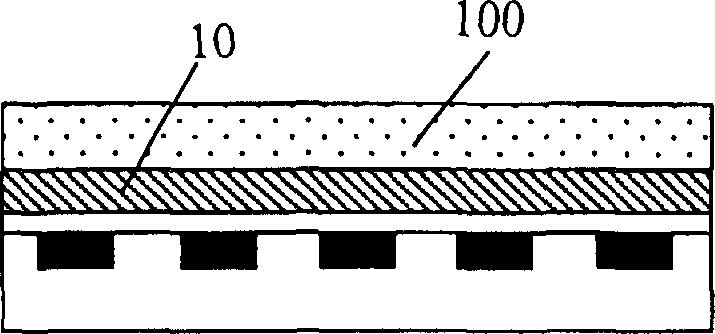

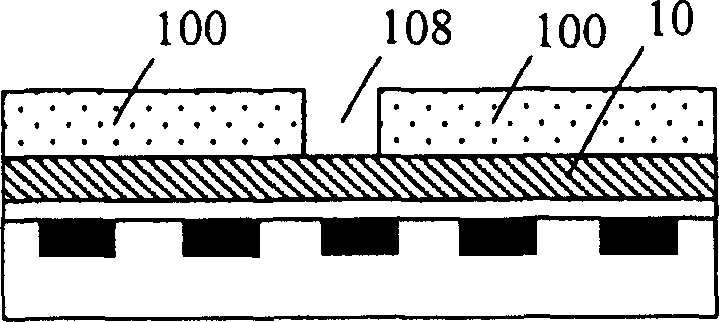

[0029] Figure 1A-Figure 1I A particularly preferred embodiment of the invention is shown. In this embodiment, signal injection is performed using a tungsten hard mask.

[0030] Such as Figure 1A As shown, after forming the MOS source region and the drain region and annealing, the p well (p well) 16 is located at the bottom of the substrate, the buried n+ (buried n-plus) 14 is located above the p well, and the gate oxide layer ( gate oxide) 12 is located above the p-well 16, and the gate 10 is located above the gate oxide layer 12.

[0031] In the first step, a layer of SiO is deposited on the gate 10 2 100, such as Figure 1B shown. Here, SiO 2 The thickness of the layer 100 can be determined according to the magnitude of the signal injection energy and the material used for the mask, for example, about 600 Ȧ. Moreover, it is best for SiO 2 The layer is planarized, for example by chemical mechanical polishing, which is preferably used in the present invention.

[00...

Embodiment 2

[0040] Figure 2A-Figure 2G A preferred embodiment of the invention is shown. In this example, using SiO 2 Hard mask for signal injection.

[0041] Such as Figure 2A As shown, after forming the MOS source and drain regions and annealing, the p well 16 is located at the bottom of the substrate, the buried n+14 is located above the p well, the gate oxide layer 12 is located above the p well 16, and the gate 10 is located on the gate oxide layer 12 .

[0042] In the first step, a layer of Si is deposited on the gate 10 3 N 4 120, such as Figure 2B shown. Here, Si 3 N 4 The thickness of the layer 120 can be determined according to the magnitude of signal injection energy and the material used for the mask, for example, about 2000 Ȧ. Moreover, it is best for Si 3 N 4Layer 120 is planarized, such as by chemical mechanical polishing, which is preferably employed in the present invention.

[0043] In the second step, use a pre-prepared mask to Si 3 N 4 Layer 120 is p...

Embodiment 3

[0049] Figure 3A-Figure 3G Another preferred embodiment of the invention is shown. In this example, using Si 3 N 4 Hard mask for signal injection. The step of embodiment three is basically the same as embodiment two, and its difference is: 140 is SiO 2 , 142 for Si 3 N 4 ; 148 is a hole pattern; 140 is etched using 10:1 HF.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com