Photocatalyst for treating waste water containing phenol and its preparation method

A photocatalyst and wastewater treatment technology, applied in the direction of physical/chemical process catalysts, catalyst carriers, chemical instruments and methods, etc., can solve the problems of reduced photocatalytic activity, difficult recycling, easy agglomeration, etc., to achieve simple preparation process, high ratio Good surface area and good repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

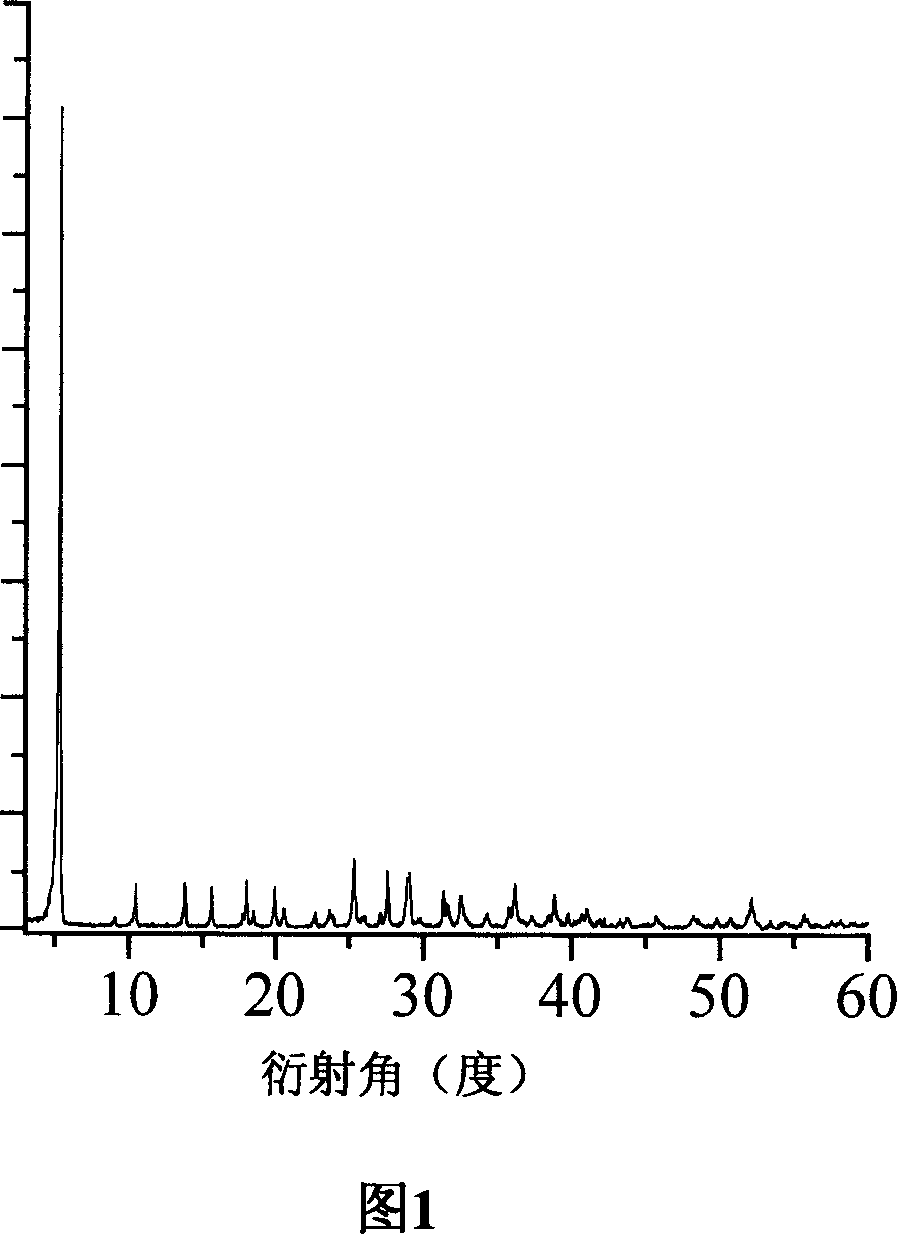

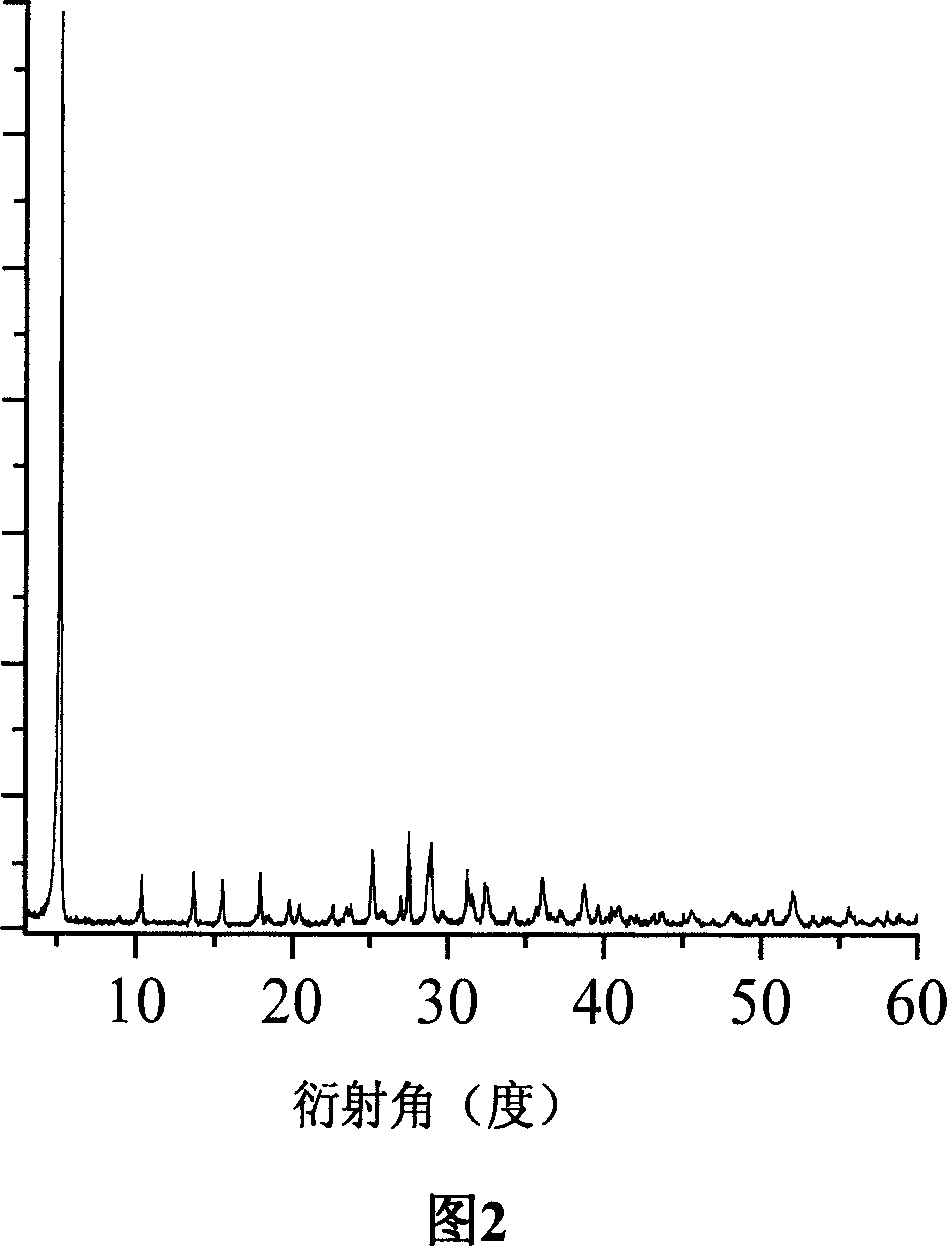

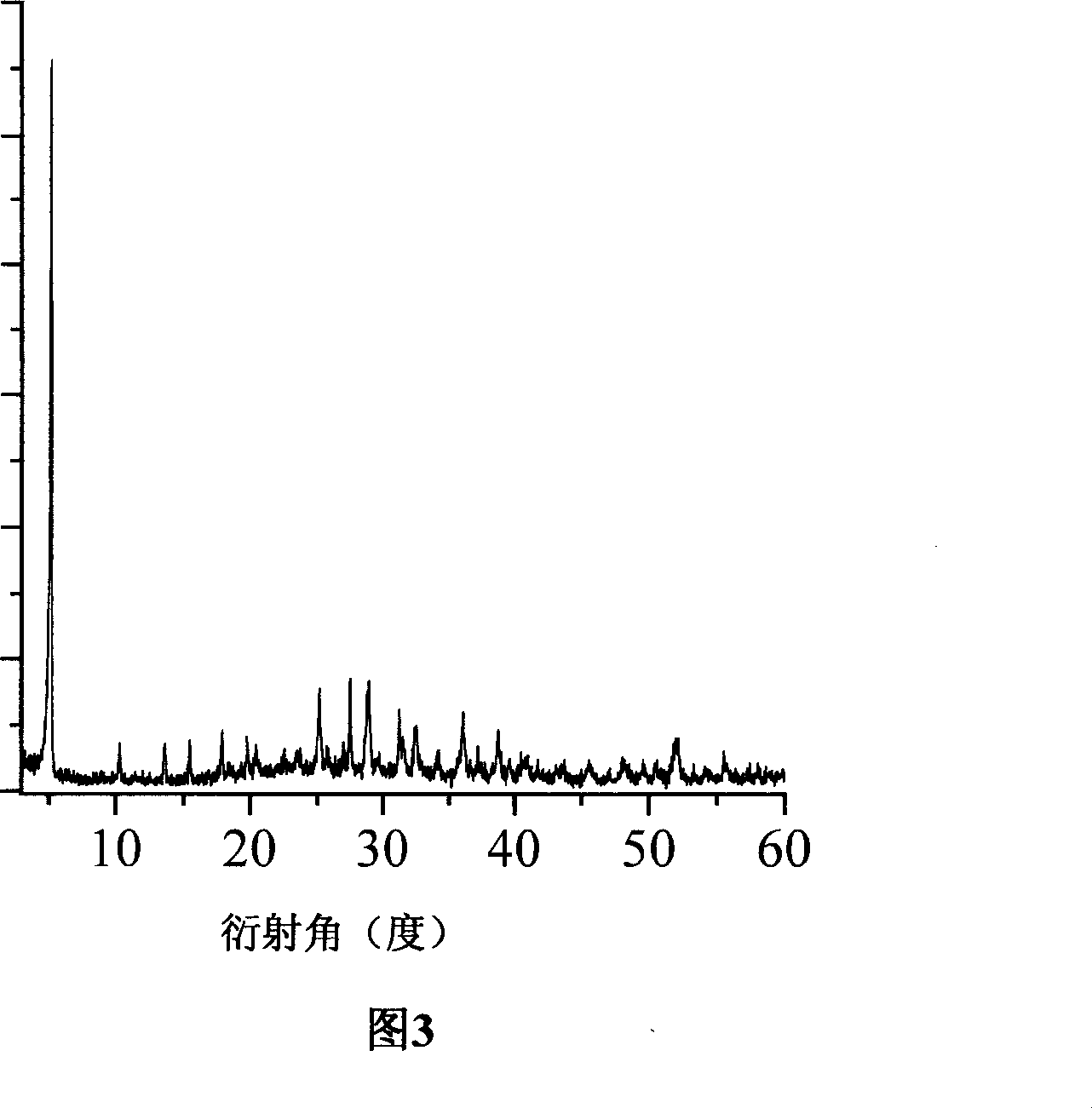

[0025] Example 1: Weigh 0.3 g of pre-synthesized VSB-1, and its X-ray diffraction is shown in FIG. 1 . The pore size distribution is 0.9-1.2nm. Added to the dry n-hexane solution containing n-butyl titanate, the resulting mixture