Magneto-optical recording target material and its preparing process

A technology of magneto-optical recording and production process, applied in the fields of magnetic recording, data recording, recorded information storage, etc., which can solve the problems of non-centralized research and variable alloy composition.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

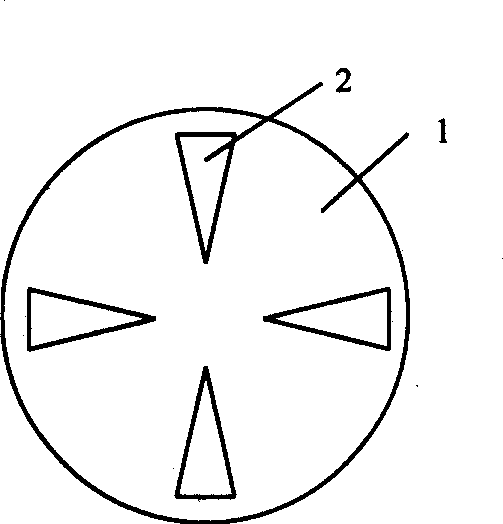

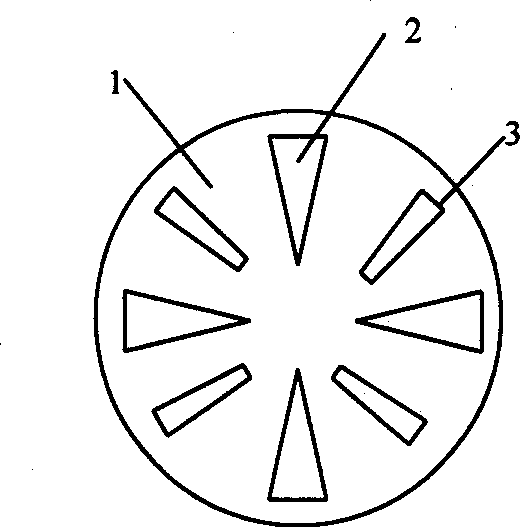

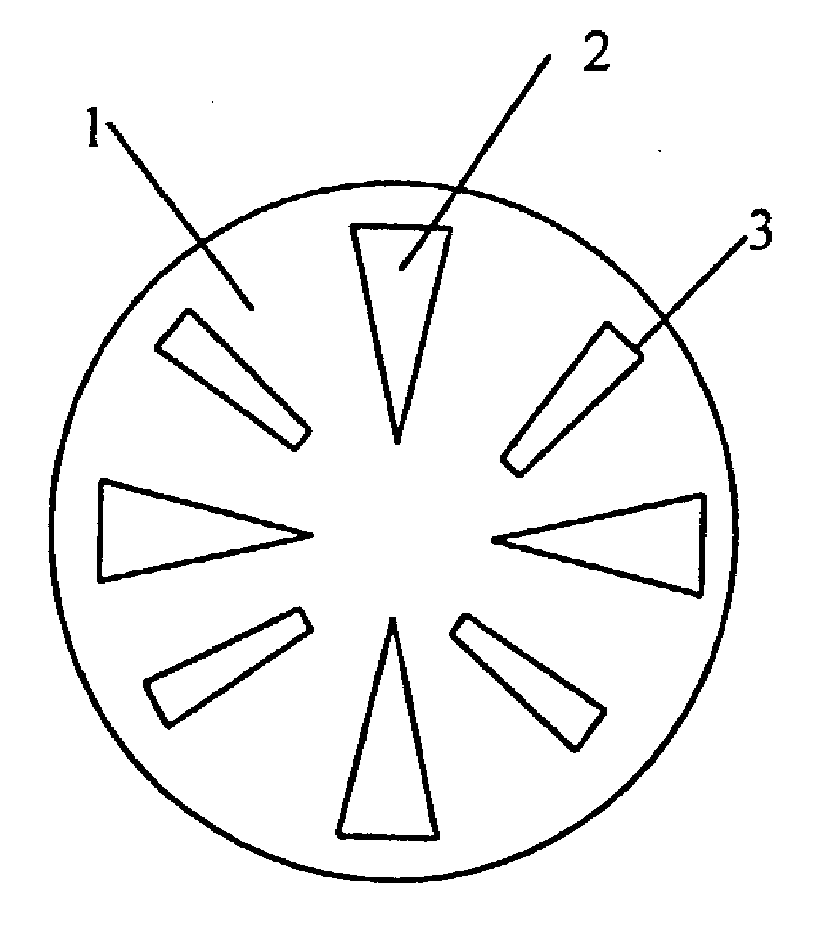

[0012] The process of preparing the magneto-optical target is as follows: Process 1 raw material treatment and ingredients: surface chemical treatment of industrial pure iron, and then refining terbium, light rare earth and iron in a magnetic suspension furnace; at the same time, the cobalt is also properly surface treated ; Finally, dosing under the protection of inert gas: The dosing elements and components of various targets are consistent with the above-mentioned composite targets. The base target alloy is smelted by the magnetic levitation melting technology, and the alloy composition of the base target 1 is iron-cobalt (FeCo) alloy. Cut pure terbium 2 (Tb) and light rare earth 3 (LRE) wires into segments or disks, and symmetrically inlay them in the circular area with the largest etching of the iron-cobalt alloy-based target 1 to make a composite target, such as figure 1 with 2 As shown, the composition of the target can be changed by adjusting the number and position o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com