Polishing method of diamond material

A diamond and polishing disc technology, which is applied in the direction of polishing machine tools, metal processing equipment, manufacturing tools, etc., can solve problems such as limited roughness, achieve good polishing surface quality, improve polishing efficiency, and reduce polishing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0064] The diamond material is CVD diamond film, the surface roughness is 3-8μm, and the polishing area is 1.1cm 2 ; Polishing dissolved salt oxidant composed of LiNO 3 +KNO 3 , molar ratio (0.43-0.4): (0.57-0.60), melting point 130°C. The pressure is 0.2MPa, the rotation speed of the polishing disc is 81RPM, the cast iron disc, the grinding disc temperature is 150°C, and the surface roughness Ra value after polishing reaches 0.4m.

Embodiment 2

[0066] The diamond material is CVD diamond film, the surface roughness is 3-8μm, and the polishing area is 1.1cm 2 ; Polishing dissolved salt oxidant composed of LiNO 3 +KNO3 , molar ratio (0.43-0.4): (0.57-0.60), melting point 130 ° C; LiNO 3 +KNO 3 , aluminum disc, grinding disc temperature 150 ℃.

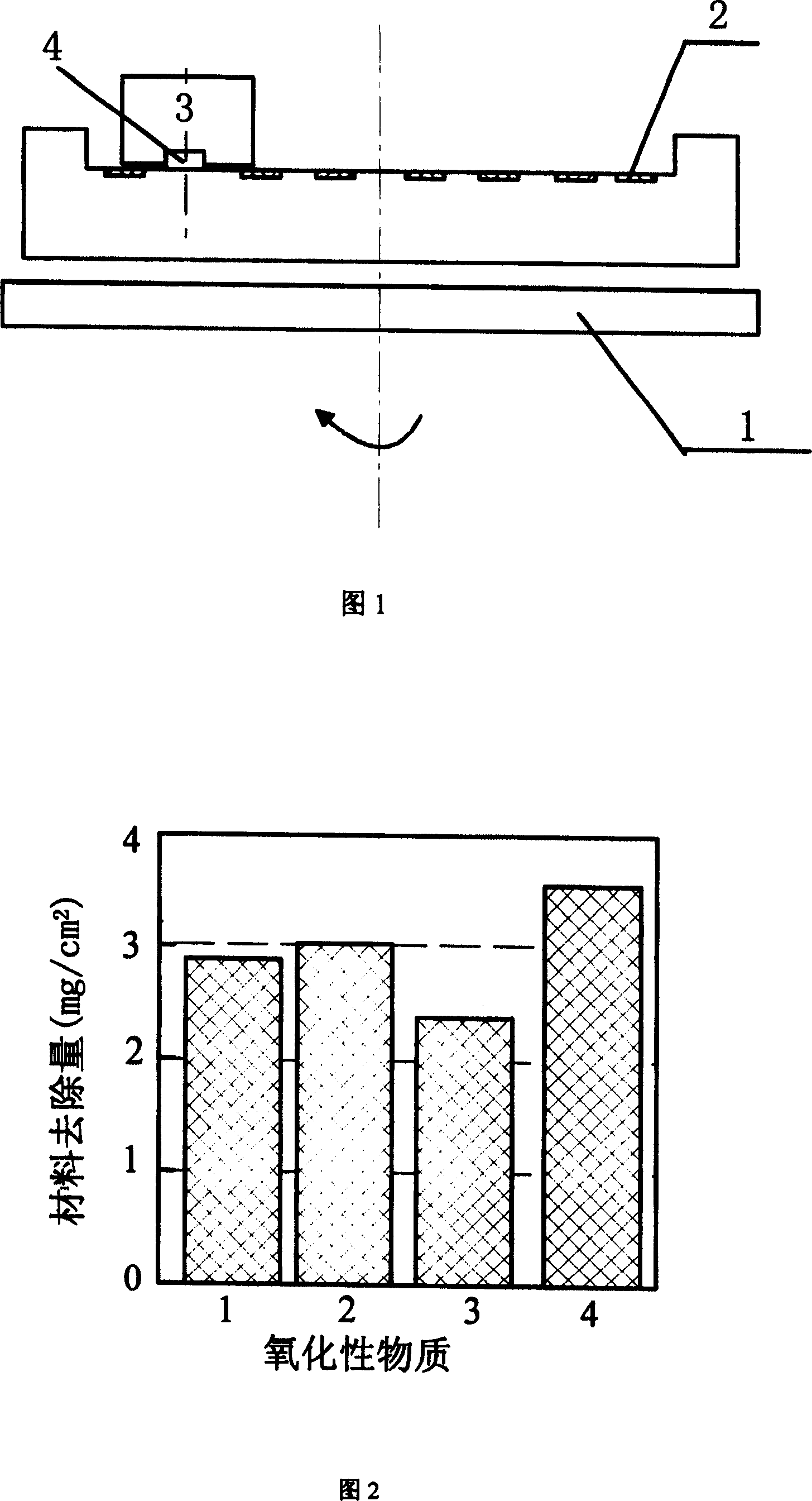

[0067] As shown in Figure 2, the comparison uses NaOH, KNO 3 ,NaOH+KNO 3 Comparison of material removal rate of diamond film polished by three substances as oxidant (temperature 320°C). From these four kinds of methods, use technique of the present invention and dissolved salt oxidant LiNO at lower temperature 3 +KNO 3 the largest amount of removal.

Embodiment 3

[0069] The diamond material is natural single crystal diamond with a surface roughness of 0.2; the composition of the polished dissolved salt oxidant is LiCL+LiNO 3 +NaNO 3 , molar ratio 0.05:0.80:0.15, melting point 174°C. The pressure is 0.3MPa, the speed is 150RPM, the cast iron disc, and the Ra value reaches 0.02m.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com