Oxide superconductive wire material making method and heat treatment apparatus for said method

A technology of superconducting wire rod and manufacturing method, which can be applied in the manufacture/processing of superconductor devices, cable/conductor manufacture, superconductive devices, etc., and can solve problems such as inability to effectively prevent gas expansion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

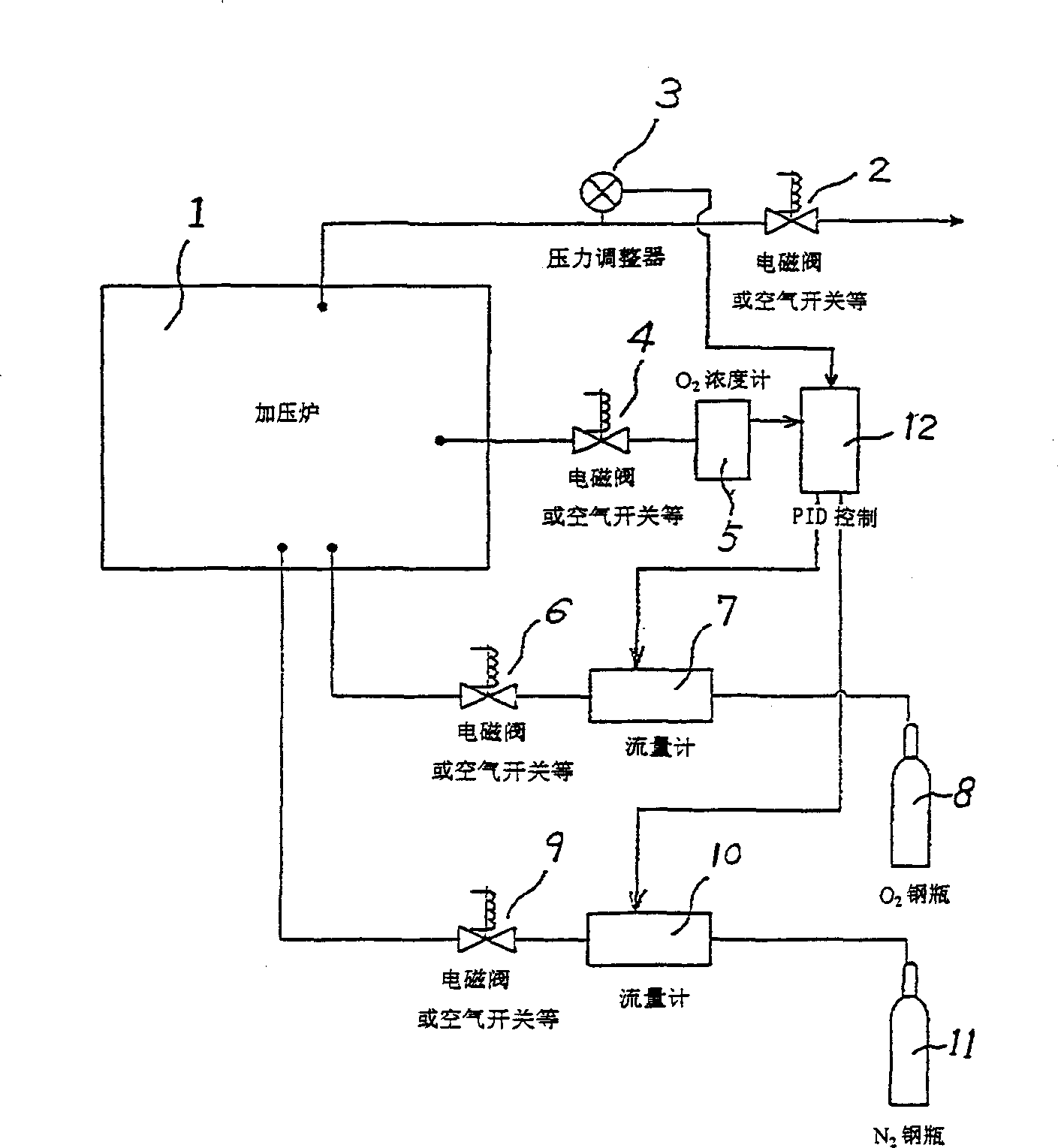

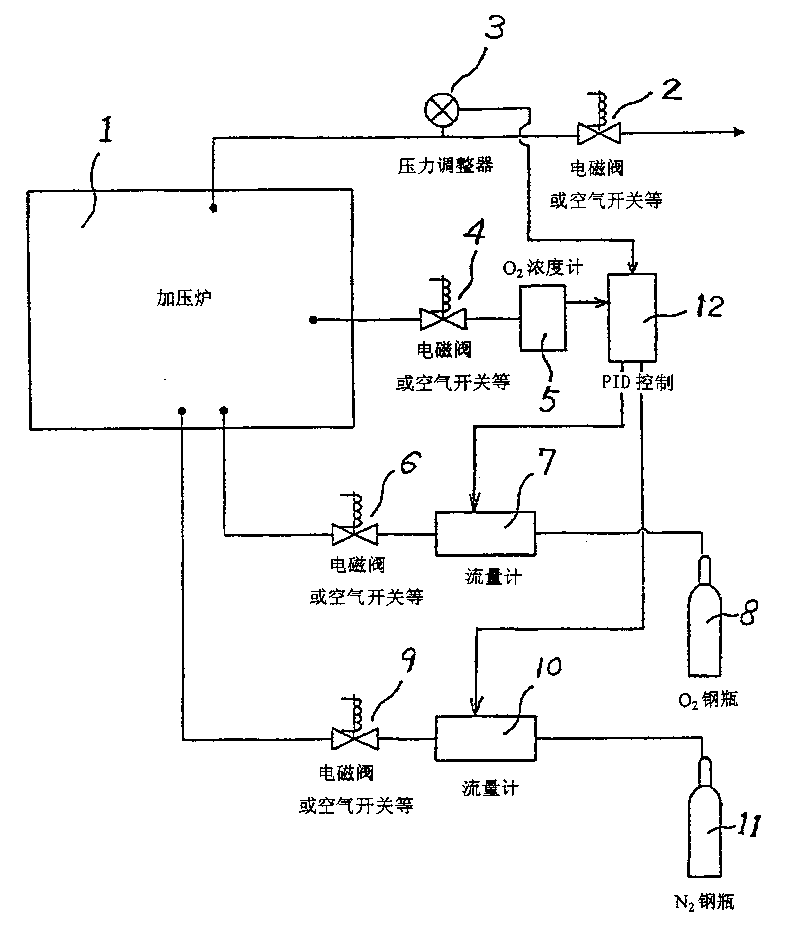

Method used

Image

Examples

Embodiment 1

[0045] Use Bi 2 o 3 , PbO, SrCO 3 , CaCO 3 , CuO compound powders were used as raw material powders of bismuth-based oxide superconductors to prepare mixed powders such that the composition ratio Bi:Pb:Sr:Ca:Cu=1.82:0.33:1.92:2.01:3.02. After the mixed powder was heat-treated at 750°C for 10 hours, it was further heat-treated at 800°C for 8 hours. This heat-treated mixed powder was further pulverized with an automatic mortar. The powder obtained by this pulverization was heat-treated at 850°C for 4 hours, and then pulverized by an automatic mortar.

[0046] The powder thus obtained was heat-treated under reduced pressure, and filled in a silver tube having an outer diameter of 36 mm and an inner diameter of 30 mm. The powder-filled silver tube is then wire-drawn. A bundle of 61 obtained wire rods was embedded in a silver tube with an outer diameter of 36 mm and an inner diameter of 31 mm, and stretched and pressed. Said press processing is carried out at a squeeze ratio...

Embodiment 2

