Process method for regenerating foamed plastic from waste polyester bottles and printed circuit boards

A technology for printed circuit boards and foamed plastics, applied in plastic recycling, bulk chemical production, recycling technology, etc., can solve the problems of high equipment cost, limited use and added amount, etc., and achieve high economic value and cost advantages , Wide application prospects, the effect of low relative density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

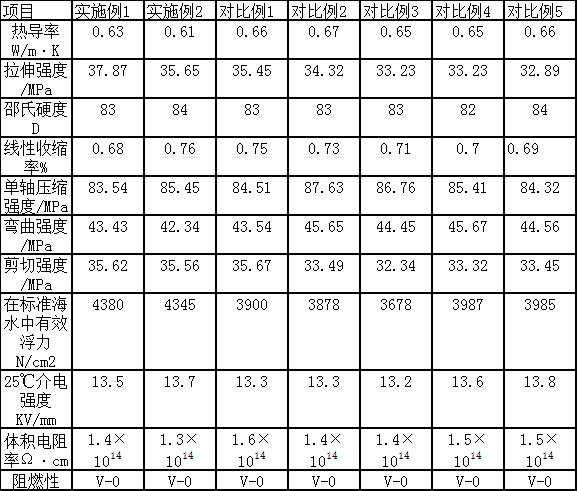

Examples

Embodiment 1

[0014] A kind of processing method of waste polyester bottle and printed circuit board regenerated foamed plastics, comprises the following steps:

[0015](1) Put the waste printed circuit board powder and the plasticized ionic liquid with 1.5 times the weight of the waste printed circuit board powder in the organic solvent with 0.7 times the weight of the waste printed circuit board powder to heat, and the waste printed circuit board powder increases Under the catalysis of plastic ionic liquid, a degradation reaction occurs, the reactor is evacuated, and then filled with CO 0.4 times the weight of waste printed circuit board powder. 2 Gas, react at 280°C and 30MPa in a supercritical state for 0.8 hours, then cool naturally to room temperature to obtain a solid-liquid mixture; (2) Add epoxy butyl catallate into the reactor, and heat up to 160°C within 2 hours , then add 2.4 times the weight of epoxy butyl catallate to the solid-liquid mixture obtained in step (1), finish addin...

Embodiment 2

[0019] A kind of processing method of waste polyester bottle and printed circuit board regenerated foamed plastics, comprises the following steps:

[0020] (1) Put the waste printed circuit board powder and the plasticized ionic liquid with 1 times the weight of the waste printed circuit board powder in an organic solvent with 0.4 times the weight of the waste printed circuit board powder to heat, and the waste printed circuit board powder increases Under the catalysis of plastic ionic liquid, a degradation reaction occurs, and the reactor is evacuated, and then filled with CO with 0.2 times the weight of waste printed circuit board powder. 2 Gas, react at 260°C and 26MPa in a supercritical state for 0.5 hours, then cool naturally to room temperature to obtain a solid-liquid mixture; (2) Add epoxy butyl catallate into the reactor, and heat up to 160°C within 2 hours , then add 2.2 times the weight of epoxy butyl catallate to the solid-liquid mixture obtained in step (1), finis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com