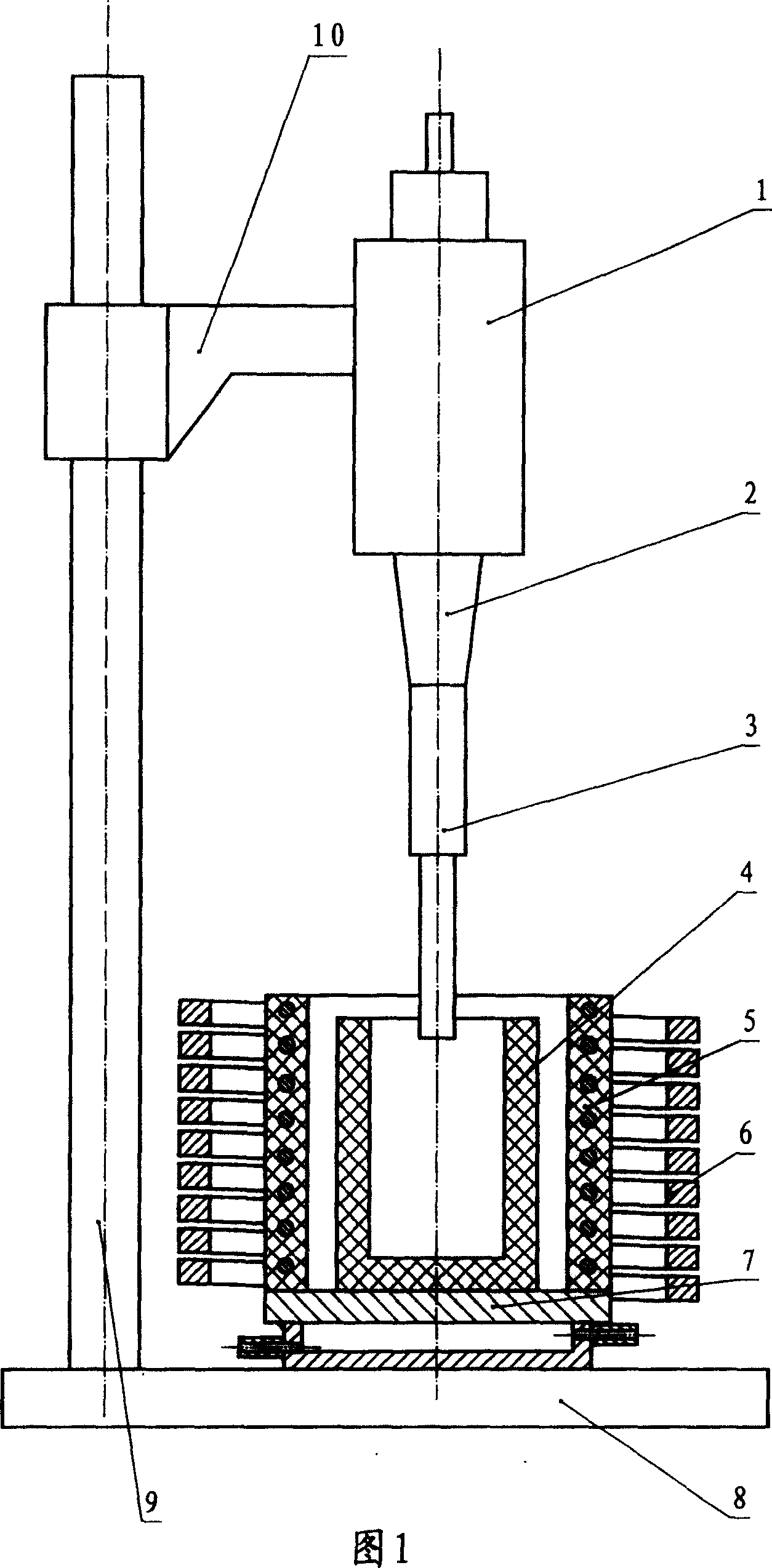

Method for preparing nanocystalline ingot casting by magnetic field and ultrasonic combined treatment of metal melt and dedicated apparatus therefor

A metal melt and combined processing technology is applied in the field of magnetic field and ultrasonic combined processing of metal melt to prepare nanocrystalline ingots. Simple production equipment and low investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] The specific steps of the present invention for the combined treatment of the metal melt with the magnetic field and the ultrasonic wave to prepare the nanocrystalline ingot are:

[0031] 1. According to the composition requirements of metal nanocrystalline ingots, the ingredients are prepared. Taking the low-melting point alloy Al-1.0% Cu as an example, put the prepared raw materials into the melting crucible, melt them, and overheat them by 10°C;

[0032] 2. Carry out degassing treatment on the metal melt, add a degassing refining agent to the metal melt, the amount of the degassing refining agent added is 0.8% of the weight of the metal melt, and the degassing time is 1 minute;

[0033] 3. Quickly pour the degassed metal melt into the preheated crucible, and the preheating temperature of the crucible is 300°C;

[0034] 4. Heat the poured metal melt to 100°C above the liquidus line with a heater;

[0035] 5. Constant temperature at this temperature, and apply electro...

Embodiment 2

[0039] 1. According to the composition requirements of the metal nanocrystalline ingot, the ingredients are prepared, taking the low-melting point alloy Pb-Sn as an example, put the prepared raw materials into the melting crucible, melt it, and overheat it at 50°C;

[0040] 2. Perform degassing treatment on the metal melt, blow nitrogen into the metal melt, and the degassing time is 8 minutes;

[0041] 3. Quickly pour the degassed metal melt into the preheated graphite crucible, and the preheating temperature of the crucible is 350°C;

[0042] 4. Heat the poured metal melt to 70°C above the liquidus line with a heater;

[0043] 5. Constant temperature at this temperature, and apply electromagnetic stirring to the metal melt, the excitation voltage is 200V, and the conduction current density is 10 8 A / m 2 , the magnetic flux density is 10T;

[0044] 6. At the same time, apply ultrasonic vibration to the metal melt, the ultrasonic power is 500W, the ultrasonic frequency is 10...

Embodiment 3

[0047] 1. According to the composition requirements of metal nanocrystalline ingots, the ingredients are prepared. Taking low-carbon steel Fe-0.1% C as an example, put the prepared raw materials into the melting crucible, melt them, and overheat them at 80°C;

[0048] 2. Degassing the metal melt, blowing argon into the metal melt, and the degassing time is 10 minutes;

[0049] 3. Quickly pour the degassed metal melt into the preheated graphite crucible, and the preheating temperature of the crucible is 400°C;

[0050] 4. Heat the poured metal melt to 10°C above the liquidus line with a heater;

[0051] 5. Constant temperature at this temperature, and apply electromagnetic stirring to the metal melt, the excitation voltage is 180V, and the conduction current density is 10 7 A / m 2 , the magnetic flux density is 8T;

[0052] 6. At the same time, apply ultrasonic vibration to the metal melt, the ultrasonic power is 100W, the ultrasonic frequency is 60kHz, and the time for apply...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com