Method for extracting spore oil from exosporium-broken spore of glossy ganoderma

A technology of broken spores of Ganoderma lucidum and Ganoderma spore oil, which can be used in medical formulas, medical preparations containing active ingredients, plant raw materials, etc., and can solve the problems of destruction of active ingredients of Ganoderma lucidum spores, affecting the effect of medical care, and high temperature of chemical extraction. To achieve the effect of guaranteed health care effect, short extraction time and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

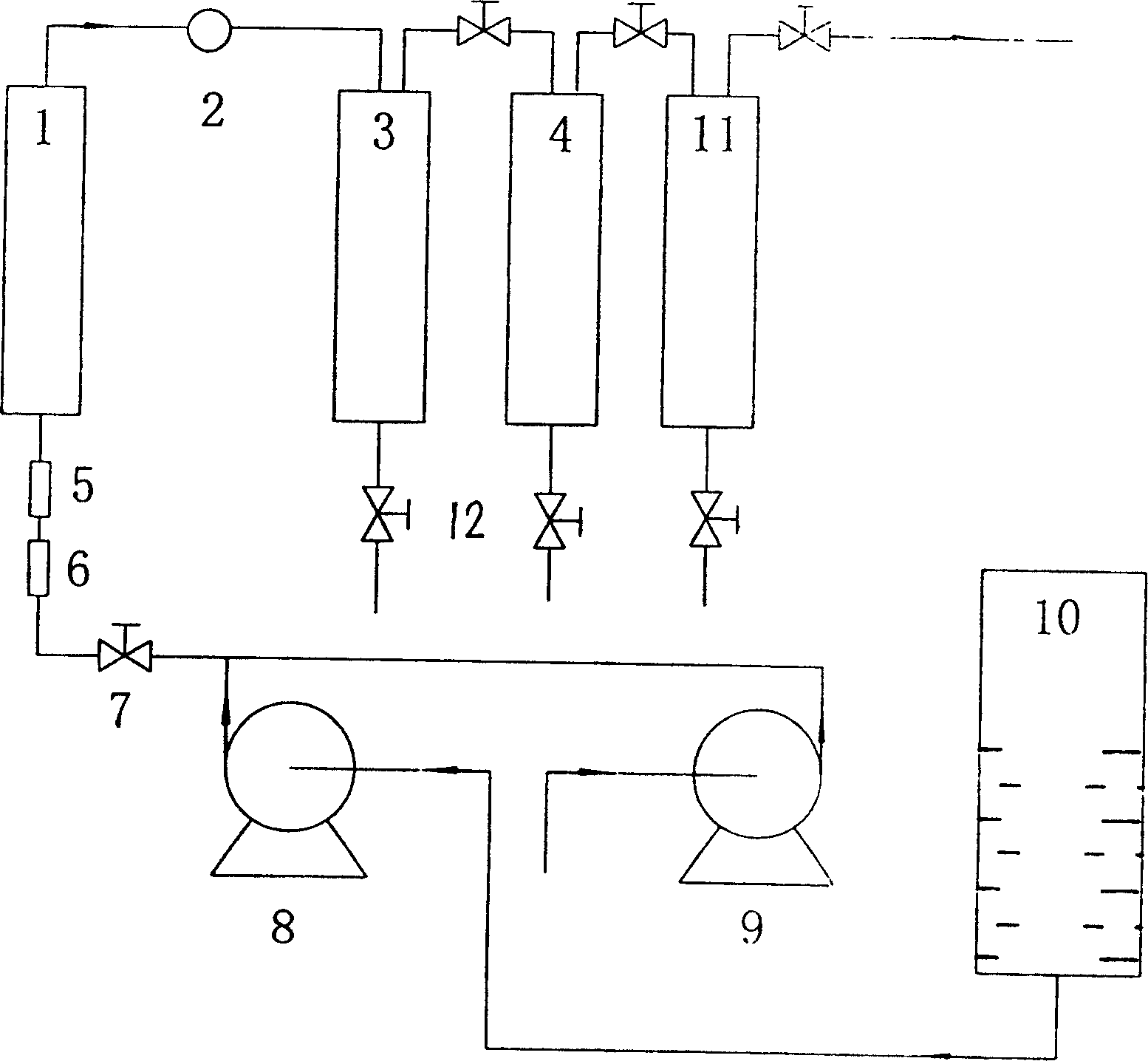

[0019] Based on the total composition of Ganoderma lucidum broken spore powder, Tianqing powder and water, the proportions of 80% Ganoderma lucidum broken spore powder, 1.2% Tianqing powder and 20% of water are mixed uniformly, squeezed into strips, and dried. As shown in Figure 1, take 50Kg of dried Ganoderma lucidum spores mixed powder into supercritical extractor 1, open the feed valve 7, filter 6, the carbon dioxide will fill the extractor 1, until the carbon dioxide storage tank 10 and the extractor 1 After the pressure is equalized, turn on the preheating temperature controller 5 to raise the carbon dioxide to 60°C, turn on the carbon dioxide feed pump 8 so that the pressure of the extractor 1 reaches 30Mpa through the pressure controller 2, and at the same time turn on the edible alcohol feed pump 9 After 30 hours of extraction, the extract enters the No. 1 decompression separator 3 and No. 2 decompression separator 4 through the top of the extractor 1, CO 2 The gas is disc...

Embodiment 2

[0021] Based on the total composition of Ganoderma lucidum broken spore powder, Tianqing powder and water, the proportions of 88% Ganoderma lucidum broken spore powder, 0.2% Tianqing powder and 10% of water are mixed uniformly, squeezed into strips, and dried. Figure 1

[0022] As shown, take 50Kg of dried Ganoderma lucidum spores mixed powder into the supercritical extractor 1, open the feed valve 7, the filter 6, the carbon dioxide will fill the extractor 1, and wait for the pressure of the carbon dioxide storage tank 10 and the extractor 1 to balance After that, turn on the preheating temperature controller 5 to heat the carbon dioxide to 45°C, turn on the carbon dioxide feed pump 8 so that the pressure of the extractor 1 reaches 20Mpa through the pressure controller 2, and at the same time turn on the edible alcohol feed pump 9 to extract 5 After hours, the extract enters the No. 1 decompression separator 3 and No. 2 decompression separator 4 through the top of the extractor 1...

Embodiment 3

[0024] Based on the total composition of Ganoderma lucidum broken spore powder, Tianqing powder and water, 85% Ganoderma lucidum broken spore powder, 0.6% Tianqing powder, and 14.4% of water are mixed uniformly, extruded into a strip shape, and dried. As shown in Figure 1, take 50Kg of dried Ganoderma lucidum spores mixed powder into supercritical extractor 1, open the feed valve 7, filter 6, the carbon dioxide will fill the extractor 1, until the carbon dioxide storage tank 10 and the extractor 1 After the pressure is equalized, turn on the preheating temperature controller 5 to raise the carbon dioxide to 50°C, turn on the carbon dioxide feed pump 8 so that the pressure of the extractor 1 reaches 25Mpa through the pressure controller 2, and at the same time turn on the edible alcohol feed pump 9 After 25 hours of extraction, the extract enters the No. 1 decompression separator 3 and No. 2 decompression separator 4 through the top of the extractor 1, CO 2 The gas is discharged fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com