Calcium phosphate cement and use and method for making same

A technology of calcium phosphate salt and cement, which is applied in application, dental preparations, compression molding cups, etc. It can solve the problems of operation time, solidification time not meeting the requirements, inability to solidify, and difficulty in adjustment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Embodiment 1: heat treatment method

[0037] Ca(H 2 PO 4 ) 2 ·H 2 5 gm of O powder and 1.6 ml of 25 mM dilute phosphoric acid aqueous solution were thoroughly mixed and stirred for one minute, then placed in an oven at a constant temperature of 50°C for 15 minutes, the obtained dry mixture was taken out, and then ground for 20 minutes with a mechanical grinder to pulverize into fine particles. After weighing 1 gm of fine particles and mixing with 0.4 ml (1.0 M, pH=6.0) of phosphate aqueous solution to form a paste, the working time and setting time of the obtained paste were measured every 30 seconds. The work time is the time after the paste is complete that it becomes too viscous to be stirred. The setting time is the time a needle with a diameter of 1 mm can only penetrate the paste to a depth of 1 mm with an applied force of 1 / 4 pound. The operating time of the paste of this embodiment is 30 minutes, and the setting time is 1 hour.

[0038] The paste of this e...

Embodiment 2

[0039] Embodiment 2: vacuum treatment method

[0040] CaHPO 4 (DCPA) powder 5gm and 1.2ml of 25mM dilute phosphoric acid aqueous solution are fully mixed and stirred for one minute, placed in a vacuum environment of -100Pa and pumped for 30 minutes, wait until it is completely dry, take it out and grind it with a mechanical grinder for 20 minutes, and crush it into fine particles. After weighing 1 gm of fine particles and mixing with 0.4 ml (1.0 M, pH=6.0) phosphate aqueous solution to form a paste, the operation time and setting time of the paste were measured every 30 seconds. The operating time of the paste of this embodiment was 20.5 minutes, and the setting time was 24.0 minutes.

[0041] The paste of this example was placed in a large volume of deionized water immediately after formation and it was observed that the paste did not disperse. Embodiment 3: organic solvent treatment method

Embodiment 3

[0041] The paste of this example was placed in a large volume of deionized water immediately after formation and it was observed that the paste did not disperse. Embodiment 3: organic solvent treatment method

[0042] Mix 5gm of DCPA powder with 1.6ml of 25mM dilute phosphoric acid aqueous solution and stir for one minute, then add 1.6ml of acetone to make the paste fully mixed, then place it in a vacuum environment of -100Pa for 1 hour until it is completely dry Take it out and grind it with a mechanical grinder for 20 minutes, and crush it into fine particles. After weighing 1 gm of fine particles and mixing with 0.4 ml (1.0 M, pH=6.0) phosphate aqueous solution to form a paste, the operation time and setting time of the paste were measured every 30 seconds. The operating time of the paste of the present embodiment is 20.0 minutes, and the setting time is 22.0 minutes.

[0043] The paste of this example was placed in a large volume of deionized water immediately after form...

