Electrochemical biosensor test strip, fabrication method thereof and electrochemical biosensor

A biosensor and electrochemical technology, applied in the field of electrochemical biosensors, can solve the problems of easy disengagement, low detection efficiency, and difficult fixation of reagents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

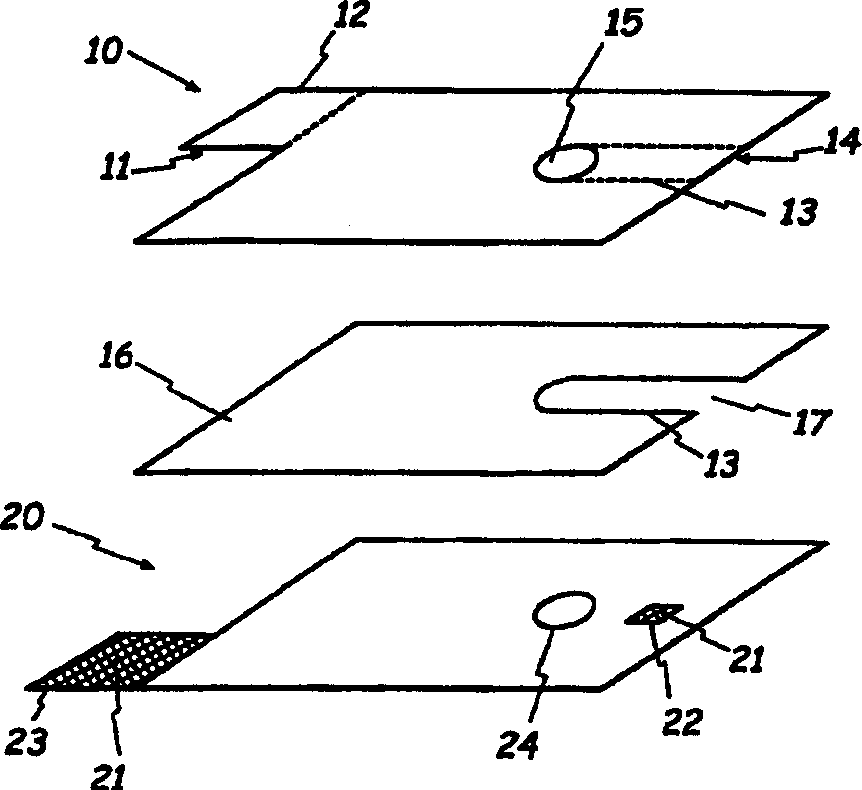

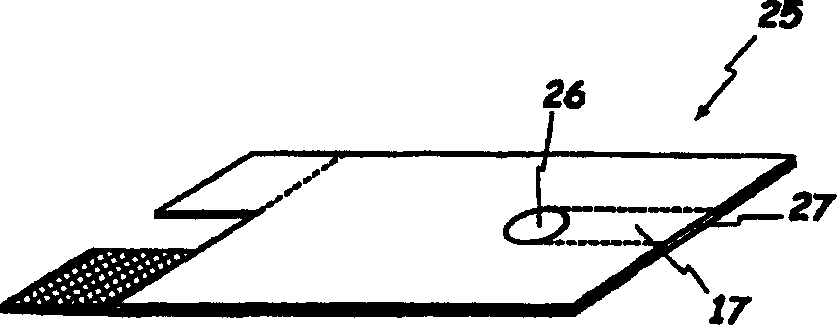

[0026] Preferred embodiments of the present invention may be best understood with reference to the accompanying drawings. In the drawings, the same reference numerals denote the same and corresponding parts, respectively. The preferred embodiments are for illustrative purposes only and are not intended to limit the invention.

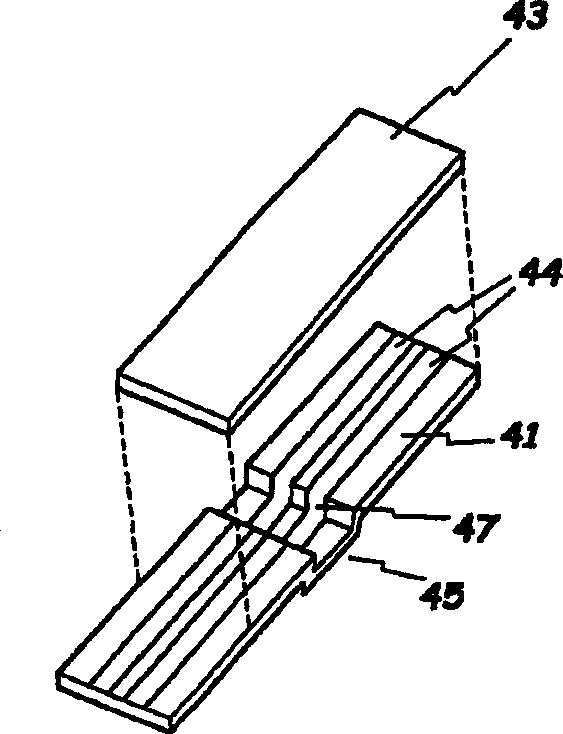

[0027] 2 is a perspective view schematically showing the structure of a test strip of an electrochemical biosensor according to the present invention. As can be seen from the figure, the test strip of the electrochemical biosensor of the present invention comprises an insulating substrate 41 or 42 on which a press working or vacuum molding method ( Figure 2A ). Imprint or by etching ( Figure 2B ) to form grooves 45 or 46. The electrode 44 is mounted on the insulating substrate 41 or 42 . The grooves 45 or 46, whether stamped or etched, function to ensure that the corresponding reagent (not shown) is immobilized thereon.

[0028]In this structure...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com