was 2 Stir and reflux under protection for 24 hours, and the reaction temperature is 343K. The precipitate obtained after centrifugation was fully washed with dry anhydrous n-hexane solution to remove the butyl titanate that did not enter the micropores of nickel phosphate; the obtained solid was hydrolyzed by adding deionized water (Figure 3), and dried at 313K for 12 hours ; The dried solid product was roasted at 773K for 3 hours to obtain a brownish-yellow photocatalyst TiO 2 / VSB-1 (Figure 4), where TiO 2 The content is 1.23wt%. Weigh 0.2g of the photocatalyst TiO prepared above 2 / VSB-1 was added to a photocatalytic reaction vessel with 400ml of newly prepared phenol aqueous solution with a concentration of 50ppm, and the mixture was stirred...

Embodiment 2

[0026] Embodiment 2: Weigh and photocatalyst TiO 2 3 mg of pure amorphous TiO equivalent to the active ingredient in / VSB-1 2As a comparative experiment, it was added to 400ml of newly prepared aqueous phenol solution with a concentration of 50ppm. Reaction process and operation steps are with embodiment 1. When the reaction time was 2 hours, the degradation rate of phenol in the solution was only 36.54%. (Figure 5, curve b)

Embodiment 3

[0027] Embodiment 3: Weigh and photocatalyst TiO 2 3 mg of pure anatase TiO equivalent to the active component in / VSB-1 2 As a comparative experiment, it was added to 400ml of newly prepared aqueous phenol solution with a concentration of 50ppm. Reaction process and operation steps are with embodiment 2. When the reaction time was 2 hours, the degradation rate of phenol in the solution was only 16.80%. (Figure 5, curve c)

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com