Static electricity preventing device using flexible x-ray and method for making its flexible x-ray tubes

An anti-static and X-ray technology, applied in X-ray tubes, X-ray equipment, static electricity, etc., can solve the problems of long X-ray wavelength and poor thermal characteristics of X-ray generating devices, and achieve the purpose of suppressing heating temperature, small size, The effect of eliminating static electricity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

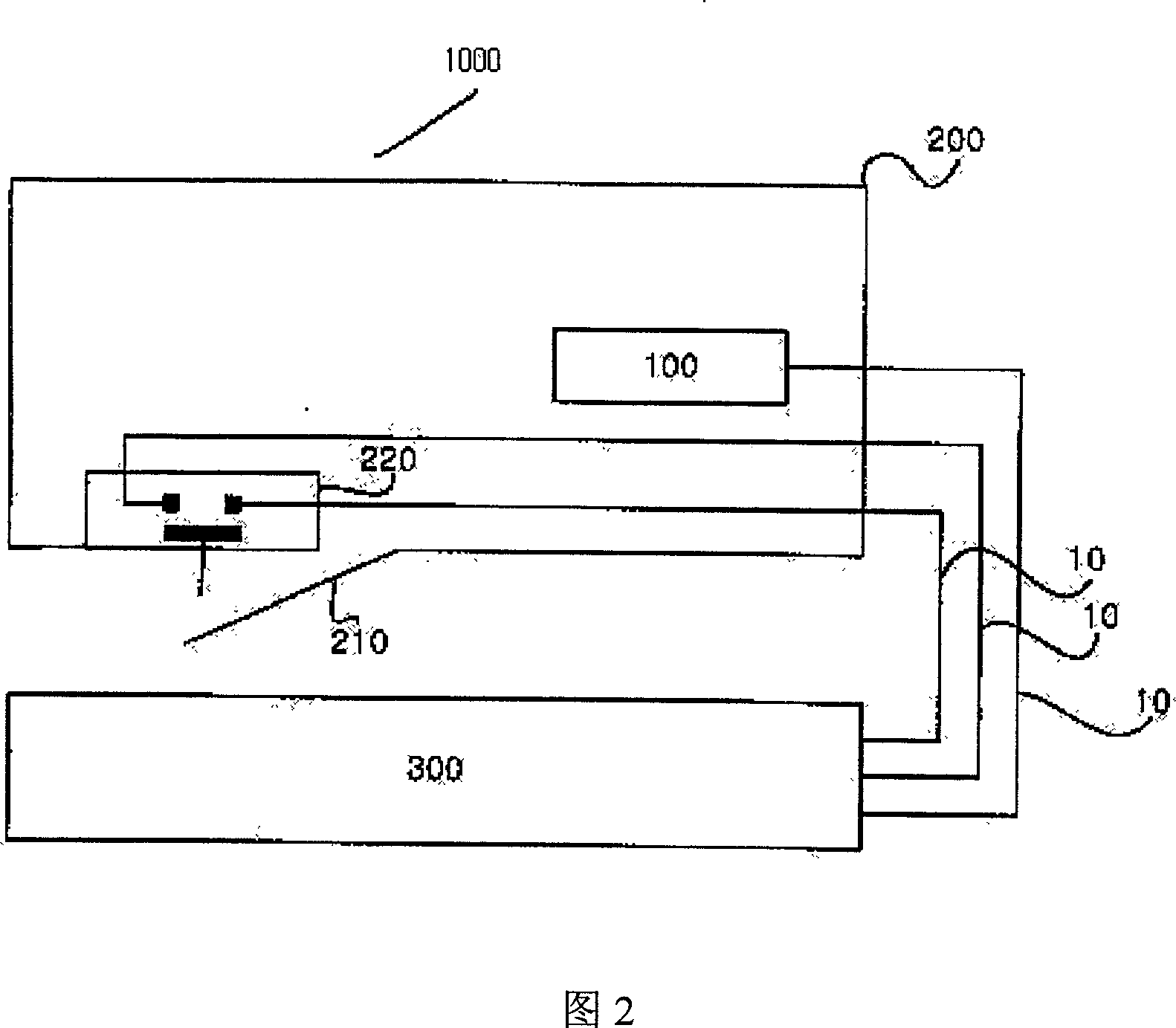

[0045] Fig. 2 is a structural diagram of an embodiment of the antistatic device utilizing soft X-rays of the present invention. As shown in the figure, the anti-static device 1000 includes an anti-static head 100 for generating soft X-rays, a soft X-ray protection part 200 that surrounds the anti-static head 100 and prevents the head 100 from leaking soft X-rays, and Make the head 100 generate an appropriate amount of soft X-rays to control the control signal for ion generation and the power control part 300 that provides control voltage for the head 100. The anti-static head 100 and the protection part 200 are controlled through the AC high voltage control cable 10 It is connected to the power control unit 300 .

[0046] The soft X-ray protection unit 200 that prevents leakage of soft X-rays is made of a steel plate with a thickness of 1 mm. The anti-static device 1000 also includes an interlock switch 220 for controlling the operation of the above-mentioned power control un...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com