PUM

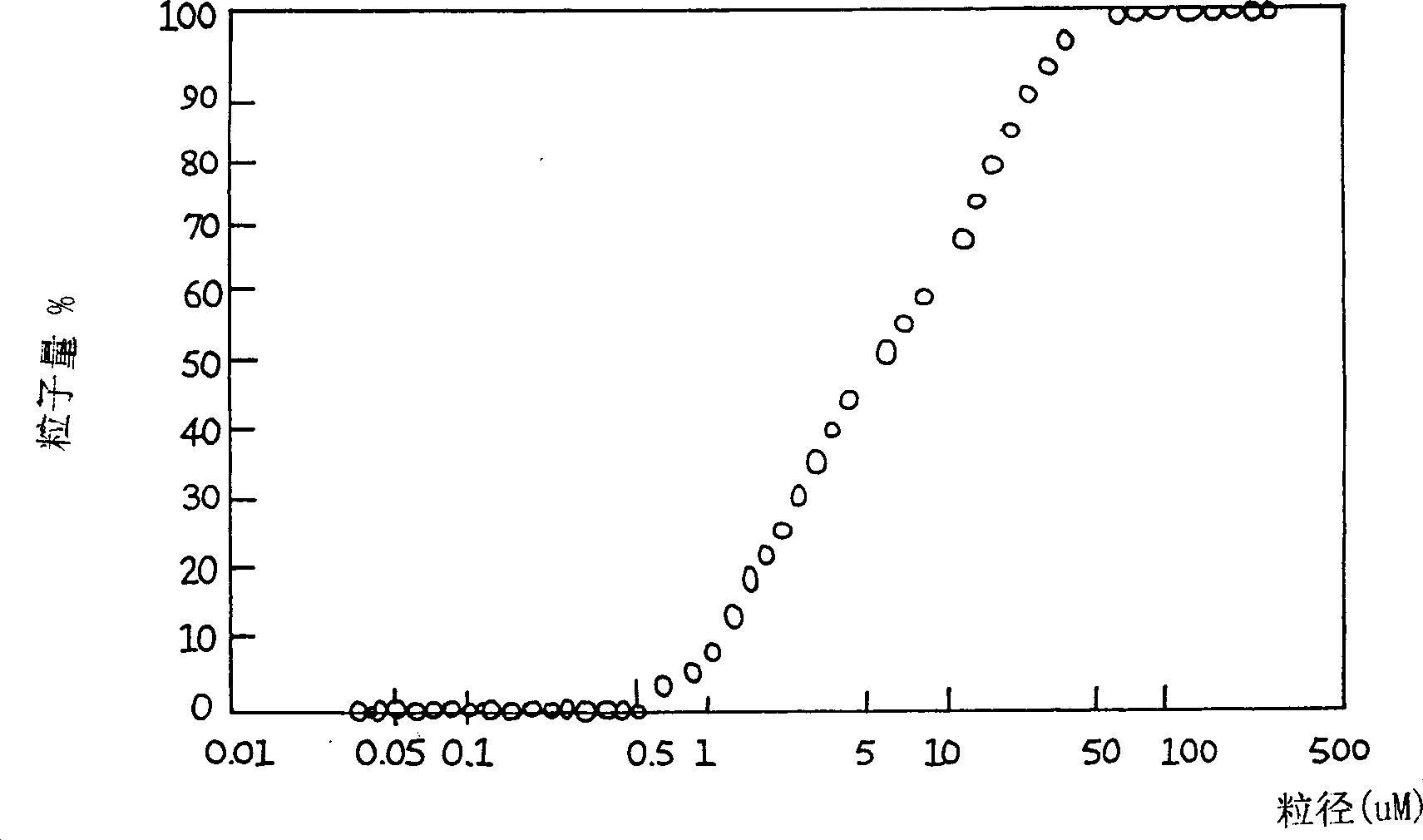

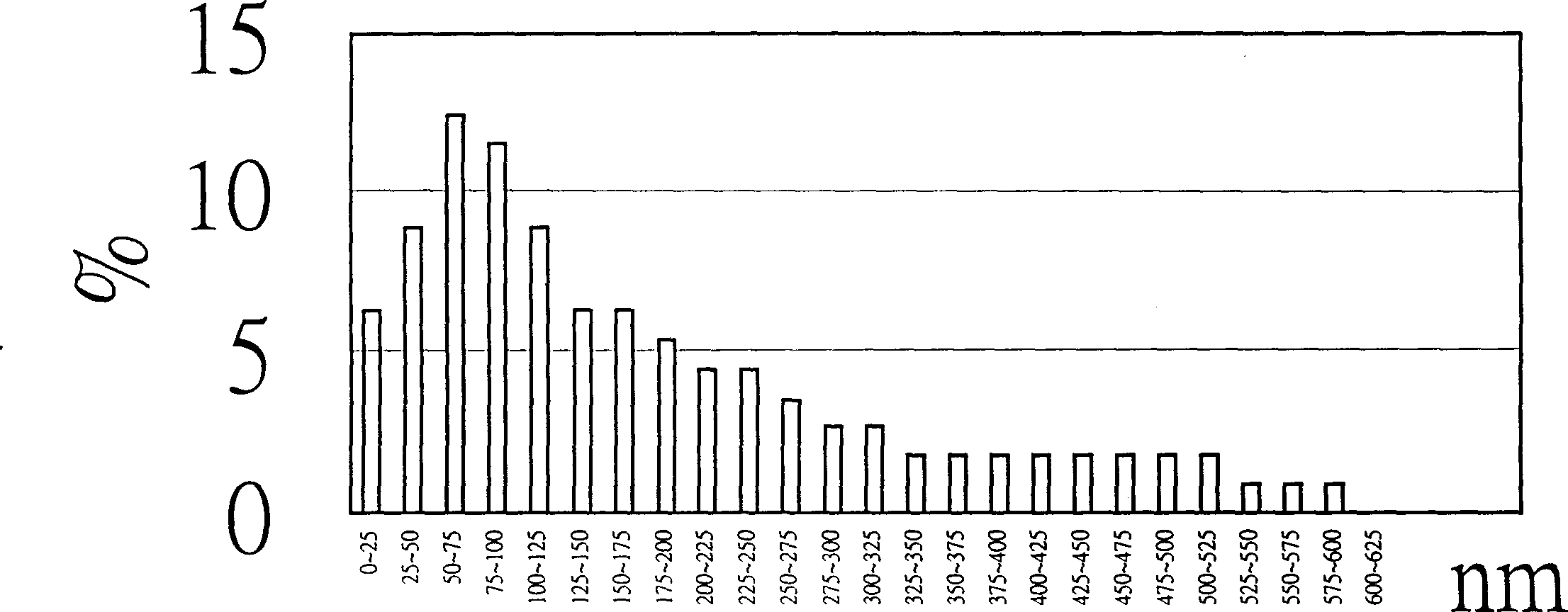

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com