Method and device for making prefabricated optical fibre

A technology for optical fiber preforms and manufacturing methods, which is applied in the direction of manufacturing tools, optical components, and glass manufacturing equipment, and can solve problems such as uneven growth of optical fiber preforms, unstable deposition processes, and large fluctuations in the core-to-core ratio. Surface cracking, elimination of air flow turbulence, and uniform outer diameter

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

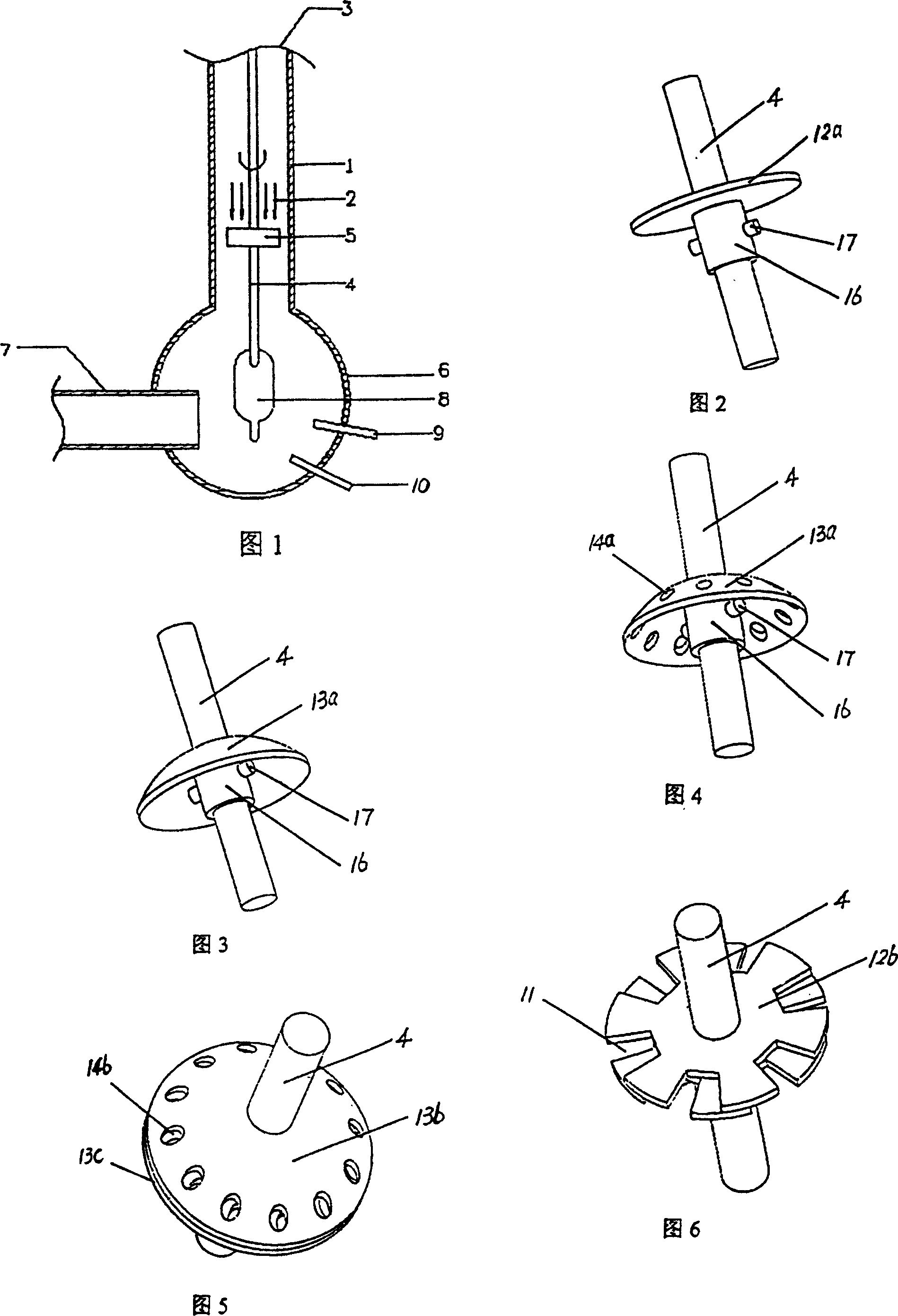

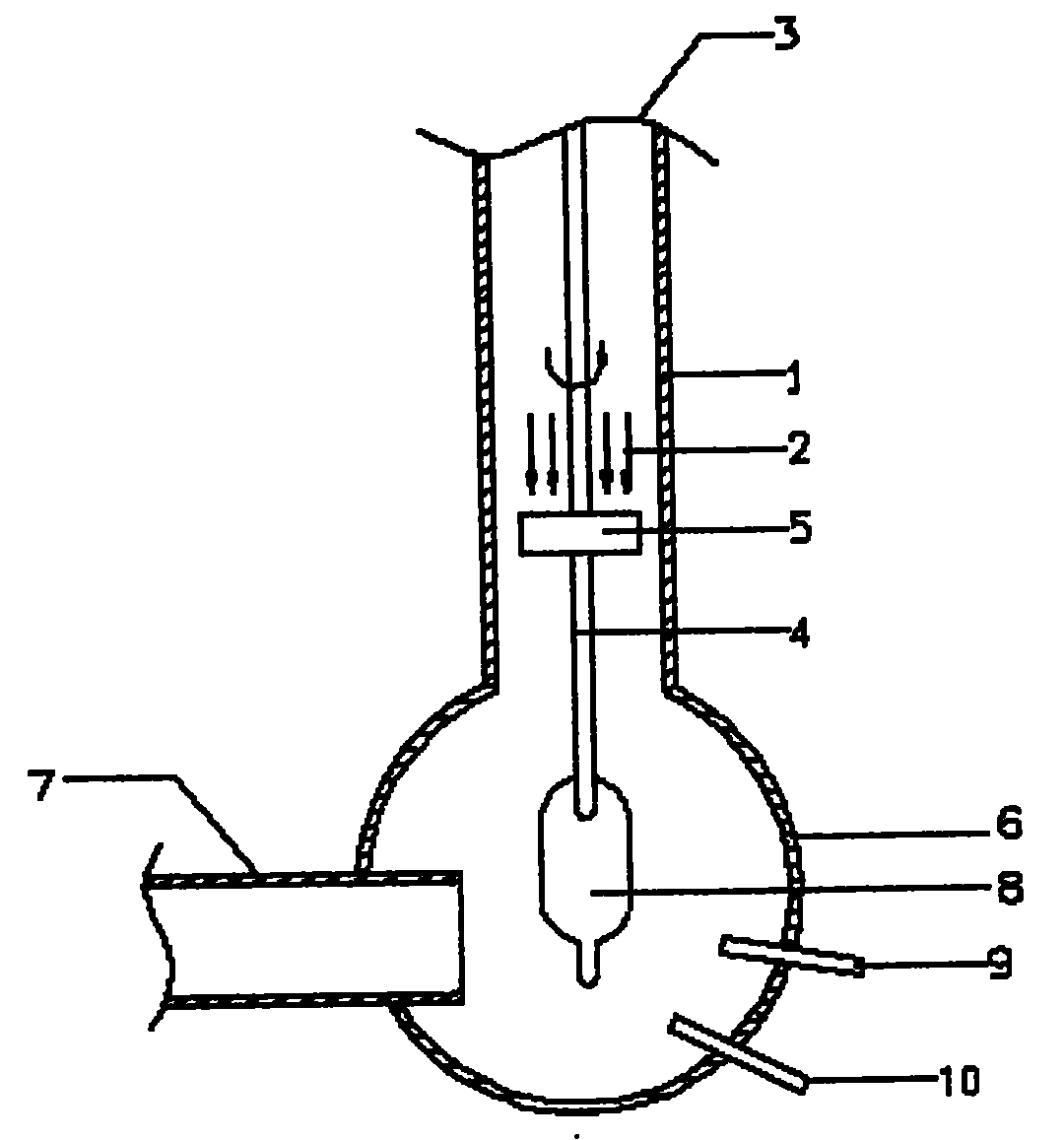

[0033] Embodiment 1: In the case of exhausting air from the exhaust port 7, first install the airflow regulator 5 with a diameter of 145mm on the seed rod 4 with a diameter of 25mm through the sliding sleeve 16 and the set screw 17, and then install the seed rod 4 Insert the air inlet 3 at the upper end of the flange pipe 1 with an internal diameter of 250mm into the spherical reaction vessel 6, and make the lower end of the seed rod 4 correspond to the two spray guns, rotate the seed rod at a uniform speed, and the exhaust port is connected with the exhaust fan. The pressure is controlled at about 100Pa, and the exhaust is started; the air inlet at the upper end of the flange tube is introduced into the reaction vessel with a pressure of about 0.5×10 5 Pa, air rectification air flow 2 with a temperature of about 20°C; then feed hydrogen and oxygen into the two spray guns, and ignite a hydrogen-oxygen flame at about 1000°C in the reaction vessel, and then feed the first spray g...

Embodiment 2

[0034] Embodiment 2: The difference from Embodiment 1 is that the pressure is about 2.0×10 from the air inlet on the upper end of the flange pipe into the reaction vessel. 5 Pa is heated to 600 ° C nitrogen rectification airflow 2; make the reaction in a balanced state for a certain period of time, you can get the predetermined requirements of the optical fiber preform; because the rectification airflow is selected from heated nitrogen with stable properties, it can be more Keep the temperature in the reaction vessel stable, and the reaction effect is better.

[0035] In the case of using an inert gas for the rectified gas flow, it is mainly because the stability of the inert gas is good, which can better ensure the stability of the reaction process.

[0036] For the three gases used to rectify the airflow, their temperature and pressure can be selected according to actual needs.

[0037] It should be noted that during the manufacturing process, the rectified airflow is limit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com