[0053] In the same manner as in Example 1, a strip-shaped bismuth-based oxide superconductor wire was produced. The obtained wires are separated by ceramic paper made of a mixture of alumina fiber and zirconia powder, which is used as a gap material, and the wires are overlapped, and wound in this state on a stainless steel wire with a diameter of 50 cm. on the shelf. Then, the initial conditions of pressurization and decompression were changed as shown in Table 2, and each sample wire was heat-treated under the conditions of total pressure 1.0MPa, oxygen partial pressure 0.02MPa, heat treatment temperature 840°C, and heat treatment time 50 hours. The degree of expansion of the wire rod after heat treatment was evaluated, and the results are shown in Table 2.

[0054] sample №

[0055]The data in Table 2 shows that in the heat treatment step in the pressurized atmosphere gas, the pressure is increased before the temperature is raised, or after the decompression star...

Embodiment 3

[0057] In the same manner as in Example 1, a strip-shaped bismuth-based oxide superconductor wire was produced. The obtained wires were separated by ceramic paper used as a gap material made of a mixture of alumina fibers and zirconia powder, and the wires were wound on a stainless steel winding frame with a diameter of 50 cm in a state where the wires were overlapped. Next, heating was started after applying predetermined pressure, and heat treatment was performed under predetermined conditions. Cool to room temperature after heat treatment, then release the pressure.

[0058] The first heat treatment was performed at a heat treatment temperature of 810° C. and a heat treatment time of 50 hours in a pressurized atmosphere gas having a total pressure of 1.0 MPa and an oxygen partial pressure of 0.005 MPa. Next, each sample wire rod was subjected to press processing at a pressing ratio of 15%, and then subjected to a second heat treatment by changing the partial pressure of ox...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com